In this article we will discuss about:- 1. Composition of Milk 2. Microflora of Raw Milk 3. Heat Treatment of Milk 4. Milk Products.

Composition of Milk:

Milk is the fluid, excluding colostrum, secreted by mammals for the nourishment of their young. Colostrum is a much more concentrated liquid containing up to 25% total solids, mainly protein, secreted immediately after parturition. A number of animals are used to produce milk for human consumption, although the cow is by far the most important in commercial terms.

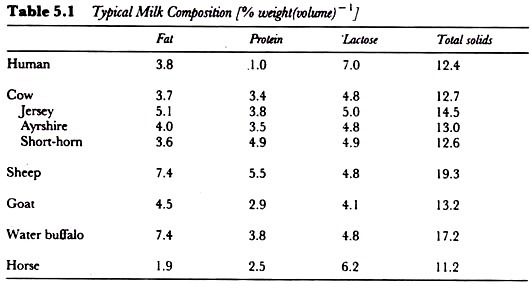

The principal components of milk are water, fat, protein and lactose. The precise composition varies between species so, for example, human milk has lower protein but higher lactose levels than cow’s milk (Table 5.1). Generally the protein content of the milk reflects the growth rate of the young animal – the higher the growth rate, the more protein the milk contains.

There can be considerable compositional difference between breeds of a single species – Jersey and Guernsey milks, for instance, are noted for their higher fat content which is reflected in a richer, creamier taste.

Even within a single breed variations in composition can arise depending on factors such as the stage of lactation, the stage of milking, the intervals between milking, the time of day, the number of previous lactations and the general nutritional state and health of the cow.

A more detailed analysis of cow’s milk is presented in Table 5.2. The lipid content is the most variable feature. It is comprised mainly of C14, C16, C18, and C18:1 fatty acids and is present in fresh milk mainly in the form of fat globules surrounded by a phospholipid rich layer known as the milk fat globule membrane.

Typically these globules have a diameter of about 5µm and the milk contains about 1012 fat globules per litre. If fresh milk is allowed to stand, the fat rises to the surface of the milk to produce a distinct cream line. The tendency for this to happen is reduced if the size of the globules is reduced by passing the milk through a small orifice under pressure; a process known as homogenization.

About 80-85% of the protein in milk is present as caseins. These are milk-specific proteins which are precipitated from milk by decreasing the pH to 4.6. This pH corresponds approximately to their isoelectric point which is relatively low due to the predominance of acidic amino acids and the presence of phosphorus residues in the molecules.

There are five main classes of caseins (see Table 5.2); these aggregate together in association with calcium phosphate in milk to form colloidal particles known as micelles. Milk contains around 1015 casein micelles 1-1 with an average diameter of around 0.2µm.

The stability of the micelle is maintained by the presence of K-casein near or on the surface of the particle. Loss of this stabilizing effect occurs when K-casein is cleaved by chymosin during cheese production and leads to the micelles sticking together to form a coagulum.

The balance of the protein in milk is made up of the whey proteins. These mainly comprise the compact globular proteins β-lacto-globulin and α-lactalbumin but also a number of blood-derived proteins such as serum albumin and immunoglobulin’s. The latter are present at higher levels in colostrum where they presumably confer some resistance to infection in the newborn calf.

Microflora of Raw Milk:

Its high water activity, moderate pH (6.4-6.6) and ample supply of nutrients make milk an excellent medium for microbial growth. This demands high standards of hygiene in its production and processing; a fact recognized in most countries where milk was the first food to be the focus of modern food hygiene legislation.

Milk does possess a number of antimicrobial features, present either to protect the udder from infection or to protect the newborn calf. Generally these are present at too low a concentration in cow’s milk to have a very marked effect on its keeping quality or safety.

In some cases the antimicrobial activity is antagonized by other milk constituents such as the effect of citrate and bicarbonate on lactoferrin activity.

Stimulation of lacto-peroxidase activity through the addition of exogenous hydrogen peroxide has been investigated as a means of preserving raw milk in developing countries where ambient temperatures are high and refrigeration is not often available. In one trial in Africa, use of this technique increased the proportion of samples passing the 10 minute resazurin quality test from 26% to 88%.

Three sources contribute to the micro-organisms found in milk: the udder interior, the teat exterior and its immediate surroundings, and the milking and milk- handling equipment.

Bacteria that get on to the outside of the teat may be able to invade the opening and thence the udder interior. Aseptically taken milk from a healthy cow normally contains low numbers of organisms, typically fewer than 102-103 cfu ml-1, and milk drawn from some quarters may be sterile.

