1. Cooper-Helmstetter concept:

When a bacteria divides more frequently than at 60 minutes intervals, a cycle of replication is initiated before the end of every 35 minutes.

This may be taken as an example. The cycle of replication connected with a division must have been initiated 25 minutes before the preceding division.

This situation as presented in literature shows the chromosomal complement of a bacterial cell at 5 minutes intervals throughout the cycle. It has been shown that at division (35/ 0 minutes) the cell receives a partially replicated chromosome. The replication fork continues to advance. At 10 minutes when this old replication fork has not yet reached the terminus, initiation occurs at both origins on partially replicated chromosome. The start of these new replication forks creates a multi fork chromosome.

2. Growth in relation to replication initiation time point:

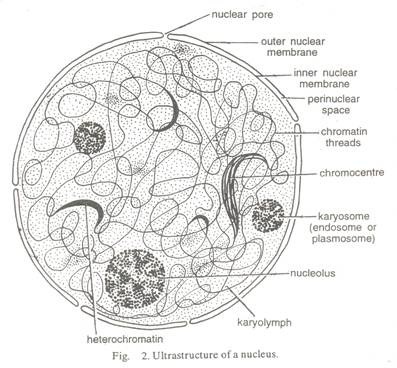

The events of engineering cell biology of bacteria in growth phases in terms of segregation mechanism of attachment of DNA to membrane in a batch culture could be represented by a pictorial model (Fig. 2.2). This model, however, did not indicate the connection of age of the cell at initiation and inter-initiation time (IIT).

This connection is important in understanding frequency of initiation from ori C as a function of cell growth rate. Realizing this limitation in the above mentioned pictorial model its extension in terms of cell division cycle time components of a new born cell has been analyzed (Fig. 2.3). Also, bacterial subcellular molecular engineering biology components, e.g. chromosome and plasmid are contributing significantly in bioprocess engineering by participating in developing technologically redesigned bio cells or enzymic protein bio catalysis for specific product formation. Now its examples are many.

3. Translation of replication knowledge to bioprocess engineering:

It is evident that both chromosomal and plasmid replication are important in the manifestation of cell biology behaviour in product forming culture.

Information of faster or slower growth rate of cells is important in bioprocess engineering design in terms of:

(a) Transient analysis,

(b) Maximum specific growth rate/dilution rate,

(c) Optimization of growth related variables,

(d) Stability of trans formant,

(e) Oxygen responses in trans formant cells and

(f) Expression of trans formant in scale up system and varying bioprocessing strategy.

Analysis of many of these aspects with bacterial cultures is in progress.

4. Concept of stability and steady state in cell division:

(i) Physical Basis:

Cell cultures if grown in a batch system are unstable. Non-equilibrium or instability in terms of growth and product formation exhibited for obvious reasons. Also, some organisms grow quickly, some at relatively intermediate rate while others slowly even in the best medium. Cell growth instability however relates to physical, chemical and genetic basis.

For overcoming this instability disadvantage the concept of ‘inflow’ and ‘outflow’ for continuous linkage between DNA replication and cell division in nutrients was conceived. As per this concept by inflow of fresh nutrients and concomitantly to the outflow of a portion of culture it would be possible theoretically to maintain the logarithmic growth rate or steady balanced cell division/growth infinitely.

In other words ‘steady state’ growth of cultures is possible. Such ‘steady state’ cultures have indeed been achieved, if not infinitely, at least for several days in many systems although mostly in laboratory scale by using appropriate cell cultivation strategy. One of the primary factors influencing the logarithmic or steady state growth of the culture relates to the inherent character of the organism. Instability and non-equilibrium condition cause non-uniformity in growth rate and other parameters in the bio-system and is disadvantageous in process biotechnology development.

However, steady state or stability of growth depends on many external factors. The concentration of nutrient(s) at very low levels can limit the rate. If the medium contains all but one of the essential nutrients in excess, both the growth rate and total density of the cell population will then depend on the concentration of this limiting factor in the growth medium.

This principle in form of exogenous “differential feeding” can be used to regulate ‘steady state’ growth of cells. Under such exogenous control both the flow rate and the medium concentration of one essential nutrient are arbitrarily fixed at values that result in less than maximum growth rate of the system.

As the culture density increases from the inoculum, the limiting factor is taken up to provide the irreducible individual requirement for more and more cell biomass and the concentration of this factor in the medium become progressively lower and lower. In time, the concentration will reach the very low level at which it limits growth rate, where upon the growth rate will decrease until it just balances the flow rate.

At this point the culture is stabilized and will thereafter maintain a constant cell density. This mode of cell cultivation is termed as continuous culture. Stabilized or steady state system is important in kinetic studies on genetic mutation, enzymic adaptation and should offer a valuable approach to the investigation of the synthesis of cell protoplasm. It can also provide larger biomass yield of cells per unit volume of medium than is possible in classical closed system batch method.

(ii) Microbial Engineering Basis:

Two mechanisms for regulation of continuous culture are:

(a) Internal control or turbidostat/biogen and

(b) External control or ‘chemostat’.

In ‘turbidostat’ the cell propagation is held constant by a device that measures the culture turbidity and regulates the feed and simultaneously, of course, the withdrawal, accordingly. It means that if the cell population rises above the set levels the proportional speed control pump adds medium at an increased rate until it returns; if the population falls too low the pump adds medium at a reduced rate until it returns to set level.

