The environment of microbial cell processing plays significant role in determining the rates and yields of specific product formation.

The regulatory influence of pH, temperature and pH cycling and temperature profiling indicated improvements in bioprocessing for certain product formation systems.

Two well known examples of such microbial cell processing systems include cellulase enzyme production by Trichoderma reesei strain and propionic acid upstream bioprocessing by Propionibacterium acidiopropionici. In bioconversion of cellulose to ethanol by Clostridium thermocellum using pH and vacuum cycling indicated the merit of the strategy in bioprocessing.

pH Cycling:

1. Mode in cellulase production by T. reesei:

The importance of pH in cellulase production by organisms is known. It was reported that cultivating T. reesei QM9414 in Mandel’s medium containing 1% beech wood cellulose and 0.05% yeast extract for cellulases production showed a fall of pH to 3.0 (initial pH 5.7) in 18 hours. The increase of cellulase production by pH cycling during cultivation of T. reesei has been shown.

The cycling continued for three days and from fourth day pH started rising and was controlled at pH 5.7 to avoid inactivation of enzyme at higher pH due to heavy sporulation. The culture with above strategy showed high oxygen demand (2.1 mM02/g of cells/hr) compared to cells grown without pH cycling (1-1.2 mM02/g. cells/hr).

Natural pH of fermentation medium after sterilization was 5.2 and in the first ten to fifteen hours pH increased to 6.2. At this stage 1 N hydrochloric acid was aseptically added to bring it back to 5.2 and maintained till pH start dropping down.

It started from twenty to twenty five hours of age and reached 3.0 somewhere between forty to forty-five hours of age of cell cultivation. As soon as pH reached 3.0 a peristaltic pump (Watson-Marlow) was actuated to add 2N NaOH at very slow flow rate 0.2 (ml/min) with the help of a circuit diagram for automatic pH cycling (Fig. 6.14).

The addition of NaOH was stopped as soon as pH reached 5.2 and again natural fall to pH 3.0 was awaited. Normally the next cycling needed 18 to 30 hours depending upon physiological conditions of the fungal bio-cells in the fermenter. In cycling control of pH in gold 465 series sterilizable pH electrode with pressure assembly was used. The electrode was pressurized to 1.5 kg/cm2 pressure during sterilization and 0.2 kg/cm2 above residual pressure during the cycle. For fixing the frequency of addition of 2N NaOH in pH cycling, amplifying and controlling Mostech AG regler M7882 was used.

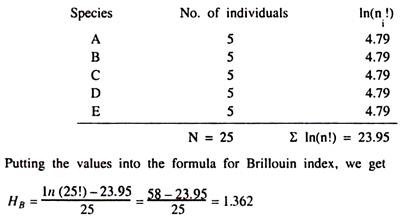

The pH cycling output of the amplifier (0-20 mA) was received in a 741 IC to convert to volt signal and trigger a relay between two control pH point 5.2 and 3.0 to add 2N NaOH. Measured results of cell concentration, cellulase yield, and productivity during cell cultivation and given in Table 6.5 indicated that pH cycling favoured cell growth and increased cellulase yield and productivity. Under pH cycling data obtained with 30 and 40 gl-1 cellulose level (Fig. 6.15 and Table.6.6) were also in concurrence of the same.

2. Analysis in relation to cell growth:

The analysis of results indicated that pH cycling in T. reesei cultivation favours enhanced cellulase production with less cell growth as compared to that controlled pH cultivation. The growth of T. reesei in the pH cycling environment could be expressed by a single species logistic equation containing a periodically oscillating parameter, ф (t), representing the reciprocal of the specific cell yield of T. reesei. From logistic law the growth rate X of T. reesei could be written as

X = (b, X/b2) (b2 – X) (6.76)

in which b, is the specific growth rate, b2 is carrying capacity of cell mass formation. In principle b1 and b2 are functions of time. The physical significance of b1 is as an expression of specific growth rate (p), while b2 represents the maximum level of cell mass formation. Assuming b, represents maximum specific growth rate (pm) and is constant but b2 is a time dependent factor, depending on the substrate uptake rate, which oscillates periodically about a mean value due pH cycling in batch cultivation. So equation 6.76 can be expressed as

b2 (t) = b2 [1+p ф (t)] (6.78)

Here p is a parameter representing the ratio of maximum value of the substrate uptake rate constant (KT) to the specific growth rate (i.e., p = KT/µ), and ф (t) is a periodic function of t with period 0 > 0.

