In this article we will discuss about the fermentation process of various vegetables by lactic acid.

Sauerkraut and Kimchi:

Most horticultural products can be preserved by a lactic acid fermentation. In the West the most important commercially are cabbage, cucumbers and olives, although smaller amounts of others such as carrots, cauliflower, celery, okra, onions, sweet and hot peppers, and green tomatoes are also fermented.

In Korea fermented vegetables known as kimchi are an almost ubiquitous accompaniment to meals. More than 65 different types of kimchi have been identified on the basis of differences in raw materials and processing. Cabbages and radishes are the main substrates but garlic, peppers, onions and ginger are often also used.

Surveys have shown its importance in the Korean diet, variously reporting kimchi to comprise 12.5% of the total daily food intake or a daily adult consumption of 50-100 g day-1 in summer increasing to 150-200 g day – 1 in winter.

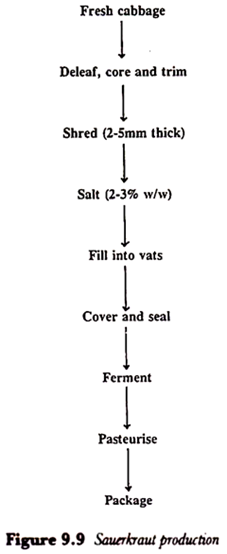

Sauerkraut production is thought to have been brought to Europe from China by the Tartars. Like a number of other traditional fermentations, the commercial process is technologically simple (Figure 9.9), but involves some interesting and complex chemistry and microbiology.

Usually where commercial sauerkraut production is practiced special cabbage cultivars are grown. These tend to have a higher solids content than normal and so minimize production of liquid waste during processing. The outer leaves are removed mechanically and the cabbages de-cored before cutting into shreds about 1 mm thick. The shredded cabbage is then salted and packed into vats for the fermentation stage.

The level of salting is critical to obtaining a satisfactory product, it must be within the range 2-3% w/w and is normally about 2.25%. Too little salt (<2%) and the product softens unacceptably, too much salt (>3%) and the correct microbial sequence is not obtained.

The salt serves a number of purposes:

(i) It extracts moisture from the shredded cabbage by osmosis to form the brine in which the fermentation will take place;

(ii) It helps to inhibit some of the natural microflora of the cabbage such as pseudomonads which would otherwise cause spoilage and helps to select for the lactic acid bacteria;

(iii) It helps maintain the crisp texture of the cabbage by withdrawing water and inhibiting endogenous pectolytic enzymes which cause the product to soften;

(iv) Finally, salt contributes to the flavour of the product.

Traditionally, fermentation vats have been made of wood but nowadays are more often of concrete with a synthetic polymer lining to protect from attack by the acid brine. The tanks are sealed by covering the salted cabbage with plastic sheeting.

They are then filled with brine to press the sheeting on to the cabbage expelling the entrapped air. Although commercial starter cultures for sauerkraut fermentation are available, they are used less often than in other food fermentations.

The time course of a typical sauerkraut fermentation is shown in Figure 9.10 and shows how strongly selective the process is. At the commencement, lactic acid bacteria (LAB) comprise only about 1 % of the total microflora, but many of the nonlactics fail to grow and two days later LAB account for more than 90% of the total microflora.

During this time, they produce sufficient acid to decrease the pH to below 4 further inhibiting the competing microflora. Underlying this overall dominance by LAB is a natural succession of different species which contribute to the characteristic flavour of sauerkraut. The fermentation is initiated by Leuconostoc mesenteroides which is among the less acid- and salt-tolerant LAB but grows fastest during these early stages.

As a hetero-fermenter it produces CO2 which replaces entrapped air and helps establish anaerobic conditions within the product and prevent the oxidation of vitamin C and loss of colour. Since fructose is present as an alternative electron acceptor, it also produces appreciable amounts of acetic (ethanoic) acid from acetyl-CoA which is a major contributor to sauerkraut flavour. Reduction of fructose leads to the accumulation of mannitol.