For adequate response it is necessary to operate a turbidostat in or near ‘exponential’ phase of growth. In bacterial or yeast system by means of a photocell and appropriate electrical connection the turbidostat can maintain a constant culture density easily by adjusting the flow rate of fresh medium in the culture volume. The rate of flow of fresh medium (F) into the culture divided by the volume of the culture (V) in the vessel which is defined as the dilution rate (D) and is equal to the specific growth rate of the cell (μ) depends only on the medium. Thus,

where tg is the generation time or doubling time of the cells. In ‘chemostat’ however, feed rate and withdrawal rate are held constant at a value less than maximum specific growth rate. Under such conditions the growth rate is regulated by a limiting nutrient concentration. This constitutes a self regulatory and stable steady state.

Although the principle of turbidostat has advantages of three operational allowances in logarithmic phase and non-dependence on limiting nutrient except to the extent that some unknown factor limits the growth of a batch culture but it is associated with many weaknesses namely:

1. It involves apparatus for control that is subject to failure and requires extra investment and maintenance.

2. Turbidity measurements are complicated by the clinging of cells to glass surface in the path of the meter’s light beam.

3. It must operate further from maximal cell population than chemostat, residual nutrient is necessarily higher than the minimum. This makes turbidostat less efficient. For these reasons chemostat principle is more widely used for continuous cultivations/fermentations.

If the cell population were to grow at a rate but without change in the base biomass, a longer time τ would be required for the population to double, which is simply a reciprocal of specific growth rate. Thus

τ = 1μ = tg/0.693 = 1.45tg (2.2)

x is sometimes referred to as ‘birth time’ or that time an organism must exist before dividing when in a population that has a particular growth rate μ.

During growth with ample water and nutrients, the resulting growth rate is an inherent characteristic of the organism, μmax, subject to modification by nutrient balance and culture history. Growth proceeds at a maximal rate that increases with temperature until functions are impaired. The change in μmax with temperature is sometimes expressed as a temperature quotient Q10, the temperature rise that causes the rate to double. Alternatively, the change is expressed as activation energy, Ea, which comes from transition state theory for reversible catalyzed reactions and the assumptions that maximal growth rate is set, as if it were determined by a single rate limiting step. The relationship is

μm = A exp. (Ea /RT) (2.3)

Maximal growth rates are used to characterize the specific ability of populations to increase under favourable conditions and also to identify the growth rate (μm/2) that Michaelis concentration specify. Interpretation of Ea values complicated by multiple interactive phenomena such as sharp change in membrane properties at the transition temperature. However, they remain a convenient way to demonstrate and express the amount of change in rate with temperature.

Cell quota in growth:

In some organisms it was noticed that the amount of limiting nutrient per cell decreased with growth rate as it becomes limiting. These observations led to develop the concept of cell quota. As interspecies and chemical comparisons are impossible without knowledge of cell size, the cell quota Q’ is sometimes expressed as nutrient per gram of cells. Cell quota approaches some minimum value kQ.

μ = μ’m [1 – kQ/Q’] (2.4)

Here is μ’m a constant which is considered to be inflated growth rate μ m. In numerous algal cell systems phosphates, various nitrogen sources, silicon, iron and cobalamine may act as limiting nutrients. Equation (2.4) was found to hold good in these cases. In the special case where all of the substrate collected is laid down and retained as cell material, then considering YG as growth yield.

Q’=1/YG (2.5)

And substrate uptake is given by the widely used relation

q = μQ’X (2.6)

This equation is appropriate for uptake of substrates when exertion of them is negligible. This is not applicable for heterotrophic cells because of the large amount of carbon lost to CO2 and organic products. However, it appears that significant losses occur for other nutrients as well.

For example Chan and Campbell could not account for only 40% of the nitrate-nitrogen taken up as particulate material in studies of freshwater phytoplankton. Leakage of both orthophosphate and organic phosphate has been quantified during phosphate limited continuous cultures of Rhodotorula rubra. The point that a linear decrease in yield with growth rate gives a good fit to equation (2.4) and can easily is demonstrated graphically. Sometimes Q’ is linear rather than hyperbolic with growth rate giving curvature to YG vs μ.

(iii) Genetic Basis:

It has long been observed that a single species of organism can give rise to variation in terms of development of several types of colonies on the same medium. This variation commonly called culture dissociation give rise to variant strains which exhibit considerable differences not only in colony structure but in cellular morphology and physiology as well.

Culture variations are also often observed in repeated subculture. These variations may occur due to genotype or phenotype changes of the culture. Genotype changes are relatively stable alterations of individual genes, of gene assortments, and of the characteristics they control, caused by either automation, sex like processor by lysogenic conversion.

However, when genes merely control the reaction range of a cell, the specific expression of a given characteristics is subject to considerable temporary modification by environmental conditions. Such environment dependent instability in the expression of gene- controlled characteristics is known as phenotype variability and the resulting changes are called phenotype changes.

Certain bacterial cells possess the genetic potential to form a certain pigment produced by the individual cells, however, is influenced by the nutritional conditions and the H+ ion concentration of the environment. Although culture variation may be advantageous in providing the basis for effective selection programme for higher yielding cell, continuing phenotype instability is obviously undesirable.

In the long term, variability in product yield over successive subcultures is potentially a problem and has often been observed in microbial and plant cells. The mechanisms underlying culture instability is still poorly understood. Genetic factors have been invoked, though the evidence mainly derives from numerous investigation of recognizable phenotype abnormalities in cultured cells. Attempts have been made to link gross genomic changes to alteration in secondary metabolite yield in plant cell cultures.