The methods destroying microorganisms from air to supply contamination free air in bioprocess which however are not in practice now include the following:

1. Dry heating by gas fired or electrically heated system

2. Adiabatic-compression

3. Irradiation

The methods which remove particles or microbial load from air stream and of which one of them being industrially/commercially practiced include:

4. Scrubbing

5. Electrostatic precipitation in cyclone separator

6. Sieving

7. Filtration through fibrous beds

8. Filtration through granular beds

Of these methods industrially applicable and fruitful are those of (2), (7) and (8). Filtration through fibrous materials such as glass wool is by far the most common of the three.

Basic Requirements of an Air Sterilizer:

For sterilization of air for industrial fermentation practices the sterilizer must satisfy the following major requirements:

(a) Design of the system should be simple.

(b) The operation cost of the equipment should be cheap.

(c) It should remove or destroy air-borne contaminants to the extent necessary for satisfactory fermentation performance.

(d) In case of repeated steam or chemical vapor sterilization it should be stable.

(e) It should condition the air i.e. it should remove any oil entrained during compression and adjusting the temperature and humidity to a satisfactory range for fermentation.

(f) It should be able to supply sterile air continuously.

Air Sterilization Using Heat:

Many years ago many investigators showed that Bacillus subtilis spores can be sterilized by a passage through an electrically heated furnace. They also concluded that the exit air temperature of 225°C from the furnace was sufficient to kill all the spores of a strain of B. subtilis with an exposure time of 0.4 – 0.6 sees.

Disadvantage:

Very costly method. Also it requires proper cooling of air before sending to fermenter which imparts extra cost.

Sterilization by Air Compressor:

In some fermentation processes the air sterilized by adiabatic compression was used. Stark and Pohler designed a small reciprocating compressor to compress the air to 100 p.s.i for supplying sterile air for seed tank fermenter, for pilot plant studies of the aerobic 2,3 butylene glycol process, for aerobic culture of A. oryzae and for some other purposes.

They demanded reciprocating compressors operated at pressure up to 100 psi. might be preferable for smaller installations but at low pressure turbo-compressors with suitable filters would be more economical for large capacities.

Chain et al. also investigated the sterility of air compressed to 3-4 atm. by a reciprocating piston compressor and reported it to be practically sterile, in agreement with the findings of Stark and Pohler. They used this air in conjunction with glass wool for laboratory scale fermenter and claimed not to have experienced any contamination.

Disadvantage:

Very costly method to be applied to large industrial fermentation.

Air Sterilization by Granular Filters:

Amongst all the granular materials granular carbon has been found to be the best granular filter material for air sterilization. Adsorptive power of charcoal may be the cause of its selection to filtering medium.

A typical carbon filter size for 20,000 gallons fermentor was as follows:

Material of construction = Steel cylinder Diameter = 6′ to 9′

Packed depth = 6′

Granular carbon particle size = 6 to 30 mesh

Usually carbon particles are supported on a bed of graded gravel which rests on a perforated plate. Another perforated plate or screen rests atop the bed.

Pressure drop across this filter = 1 to 5 psi.

Disadvantages:

1. Inlet air temperature cannot be raised above 120°F otherwise carbon may ignite.

2. Although carbon is screened to a coarse mesh size a certain amount of fine carbon dust still adheres to the coarse material. So if steam sterilization under pressure is started spontaneous ignition frequently occurs since the unit behaves like a water gas plant.

Air Sterilization by Fibrous Filters

1. Basic requirements:

At present most commercial air sterilization units are deep beds of glass wool or similar fibrous materials.

The reasons for choosing the fibrous materials are the following:

(a) Their design and operation is extremely simple.

(b) If they are periodically checked and replaced then their reliability is extremely good.

(c) Lower bed diameter and height is required compared to carbon filters for the same sterilization capacity operating at comparable pressure drops.

(d) Glass wool does not pose any hazard.

(e) Collection efficiency is high.

(f) Low pressure drop of air flow through the fibrous filter bed.

2. Filtration effectiveness of fibrous filters:

It was revealed from earlier observations that penetration of microorganisms into a filter was logarithmic in nature. That is, the log ratio of the number of organisms entering a filter (N1) to those leaving (N2) a particular depth of filter, L, was a function of the depth, i.e.

where k = filtration constant and is a function of the following factors:

(a) Air velocity

(b) Filter density

(c) Filter size

(d) Density of organisms to be removed.

The filtration constant, k, is usually expressed in terms of the depth of filter necessary to remove 90% of the entering organism (L90):

This way of representation makes it easier to visualize the filter performance in terms of physical size.

3. Effect of air velocity on filtration:

Various workers performed experiments in terms of L90 and the significances of their experimental data are illustrated in Fig. 4.1.

From this it is seen that the nature of bacterial collection is such that for a particular filter there is an air velocity at which filtration efficiency (N1/N2) is a minimum.

For glass fiber, 16 μ diameter.

When air velocity = 1 fps

then N1/N2 = minimum

Minimal efficiency occurring at inter-medial air velocity is due to the action of different forces in collecting air borne particles at different air velocities.

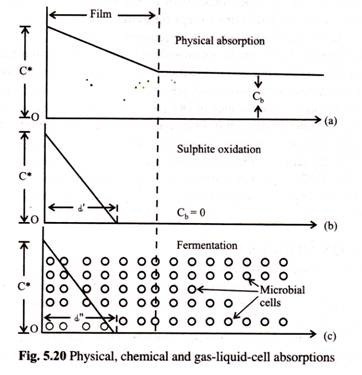

Effect of Low Air Velocity:

At low air velocities particles are exerted by gravitational, diffusional and electrostatic forces and their effect is inversely proportional to the air velocity.