The organisms most commonly isolated are micrococci, streptococci and the diptheroid Corynebacterium bovis. Counts are frequently higher though due to mastitis, an inflammatory disease of the mammary tissue, which is a major cause of economic loss in the dairy industry.

In England and Wales, where it has been estimated to cost the industry around £90 million annually, about 1-2% of cows have a clinical infection at any one time. In the early acute stage of illness the bacterial count in mastitic milk can exceed 108 cfu ml-1 and macroscopic changes are often visible in the milk.

Mastitis is also diagnosed by the presence of high numbers of polymorphonuclear leukocytes which can rise to levels of 107 ml-1 in infected milk.

In addition to acute mastitis, a substantial proportion of the national dairy herd is sub-clinically infected. In these cases there may be no obvious signs of infection yet the causative organism can be present in the milk at about 105 cfu ml-1 and will contribute to an increase in the overall count of bulked milk.

Many organisms can cause mastitis, the most important being Staphylococcus aureus, Escherichia coli, Streptococcus agalactiae, Strep. uberis, Pseudomonas aeruginosa and Coryne- bacterium pyogenes.

The first three of these are all potential human pathogens and a number of other human pathogens such as Salmonella, Listeria monocytogenes, Mycobacterium bovis and Mycobacterium tuberculosis are also occasionally reported.

Infected cows are treated by injection of antibiotics into the udder. Milk from these cows must be withheld from sale for several days following treatment because antibiotic residues can cause problems in sensitive consumers and inhibit starter culture activity in fermented milks.

Attempts to control mastitis by good milking hygiene, use of a disinfectant teat dip after milking and an antibiotic infusion at the end of lactation have helped to reduce streptococcal and staphylococcal infections but have had little success in preventing E. coli mastitis.

The udder exterior and its immediate environment can be contaminated with organisms from the cow’s general environment. This is less of a problem in summer months when cows are allowed to graze in open pasture and is worst when they are housed indoors and under wet conditions. Heavily contaminated teats have been reported to contribute up to 105 cfu ml-1 in the milk.

Contamination from bedding and manure can be a source of human pathogens such as E. coli, Campylobacter, and Salmonella and Bacillus species may be introduced from soil. Clostridia such as C. butyricum and C. tyrobutyricum can get into milk from silage fed to cows and their growth can cause the problem known as late blowing in some cheeses.

A number of measures can be taken to minimize milk contamination from the udder exterior and considerable advice on this topic is available to dairy farmers.

Some of the recommendations made by the Milk Marketing Board, formerly the principal purchaser of milk in England and Wales, included:

1. Providing enough clean bedding and replacing it as necessary;

2. Removing slurry (faeces and urine) from concrete areas at least twice daily;

3. Preventing muddy areas wherever possible;

4. Shaving udders and trimming tails;

5. Washing teats with warm water containing disinfectant and drying individually with paper towels;

6. Keeping the milking parlour floor clean during milking;

7. Thoroughly cleaning teat cups if they fall off during milking and discarding foremilk.

Although such procedures certainly improve the microbiological quality of milk, economic constraints such as increasing size of individual dairy herds and decreased manning levels in milking parlours encouraged their neglect. The introduction of total bacterial count as a basis for payment in 1982 provided an incentive for their more zealous application and led to a marked decline in bacterial count of milk (see below).

Milk-handling equipment such as teat cups, pipework, milk holders and storage tanks, is the principal source of the micro-organisms found in raw milk. As the overall quality of the milk decreases so the proportion of the microflora derived from this source increases.

Milk is a nutritious medium and, if equipment is poorly cleaned, milk residues on surfaces that are frequently left wet will act as a focus for microbial growth which can contaminate subsequent batches of milk.

Occasional neglect of cleaning and sanitizing procedures is usually less serious since, although it may contribute large numbers of micro-organisms to the product, these tend to be fast growing bacteria that are heat sensitive and will be killed by pasteurization.

They are also sensitive to sanitizing practices used and will be eliminated once effective cleaning is resumed. If cleaning is persistently neglected though, the hydrophobic, mineral-rich deposit known as milk-stone can build up on surfaces, particularly heated ones.

This will protect organisms from sanitizers and allow slower growing organisms to develop such as micrococci and enterococci. Many of these are thermoduric and may not be removed by pasteurization.