Thus, showing there by that logistic law indicates that in a fluctuating-pH environment, the maximum cell concentration falls below the level attained in a constant pH environment. The amount of decrease (d) in cell concentration is proportional to the square of the amplitude of the oscillating parameter ф (t). Experimental results of the behaviour of T. reesei cell growth and its oscillatory parameter ф (t) at controlled pH 5.2 and with two different pH cycling spans (5.2-3 and 5.2-4) confirmed above theoretical analysis.

Not only that but also the amplitude of the periodic variation of ф (t) decreases as the pH cycling span becomes narrower. Observations with the pH cycling span of 5.2 to 4.6 was also similar. The amplitude of periodic variation of ф (t) as measured was 0.075, 0.05 and 0.025 with the pH cycling spans of 5.2-3, 5.2-4 and 5.2-4.6 respectively.

A plot of square of the amplitude of periodic variation of ф (t) for different pH cycling spans (ω2) against the corresponding decrease is the mean value of the cell concentration (d) showed a proportional relation confirming thereby the validity of equation 6.87. The direct proportionality of d with ω2 (Fig.6.18 and Table 6.7) indicated that a wider span (5.2-3) of pH cycling will increase cellulase production more than a narrow span.

Table 6.7 also shows that an increase of pH cycling limits in T. reesei cell cultivation increases the amplitude of ф(t) and cellulase activity (FPA) but decreases cell growth. Thus, from this analysis it was clear that the maximum cell mass of T. reesei will not necessarily produce the maximum cellulase yield, rather, the proper cycling strategy of pH environmental condition during cell growth yield maximum cellulase enzyme at a considerable cell mass concentration.

3. Bioethanolation:

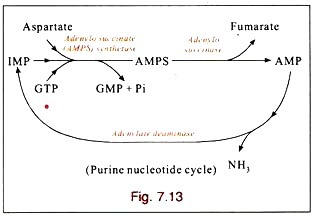

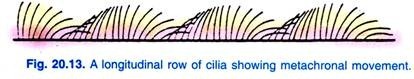

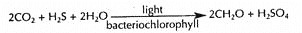

The strategy of pH cycling was also helpful in single step bioethanolation of cellulose by Clostridium thermocellum. This was because CI. thermocellum contained a system of enzymes and each of these enzymes was of different nature having their own pH optima. So pH cycling operation could increase ethanol productivity by periodically favouring the components of enzymes in the system.

The pH of the medium was cycled between 5.2 (initial) to 7.0 by successive addition of 3N NaOH solution. In its reaction sequence this thermophile converts cellulose first into glucose and next through its glucose fermenting enzyme actions glucose is metabolized into multi-products. Among the multi-products ethanol yield is reported to be growth associated and the major one.

Dynamics of this bioconversion in terms of cell growth, substrate conversion and product formation rates showed bio-kinetic information’s of parameters which could reveal product inhibition characteristics. It led to the development of the concept of vacuum cycling process strategy to minimize product inhibition.

4. For enhancement of propionic acid fermentation:

In propionic acid fermentation by Propionibacterium acidipropionici pH was found to influence the lag time, specific growth rate, yield of cells and product formation per gram substrate consumed.

pH could be influencing specific product formation due to the following reasons (Fig 6.19).

(1) pH optima of the enzymes involved in propionic acid pathway to be around 5.

(2) Influence of pH on redox potential which in turn affects the NAD+/NADH ratio. This then determines whether acetic or propionic acid pathway will be followed.

(3) pH influences the C02 tension in the head space which controls the ratio of propionic to acetic acid (Johns, 1951).

(4) pH optima of the enzymes involved in P. acidipropionici pathway for acetic acid production to be around 7.

Ratio of propionic to acetic acid was also greatly influenced by pH. While lower pH gave better ratios of propionic to acetic acid (5:1), the propionic acid productivity was low (0.11 gl-1 h-1) while at pH value above 6 (up to 7.5) lower ratios of propionic acid to acetic acid was obtained (2.5 : 1) but productivity of propionic acid was higher (0.2 gl-1 h-1). Therefore, a pH cycling strategy was adapted which gave higher ratios of propionic acid to acetic acid (5.4) with appreciable productivity of propionic acid (0.22 gl-1 h-1).

Temperature Profiling Mode:

1. Cellulase production:

Four batch cultivation runs at 27, 29, 31, and 33°C were carried out in medium (pH 5.2) containing 30 g/litre cellulose. Cell protein and cellulase activity for each run were measured at different periods. In Fig. 6.20 the plot of cell protein and cllulase activity is shown as a function of cultivation age at different temperatures. For temperature optimization the data in Fig.6.16 were analyzed by logistic law equations 6.88 and 6.89 in the time range indicated.

