Read this article to learn about the various methods for sterilization of media and air.

Sterilization of Culture Media and Gases:

For successful fermentation, it is absolutely essential to ensure:

a. Sterility of the media containing the nutrients.

b. Sterility of incoming and outgoing air.

c. Sterility of the bioreactor.

d. Prevention of contamination during fermentation.

A bioreactor can be sterilized by destroying the organisms by heat/chemicals/radiation or sometimes by physical procedures such as filtration.

Sterilization of media and air are discussed below:

1. Sterilization of Culture Media:

The constituents of culture media, water and containers contribute to the contamination by vegetative cells and spores. The media must be free from contamination before use in fermentation. Sterilization of the media is most commonly achieved by applying heat and to a lesser extent by other means (physical methods, chemical treatment, and radiation).

Heat sterilization:

Heat is the most widely used sterilization technique. The quality and quantity of contamination (i.e., the type and load of microorganisms), composition of the media and its pH and size of the suspended particles are the important factors that influence the success of heat sterilization.

In general, vegetative cells are destroyed at lower temperature in a short time (around 60°C in 5-10 minutes). However, destruction of spores requires higher temperature and relatively longer time (around 80°C for 15-20 minutes). Spores of Bacillus stearothermophilus are the most heat resistant. In fact, this organism is exploited for testing the sterility of fermentation equipment.

Physical methods:

The physical methods such as filtration, centrifugation, and adsorption (to ion-exchangers or activated carbon) are in use. Among these, filtration is most widely used. Certain constituents (vitamins, blood components, antibiotics) of culture media are heat labile and therefore, are destroyed by heat sterilization. Such components of the medium are completely dissolved (absolutely essential or else they will be removed along with microorganisms) and then subjected to filter sterilization.

There are a couple of limitations of filtration technique:

1. Application of high pressure in filtration is unsuitable for industries.

2. Some of the media components may be lost form the media during filtration.

Sometimes, a combination of filtration and heat sterilization are applied. For instance, the water used for media preparation is filtered while concentrated nutrient solution is subjected to heat sterilization. The filtered water is now added for appropriate dilution of the media. The chemical methods (by using disinfectants) and radiation procedures (by using UV rays, y rays, X-rays) are not commonly used for media sterilization.

Batch sterilization:

The culture media are subjected to sterilization at 121°C in batch volumes, in the bioreactor. Batch sterilization can be done by injecting the steam into the medium (direct method) or injecting the steam into interior coils (indirect method). For the direct batch sterilization, the steam should be pure, and free from all chemical additives (that usually come from steam manufacturing process).

There are two disadvantages of batch sterilization:

1. Damage to culture media:

Alteration in nutrients, change in pH and discolouration of the culture media are common.

2. High energy consumption:

It takes a few hours (2-4 hrs.) for the entire contents of the bioreactor to attain the requisite temperature (i.e. 120°C). Another 20-60 minutes for the actual process of sterilization, followed by cooling for 1-2 hours. All this process involves wastage of energy, and therefore batch sterilization is quite costly.

Continuous sterilization:

Continuous sterilization is carried out at 140°C for a very short period of time ranging from 30 to 120 seconds. (This is in contrast to the batch fermentation done at 121°C for 20-60 minutes). This is based on the principle that the time required for killing microorganisms is much shorter at higher temperature. Continuous sterilization is carried out by directly injecting the steam or by means of heat exchangers.

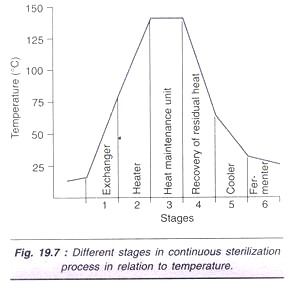

In either case, the temperature is very quickly raised to 140°C, and maintained for 30- 120 seconds. The stages of continuous sterilization process and the corresponding temperatures are depicted in Fig. 19.7. The different stages are— exchanger, heater, heat maintenance unit, recovery of residual heat, cooling and fermenter.

In the continuous sterilization process, 3 types of heat exchangers are used. The first heat exchanger raises temperature to 90-1 20°C within 20-30 seconds. The second exchanger further raises temperature to 140°C and maintains for 30-120 seconds. The third heat exchanger brings down the temperature by cooling in the next 20-30 seconds. The actual time required for sterilization depends on the size of the suspended particles. The bigger is the size, the more is the time required.

The main advantage with continuous sterilization is that about 80-90% of the energy is conserved. The limitation however, is that certain compounds in the medium precipitate (e.g., calcium phosphate, calcium oxalate) due to very high temperature differences that occur in a very short time between sterilization and cooling. The starch-containing culture media becomes viscous in continuous sterilization and therefore is not used.

2. Sterilization of Air:

In general, the industrial fermentations are carried out under vigorous and continuous aeration. For an effective fermentation, the air should be completely sterile, and free from all microorganisms and suspended particles. There is a wide variation in the quantity of suspended particles and microbes in the atmospheric outdoor air.

The microorganisms may range from 10-2,000/m3 while the suspended particles may be 20-100,00/ m3. Among the microorganisms present in the air, the fungal spores (50%) and Gram-negative bacteria (40%) dominate. Air or other gases can be sterilized by filtration, heat, UV radiation and gas scrubbing. Among these, heat and filtration are most commonly used.

(a) Air sterilization by heat:

In the early years, air was passed over electrically heated elements and sterilized. But this is quite expense, hence not in use these days.

(b) Air sterilization by filtration:

Filtration of air is the most commonly used sterilization in fermentation industries.

Depth filters:

When the air is passed through a glass wool containing depth filters the particles are trapped and removed (Fig. 19.8). This filtration technique primarily involves physical effects such as inertia, blocking, gravity, electrostatic attraction and diffusion. Glass wool filters can be subjected to steam sterilization and reused. But there is a limitation in their reuse since glass wool shrinks and solidifies on steam sterilization. In recent years, glass fiber filter cartridges (that do not have the limitations of glass wool filter) are being used.

Membrane cartridge filters:

These are removable pleated membrane filters made up of cellulose ester, nylon or polysulfone. Membrane cartridge filters are smaller in size, simpler for operation and replacement. The most important limitation of air sterilization is that there is no filter that can remove bacteriophages. Bacteriophages are capable of crippling the industrial fermentation. e.g., bacteriophages interfere in the production of glutamic acid by Corynebacterium glutamicum.