To encourage farmers to apply the available advice on animal husbandry practices, milking procedures, types and design of equipment and cleaning schedules which contribute to good bacteriological quality milk, the Milk Marketing Board (MMB) in England and Wales introduced in 1982 a system of paying farmers based on the total bacterial count (TBC) of their milk.

Similar schemes have been introduced in a number of countries but details of the MMB’s scheme are presented as Table 5.3. For four months prior to introduction of the scheme, farmers were notified of the TBC count of their milk and in anticipation of its start a dramatic fall in the count was noted (Figure 5.2).

Now more than 76% of the milk produced in England and Wales falls into Band A with a mean count of 1.7 x 103 cfu ml-1.

In most developed countries milk is chilled almost immediately after it issues from the cow and is held at a low temperature thereafter. It is stored in refrigerated holding tanks before being transported by refrigerated lorry to the dairy where it is kept in chill storage tanks until use.

Throughout this time, its temperature remains below 7 °C and the only organisms capable of growing will be psychrotrophs. There are many psychrotrophic species, but those most commonly found in raw milk include Gram-negative rods of the genera Pseudomonas, Acinetobacter, Alcaligenes, Flavobacterium, psychrotrophic coliforms, predominantly Aerobacter spp., and Gram- positive Bacillus spp.

One consequence of the current extensive use of refrigeration and the change to a microflora dominated by psychrotrophs is that traditional tests for the microbiological quality of milk based on the reduction of a redox dye such as methylene blue or resazurin have become obsolete. Psychrotrophs tend to reduce these dyes poorly and the tests are not very sensitive to low numbers of bacteria.

Heat Treatment of Milk:

Proposals for the heat treatment of milk were made as early as 1824, forty years before Pasteur’s work on the thermal destruction of micro-organisms in wine and beer. When milk pasteurization was introduced by the dairy industry around 1890, it was as much to retard souring as to prevent the spread of disease.

This had become an important commercial requirement since large quantities of milk were now being transported by rail into the large cities rather than being produced locally in cramped and insanitary cowhouses.

Milk has long been recognized as an agent in the spread of human disease and within a few years it was appreciated that pasteurization was also providing protection against milk-borne disease. Nowadays it is safety rather than spoilage considerations which determine the minimum legal requirements for pasteurization.

Originally the main health concerns associated with milk were tuberculosis caused by Mycobacterium bovis and Mycobacterium tuberculosis and brucellosis caused by Brucella spp. In some parts of the world milk is still a significant source of these infections but in the UK they have now been effectively eliminated from the national dairy herd by a programme of regular testing and culling of infected animals.

Such programmes must be constantly maintained to be effective and there have been occasional problems. Initiatives such as the culling of badgers, thought to be a reservoir of M. bovis, have been the subject of some controversy and in 1993 there was an outbreak of brucellosis in a Welsh dairy herd, although this was the first recorded for three years.

Enteric pathogens such as Salmonella and Campylobacter are still however prevalent in raw milk and pasteurization remains the most effective measure for their control.

The four types of heat treatment applied to milk are described in Table 5.4. Specification of pasteurization temperatures to the first decimal place is not some arcane feature of thermal processing but is simply a result of conversion from the Fahrenheit scale in which they were originally prescribed.

Low temperature holding (LTH) is a batch process that has been superseded in most countries by continuous high temperature/short time (HTST) pasteurization using a plate heat exchanger. Originally the temperatures prescribed for LTH pasteurization were slightly lower.

They were increased in 1950 in response to the observation that the rickettsia Coxiella metii, the causative agent of Q fever, could survive this original process if present in high numbers.

Spread of this organism through infected milk is a greater problem in the United States than most of Europe, where transmission appears to be mainly through aerosols in the farm environment. More recent fears that Listeria could survive conventional pasteurization treatments appear to be unfounded.

A simple test, the phosphatase test, is applied to determine whether milk has been properly pasteurized. Milk contains the enzyme alkaline phosphatase which is inactivated by the time/temperature combinations applied during pasteurization. To determine whether a milk sample has been satisfactorily pasteurized and is free from contaminating raw milk, a chromogenic substrate is added.

If active phosphatase is still present then it will hydrolyse the substrate producing a colour which can be compared to standards to determine whether the milk is acceptable or not. The same principle is used in the a-amylase test applied to bulk liquid egg.

The microbiological quality of pasteurized milk is now also governed by EC- based regulations which require pasteurized milk to contain less than 1 coliform ml-1, to have a count at 30 °C of less than 3 x 104, and also that, after 5 days storage at 6 °C, its count at 21°C should be less than 105 cfu ml-1.