Equations (6.88) and (6.89) represent cell growth and enzyme production, respectively. In these equations X1 represents the cell concentration, b1, b2, b3, b4, and b5 are parameters of the models, and E is the enzyme elaboration and only cell mass increases with cultivation age.

The parameter b1 is closely related to specific growth rate (1/X1 .dX1/dt) in early stages of cultivation, i.e., when X1 is low and b2 represents maximum cell mass produced. In the region (0 ≤ t ≤ 30 hr) optimization of b1 with respect to temperature will provide maximum growth rate and will give optimum, temperature in this region.

Equation 6.89 describes the behaviour of cellulase production in the region 30 ≤ t ≤ tf hr. The factor b3 describes the fact that the cellulase production in this period is associated with cell mass formation, b4 takes into account the influence of enzyme level present in the reactor on its further synthesis, and b5 incorporates the effect of p on cellulase synthesis.

The term containing b5 is added to account for the fact that cellulase production was enhanced considerably when X1 became equal to b2 and µ becomes zero or slightly negative. The factors b1, b2, b3, b4, and b5 are all functions of temperature. At each temperature the values of b1 and b2 were determined by plotting 1/X1. dX1 /dt vs. X1.

The slope of this plot gives (-b1/b2) and intercept b1. Using equation 6.89 between 30 hr and end of cultivation b3, b4, and b5 were computed from simultaneous equations. The plot of b1, b2, b3, b4, and b5 as a function of temperature is shown in Fig. 6.21.

Negative values of b4 indicate that the presence of cellulase concentration favors production of cellulase. It is because of the fact that cellulase hydrolyzes cellulose to small quantities of soluble substrate (below repression level) which enhances further synthesis of cellulase.

Changes of b5 from positive to negative and then to positive are indicative that cellulase elaboration is favored at zero or slightly negative growth rates. The data of Fig. 6.20 were analyzed following techniques used by Constantinides and Rai to optimize temperature condition at different ages of cultivation. The optimum temperature profile obtained for cellulase production is given in Table 6.8.

2. In penicillin production optimization:

Pontryagin’s continuous maximum principle was used by Constantinides and predicts the optimum temperature profile for penicillin production by Penicillium chrysogenum. It could show that approximately 16% improvement in penicillin yield was possible if the optimum temperature profile were followed during penicillin fermentations as shown in Fig 6.22.

Using the directional integration method in combination with the Fabonacci search in the penicillin model the above optimum temperature profile could be obtained. From their analysis Constantinides and Rai could show that the temperature remained at 27.2°C for the first 56 hours of fermentation, then dropped linearly to 18.7°C and remained constant between 84 to 184 hours. Next 24 hours it returned to initial temperature of profiling 27.2°C. With the help of vector of ad-joint variables their profiling behavior in penicillin production could be explained satisfactorily.

Simultaneous pH Cycling and Temperature Profiling:

1. In cellulase enhancement:

Cellulase production in 30 gf-1 cellulase medium was carried out under pH cycling condition up to 80 hr of cultivation. Beyond 80 hr for pH cycling, 2N NH4OH was used instead of NaOH. During cultivation the temperature was also profiled as in Table 6.9. Cell protein, cellulase activity, and oxygen uptake pattern of the culture under simultaneous pH cycling and temperature profiling are shown in Fig. 6.23.

At an oxygen supply rate of 22mM O2/liter/hr (KLa =124 hr’1) the maximum oxygen demand rate of the culture 5.8 mM O2liter/hr (0.58 mM O2/g cell/hr) was attained during 55-70 hr of cultivation. These results when compared to that of earlier run (Tables 6.5 and 6.6) as shown in Table 6.10 it is seen that simultaneous pH cycling and temperature profiling strategy produced 13% higher cellulase productivity and 16% higher cellulase yield.

Maximum oxygen demand rate was also higher. It appears that by simultaneous and frequent alterations in pH and temperature conditions during cultivations the cellulase-forming system tries to move from one quasi-equilibrium state to another by a path that causes an overshoot in cellulase yield and cellular metabolism of T. reesei for approaching a new equilibrium value. The possibility of such phenomena in other enzyme- forming system is known.