As the pH drops due to acid production in a weakly buffered medium so the Leuconostoc is inhibited and replaced, first by heterofermentative lactobacilli, and then by more acid-tolerant homo-fermentative lactobacilli such as Lactobacillus plantarum.

Acid accumulation continues in the form of lactic acid although the pH stabilizes somewhere around 3.8 (the pKa of lactic acid). At the end of fermentation which can last from 4-8 weeks the total acidity of the product is 1.7-2.3%, expressed as lactic acid, with a ratio of volatile to non-volatile acid of around 1 to 4.

Defects of sauerkraut arise mostly as a result of yeast and mould growth. These can produce off-odours, loss of acidity, a slimy, softened product as a result of pectolytic activity, or a pink discolouration due to the growth of the yeast Rhodotorula.

In the early stages of fermentation, Leuconostoc mesenteroides fermenting sucrose will preferentially utilize fructose, polymerizing the glucose moieties to produce a dextran slime. This is however transient and is later degraded and utilized by other LAB.

In some brined and fermented vegetables nutrients are not particularly well conserved. These tend to employ high salt levels which draw nutrients and moisture from the product into a high-strength brine which is often discarded and replaced before consumption. This is not the case with sauerkraut which uses a low-salt brine and is not desalted before use.

As a result several vitamins are partially conserved, particularly ascorbic acid, vitamin C. Sauerkraut was used extensively as an antiscorbutic (for the prevention of scurvy) in the Dutch navy in the 18th Century and was also highly regarded in this respect by Captain Cook who ordered servings of a pound per man twice weekly during his voyage of 1772.

Some losses of vitamin C will occur during processing, a 50% reduction was observed in the first five weeks of kimchi fermentation, but nutritional labels on commercial sauerkraut in the United States usually show an ascorbic acid content of 50% of the Recommended Daily Allowance per 100 g serving.

Kimchi is similar to sauerkraut in some respects since cabbage is a common ingredient and the level of salt used is low (<3%). It differs principally in having a shorter fermentation time; the best taste is claimed after 3 days at 20 °C when the acidity is 0.6% and the pH around 4.2.

Consequently Leuconostoc mesenteroides is the principal organism responsible for the fermentation and dominance of Lactobacillus plantarum is regarded as a defect which results in an excessively sour product.

Olives:

Olives are native to the eastern Mediterranean region where they have been cultivated since at least 3000 BC. Today 98% of the world’s hectarage of olives is in the Mediterranean region, most of this going to the manufacture of olive oil.

Substantial quantities (> 600 000 tonnes annually) are also processed into table olives; some are preserved by a canning process similar to other foods but the production of most types includes a period of storage in brine during which a fermentation occurs which contributes to the product’s stability.

Pickled olives in their various forms have a complex taste which often requires considerable application to acquire. In colder climes their consumption has a certain cachet summed up by the 19th Century poet and philosopher Ralph Waldo Emerson who likened them to life at sea: exotic and distasteful.

In the production of Spanish-style green olives, which account for 38% of world production, the unripe fruits are first treated with lye (1.0-2.6% sodium hydroxide solution) to hydrolyse the glucoside oleuropein which imparts a bitter flavour and also inhibits lactic acid bacteria.

This lasts for up to 10 h during which the lye penetrates flesh between a half and three quarters of the way to the stone. The lye is then washed off with water over several h and the fruits placed into a brine.

Initially this contains 5-6% salt but the level is increased in strength during the course of the fermentation up to around 8%. Because some of the natural sugars in the olives will have been removed during the lye treatment and washing, fermentable sugar may be added to the brine.

Complex sequences of bacteria have been reported by different investigators but the most important species appears to be Lactobacillus plantarum. Several other LAB have been reported, including an early phase of growth by Leuconostoc mesenteroides. This, in particular, will depend upon the salt level used since Leuc. mesenteroides is not markedly salt tolerant.

Essentially though, the decreasing pH, increasing acidity and the salt combine to eliminate the natural microflora dominated by Gram-negatives and replace it with one composed of lactic acid bacteria and some yeasts. The fermentation process lasts for several weeks and culminates in a product with a pH of 3.6-4.2 containing around 1% lactic acid.