It is interesting to note that although UHT milk is a low-acid appertized food, the minimum heat process specified falls well short of the botulinum cook required for equivalent canned foods.

It has been claimed that the redox potential in milk is too high to support the growth of Clostridium botulinum but more probable explanations for the fact that botulism has never been associated with this product are a low incidence of C. botulinum spores in milk and the fact that manufacturers employ heat processes well in excess of the minimum legal requirement.

Sterilized milk described in Table 5.4 is a rather specialized product of diminishing importance. In the UK it is defined as a product which is heat processed in-bottle at temperatures above 100 °C for sufficient time for it to pass the turbidity test. This test is based on the principal that the heat process is sufficient to denature whey proteins.

In it, casein is precipitated with ammonium sulfate and filtered off. The filtrate is then heated; if it remains clear the milk is acceptable because the whey proteins have already been denatured and removed with the precipitated casein. Turbidity indicates an inadequate heat process which has left some whey protein un-denatured.

Gram-negative psychrotrophs will not survive pasteurization, although some pseudomonads produce extracellular lipases and proteases which are heat resistant. If enough of these bacteria are present (>105 ml-1), sufficient enzyme can be produced pre-pasteurization to cause rancidity and casein degradation in the processed milk.

Raw milk may also contain a number of organisms known as thermodurics that can survive mild pasteurization treatments. These are generally Gram-positives such as the spore-forming bacteria and members of the genera Micro-bacterium, Micrococcus, Enterococcus and Lactobacillus, but 1-10% of strains of the Gram-negative Alcaligenes tolerans may also survive.

In the main, spoilage of pasteurized milk is due to the growth of psychrotrophic Gram-negative rods such as Pseudomonas, Alcaligenes, Acinetobacter and Psychrobacter, introduced as post-pasteurization contaminants.

Product shelf-life will depend on the number of contaminants introduced, but pasteurized milk produced under conditions of good manufacturing practice should keep for more than 10 days under refrigeration.

Spoilage usually manifests itself as off odours and flavours described as fruity or putrid but visual defects such as clotting due to proteolytic activity can also arise. The souring traditionally associated with milk spoilage and due to the growth of lactic acid bacteria is now rare.

In milk which is subject to very low levels of post-pasteurization contamination, spoilage can result from the growth of thermoduric Bacillus spp. This may be associated with flavour defects but the most studied example is the bitty cream phenomenon produced by the lecithinase activity of Bacillus cereus.

This enzyme hydrolyses the phospholipids associated with the milk fat globule membrane to produce small proteinaceous fat particles which float on the surface of hot drinks and adhere to surfaces of crockery and glasses. Bitty cream is associated mostly with milk that has been subject to temperature abuse, although psychrotrophic Bacillus species are becoming increasingly associated with the spoilage of refrigerated milk.

Milk Products:

Fresh milk is the starting point for a number of other food products, some of which are shown in Figure 5.3. Yoghurt, cheese and other fermented products, dried milk, and the principles behind the production of evaporated milk and UHT milk.

Fat can be concentrated from milk by centrifugal separation to produce a number of different types of cream. These are distinguished primarily by their fat content, which can vary from around 12% for half cream up to 55% in clotted cream, but also by differences in other aspects of their processing such as the heat treatment they receive and whether they are homogenized, whipped or fermented.

After separation the microbial count of the cream fraction is usually higher than that of the skim milk and, despite the fact that some bacteria are removed as slime from the separator, the combined count of skim milk and cream often exceeds that of the original milk.

These observations are a result mainly of physical processes for, although mechanical separators operate at temperatures at which growth can occur (25-30o C), there is limited time for microbial growth during efficient processing.

During separation it is thought that the fat globules rising through the milk act as a moving sieve to which bacteria adhere and become concentrated in the fat layer. The increase in combined count of the two fractions is attributed to the breaking up of bacterial clumps which increases the number of colony forming units, a phenomenon also noticed during the churning of cream to produce butter.

Pasteurization treatments applied to cream are generally in excess of those used with milk because of the protective effect of fat and also because a longer product shelf-life is often necessary. As with milk, the spoilage of cream is due to growth of post-pasteurization contaminants such as pseudomonads and surviving thermodurics such as B. cereus.

Generally lipolytic activity leading to rancidity is a more important feature of spoilage than proteolysis. Butter, made from cream, as the principal example of food preservation by compartmentalization.