2. Results compared to available reports:

As high as 90 IU/liter/hr cellulase productivity is reported by Ryu et al. from hyper-producing repression-free mutant MCG 77 in the second stage of the two-stage continuous cultivation. To obtain this productivity, the fermentable capacity for cell cultivation stage was 6.8 liter and for cellulase production it was 10 liter.

On equal fermentable capacity basis, however, this productivity becomes 53.0 IU/liter/hr and 16% higher than the 44 IU/liter/productivity obtained in this investigation. The productivity of 44 IU/liter/hr is 1.5 times higher than reported from T. reesei QM 9414 in continuous cultivation. A comparison of high cellulase productivities reported so far is presented in Table 6.10. It shows that appreciable cellulase productivity could be obtained from T. reesei QM 9414 by the present cultivation strategy.

The strategy of pH cycling and temperature profiling in cellulase production from T. reesei has a marked influence on the increase in cellulase synthesis. This technique may increase in cellulase synthesis. This technique may increase cellulase productivity of hyper-producing mutant strain.

3. Effect on RQ behavior of T. reesei:

The strategies of improving both strain of T reesei and technology of processing are vital in relation to cellular physiological behavior and yield of its product. As simultaneous pH cycling and temperature profiling strategy of cellulase production did show appreciable improvement in enzyme yield and productivity its influence on RQ behavior of the cell was also followed.

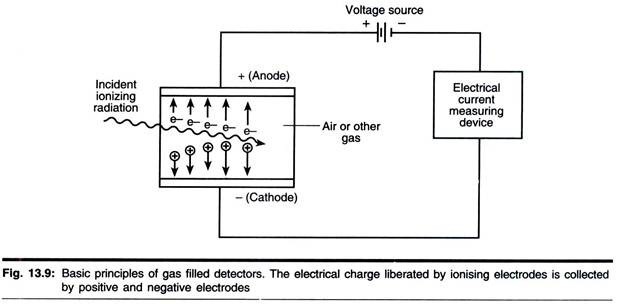

In order to follow RQ behavior during cell cultivation on 3% cellulose medium (C/N 8.5) in automated bioreactor (301, Bioeng AG. Switzerland) exit gas off line estimations of O2 and CO2 were made by Maihak’s Oxygen Analyser and I.R. Analyser. Estimated parameters are shown in Fig. 6.24.

As seen in this figure the highest respiration quotient (RQ) 0.84 was exerted at 64 hours of age. The fermentation has just entered into cellulase production phase and cell growth was passing from exponential phase towards zero specific growth rate phases at this age. At this RQ condition the dissolved oxygen (DO) had dropped below 20% saturation level.

The flow rate of air had to be increased to 61/min from 51/min to maintain DO at 20% level. There was a steady decrease of RQ from 0.84 to 0.575 by the cultivation age of 110 hours. RQ remained at 0.575 till 140 hours and slowly decreased to 0.40 by 180 hours i.e. end of the fermentation cycle.

This behavior showed that the biggest productivity of the enzyme was attained when RQ was constant and maintained at 0.575. The productivity decreased on RQ falling below 0.50. This behavior of RQ in cellulase production is an indication that in fermentation RQ can be used as single parameter for control of complete fermentation process biotechnology.

Simultaneous pH and Vacuum Cycling in Carbohydrate Bioconversion:

In ethanol production by Clostridium thermocellum it was observed that 50 gl-1 substrate (MCCP, Cellulose Product India, Ltd, Ahmedabad, India) was a critical substrate concentration above which severe reduction in ethanol production rate takes place due to substrate inhibition.

Therefore, in vacuum bioconversion of cellulose to ethanol by CI. thermocellum initial substrate level should be within critical limit otherwise productivity decreases to a great extent. Consequently attempts were made to increase the final concentration of the product by vacuum cycling with cellulose fed batch (19 gl-1 to 33 gl-1) bioconversion (60°C, pH 7).

In the fed batch, substrate concentration was maintained nearly at 50 gl level to eliminate the substrate inhibition. The bioconversion lasted for 115 hours but cell lysis began after 90 to 100 hours perhaps due to accumulation of some metabolic inhibitors. The final concentration of ethanol and reducing sugars were 25.57 gl-1 and 19.27 gl-1 respectively. A total of 129 gl-1 of cellulose was fed in 115 hours out of which 14.5 gl-1 remained unconverted hence representing a 88.76% degradation.