Starter cultures are available but rarely used at present, the most important measure taken to control the fermentation is to ensure that air is excluded from the fermenting product to prevent the growth of oxidative moulds and yeasts.

The traditional Greek-style product, natural black olives in brine, accounts for 31 % of world production. Processing starts with ripe olives which are placed in a higher strength brine than Spanish-style olives, usually containing up to 10% w/v salt. Fermentation is very slow because the absence of a lye treatment means that oleuropein is still present and that nutrients diffuse slowly through the tough fruit skin.

The microflora is usually dominated by yeasts of which a large number of different species have been isolated and identified including members of the genera Saccharomyces, Hansenula, Candida, Torulopsis, Debaryomyces, Pichia, Kluyveromyces, and Cryptococcus. Lactic acid bacteria may be significant if the salt content is low (<6-7 %) but are generally a minor component.

As a result, there is less acid production than in low-salt vegetable fermentations and the final product generally has a pH of 4.5- 4.8 and a total acidity of 0.1-0.6% expressed as lactic acid. This is not sufficient to confer reasonable stability on die product so the salt content is usually increased to above 10% for storage.

Cucumbers:

Lactic fermentation following pickling in a brine was once the only method for successful preservation of cucumbers. Since the 1940s, ‘fresh pack’ techniques have evolved which do not require a fermentation to confer stability.

The first of these is based on direct acidification with vinegar or acetic acid followed by pasteurization while more recently direct acidification coupled with refrigerated storage has become increasingly popular.

Today in the United States, where more than half a million tonnes of cucumbers are preserved each year, only about 40% are preserved by fermentation, approximately equal volumes are pasteurized and the remainder are preserved by refrigeration. Despite this recent trend fermentation does have a number of advantages over other methods.

(1) Fermented cucumbers have flavour and texture characteristics not possessed by the other products.

(2) Bulk fermentation techniques facilitate quick and easy processing in busy harvest seasons.

(3) Under these conditions, products can be stored in bulk until they are required for further processing, so that year-round working is possible.

(4) Fermentation is more economical with energy than techniques which require pasteurization or an efficient cold chain.

Cucumber fermentations can be divided into essentially two different types: high-salt, or salt stock, and low-salt fermentations. Salt stock cucumbers are fermented in a brine containing 5-8% salt until they are stabilized by conversion of all the fermentable sugars to organic acids and other products. Lb. brevis, Lb. plantarum and Pediococcus pentosaceus are most commonly isolated.

At these levels of salt Leuconostoc mesenteroides does not play the same crucial role as in sauerkraut or kimchi production and at 8% salt it is often not even detected. During the first phase of the fermentation which lasts for 2-3 days the microflora contains a large diversity of bacteria, yeasts and moulds.

The environment is selective for LAB and yeasts which increase while other organisms decrease. The fermentation process is not restricted to the surrounding brine but also occurs within the cucumbers as a result of organisms entering through stomata. Sometimes this can lead to defects in the product known as ‘bloaters’.

Carbon dioxide accumulates within the fruit and is unable to diffuse out, some of this gas production arises from endogenous respiration of the tissues but much is the result of microbial action such as the malo-lactic fermentation and the hetero-fermentation of sugars.

In a controlled fermentation process which has been developed, measures taken to control this problem include the use of strongly homo-fermentative starter cultures containing Lactobacillus plantarum or Pediococcus pentosaceus and intermittent purging of CO2 from the system by bubbling nitrogen through the fermentation.

Genuine dill pickles are fermented in a lower salt brine (3-5%) in the presence of dill and spices. The fermentation resembles sauerkraut production in the sequence of lactic acid bacteria that develops though it is usually conducted at a slightly higher temperature, 20-26°C compared with 18 °C for sauerkraut.

The full curing process-can take up to 8 weeks although active fermentation usually lasts for only 3-4 weeks. The product brine has a pH of 3.2-3.6 and contains 0.7- 1.2% acidity (as lactic acid) but will include appreciable amounts of acetic (ethanoic) acid.