Effect of High Air Velocity:

At high air velocities inertial forces act on the particles. These inertial forces are directly proportional to the air velocity. The nature of inertial effects is such that below a certain critical air velocity collection due to inertial forces is zero. Workers have reported that this air velocity corresponding to inertial impaction is given by

μa = Air viscosity

df = Fiber diameter

pp = Density of air borne organism

dp = Particle diameter

C = A correction factor for deviation from Stoke’s law called slip flow factor.

For collection of unit density, 1μ bacterial particles from air stream, at room temperature and pressure the velocity is equal to

Regardless of air velocity, some collection always occurs due to the fact that air borne particles possess a finite size and will be intercepted by some fiber blocking an air stream along with which a particle moves. Collection must always be greater than that due to interception as it represents the minimum collection physically possible.

In case of collection of phage only diffusion effects are important at reasonable air velocities. So phages are most efficiently collected at low velocities. Collections of phage are not as efficient as bacteria. But, if phage are unusually small i.e. less than 0.05μ or the filter fiber are quite small, less than 2μ in diameter, their efficiency of collection approaches that of bacteria.

Now question may arise whether the filter design is based on bacteria or on phage?

Since little is known about the loading of microorganisms in air stream and since loading can be determined for any plant location, it seems most practical for the present to base filter design on collecting bacteria.

4. Design procedure:

The current thinking on the design of a packed filter for sterilizing air includes the following steps:

(a) Proper assessment of filtration job

(b) Estimation of the filter effectiveness for the particular filter medium

(c) Choice of filter size from cost consideration

Assessment: It involves

(i) Determination or setting of contaminant loading of air,

(ii) Choice of what allowable penetration of these contaminants permit.

(iii) Contaminant loading of air varies depending on various factors. A good sound design figure, when experimental observations are lacking might be 50 microorganisms (m.o) per cubic foot of air.

(iv) The allowable penetration of m.o. must be less than one m.o. during the course of fermentation. A figure involving 1 to 1,000 chance of single m.o. penetrating the filter during particular fermentation should be amply safe.

5. Economic design of fiber filter:

Design should be based on:

(i) Fixed height to diameter ratio of a filter bed i.e. height should be fixed for a given diameter.

(ii) Constant height where diameter is variable.

Basic equation of log penetration law for designing of a fiber filter for air sterilization is as given by equations 4.7 to 4.9

6. Evaluation of bed depth for sterilization:

One way of expressing the efficiency of air filter is

Where

N1 = No. of organisms in entering air

N2 = No. of organisms in leaving air

C = Concentration of microorganisms in incoming air

Q = Vol. flow rate of air in ft/minute

t = Period of operation, minute

p = Allowable chance of penetrating the filter

Combining equations (4.9) and (4.10) one gets

7. Log penetration law and its assessment:

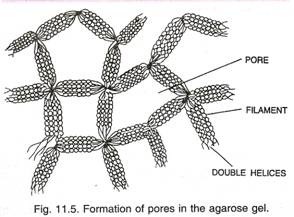

If air borne microbes number, N, passing through a cylindrical bed of fibrous materials are collected uniformly along the bed depth (collection efficiency = ηœ) of single fiber whose vol. fraction in the bed is a and leaving N2 number of microbes in aerosol, the relation between overall collection efficiency, η and bed depth L is logarithmic and is expressed as

In addition the following correlation was used by Aiba based on the empirial correlation presented below

η = η0 (1 + 4.5 α) (4.15)

Where η0 is overall collection efficiency of a single fibre and the value of a being bound in the limit 0<α <0.10.

8. Single fibre efficiency:

In collection of air borne particles/microbes by a single fibre the following mechanisms are presented and supported by experimentation to play major role.

(a) Inertial impaction

(b) Interception

(c) Diffusion

In the relation C is Cunnigham’s factor for slip flow, pp is the density of the particle, dp is its diameter, v0 is the velocity of up-steam air, pa is air viscosity and df is fibre diameter. It has been observed by Longmuir that when Ѱ = 1/16, the value of r)’ is zero at the critical air velocity for this condition to exist is given in equations 4.5 and 4.6.

It shows the relationship of radius of dp with VC with μa as a parameter for a given df. However, if the flowing air borne particles had no mass the flow of air across the fibre would have been closed to streamline. The entrained particles in this streamline air would have been collected by direct contact or interception with the fibres. For such condition Longmuir provides the approximate relation to compute η”0 (the single fibre efficiency due to interception) as

Where R is universal gas constant, N is Avogadro number (6.02 x 10 molecules/g.mol) and λ is mean free path of the particles.

9. Packing of the filter:

The size of the filter may be ascertained using the following relation.

V = L.A

Where V is filter bed volume, L is its height and A is cross sectional area of the bed. The amount of fibre material (W) to be packed in this bed volume is computed by the following equation.

In which W = Weight of the housing fibre material pf=Density of fibre material, lf=Thickness of fibre and f = Allowable free space above and below the packing material.

10. Cost considerations:

An economical fibre filter design as one in which total cost will be minimum. The total cost (C) for the filtration job may be expressed by

In these relations Ce = Cost of equipment/Unit weight, A1 = Annual depreciation allowance, Cf = Cost per unit weight of fibre material, Ar = Annual frequency of packing the filter and Cm = Charge per man-hour. Design should be based on minimum cost. Minimum load corresponding to minimum cost must be taken into consideration for design purpose. The minimum cost is ascertained as shown in the Fig. 4.3.