It showed that the product yield could be enhanced by vacuum cycling. Further investigations showed that in non-vacuum cultivations increase of substrate level upto 10 g/l increased yield of ethanol above which ethanol yield decreased. However, when the same cultivations were repeated using vacuum cycling (VC) amplitude 220-240 mmHg and frequencies 20-15 hrs the tolerance limit of substrate level in the cultivation system could be increased to 50 g/l.

More than 5 fold increase of substrate level exercised inhibition on ethanol yield in vacuum cycling process (VCP) as well. In NVB system yield of ethanol was only 0.17 g and 0.19g per gram of raw and partially refined bagasse (PRB). By using VCP 0.22 g ethanol per gram PRB was obtained. It was indicative, therefore, that substrate level inhibition was exercised in bioethanolation.

As it is a well known product inhibition system it was necessary to carry out the cultivation experiments by adding initially different concentrations of ethanol in the cellulose medium (2-20 g/l) for checking simultaneous substrate and product inhibition nature. For this µ and γ values were followed as functions of intracellular ethanol concentrations.

It was seen that above 8.7 g/I initial ethanol level in the medium µm and γm decreased to a great extent. Possibility of change in the cell membrane fluidity being available in the literature one could measure the increase in cell membrane pore size in relation to increase in initial ethanol level in the medium based on the following diffusion linked osmotic permeation equation.

In these relations the values of different constants and parameters used are given below:

V1 is the volume of cell C1 and C2 are ethanol concentrations inside and outside the cell respectively. The values of AC,/At were obtained from the slope of the plot of increase in intracellular ethanol concentration as a function of time with initial ethanol concentration as a parameter. It was shown that pore radius obtained from equation 6.90 at 20 g/l initial ethanol level was 1.7 times higher than the radius at 2.0 g/l level of initial ethanol in the medium.

It was therefore indicative that above 8.7 g/l ethanol level in the medium growth was inhibited by ethanol due to diffusion linked osmotic dis-balance in the cells. Since CI. thermocellum contained a system of enzymes and each of these enzymes was of different nature having their own pH optima so simultaneous vacuum and pH cycling operation was carried out for further increase in ethanol productivity.

The pH of the medium was cycled between 5.2 (initial) to 7.0 by successive addition of 3N NaOH solution as shown in Fig. 6.25. The redox potential (Eh) value changed from 0 to 300mv and cycled between -200to -300 mv with the addition of alkali for pH cycling. In this strategy with monoculture system maximum productivity of ethanol obtained was 0.241 g/l/h.

In coculture cultivation of CI. thermocellum with CI. thermosaccarolyticum at 60°C however, further improvement in productivity to 0.55 g/l/h could be seen. It showed that fed batch mode and co\culture processing by simultaneous vacuum and pH cycling is a better approach as compared to product inhibited batch culture using only vacuum cycling with CI. thermocellum alone. However, energy balance of the total process needs to be worked out for in-depth analysis of the access of the process in industry.

Nomenclatures:

P0-osmotic permeability coefficient, Pd-diffusion permeability coefficient, r-pore radius, R-ideal gas law constant, T-operating temperature, ɳ-viscosity, V-partial molal volume, D0 Stokes- Einstein self-diffusion coefficient, K-Boltzmann constant, h-Plank’s constant, X-molecular jump, t-cell wall thickness, H-enthalpy of activation, S-entropy of activation.

Pressure Cycling Strategy in Membrane Bioreactor Operation:

A new operating procedure for the multi-membrane bioreactor eliminating diffusion limitation frequently associated with the operation of a bioreactor has been reported in more recent years. This new mode of operation has been claimed to increase the bioreactor productivity by almost an order of magnitude and also eliminated the need of periodical nutrient additions.

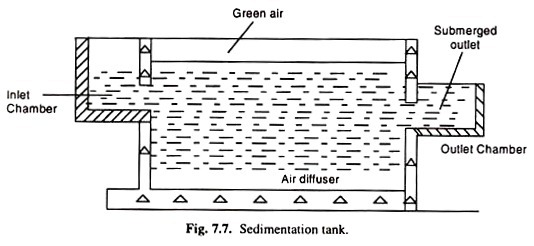

A schematic diagram of this multi-membrane bioreactor and the membrane unit is shown below Fig. 6.26 (A&B) In order to circumvent feedback inhibition and to integrate production and recovery this strategy offering minimization of diffusion limitation has been stated to have advantage.

Anaerobic Pure Culture Bioprocessing:

Anaerobic growth and product formation on glucose in a pure culture of Clostridium thermocellum has been investigated. Cell mass formation on glucose medium of this organism in logistic form is given by