In this article we will discuss about the manufacture of soy sauce. Learn about: 1.Production Process and 2. Flow Chart for manufacture of soy sauce.

Of the many Oriental fermented products, soy sauce is the one most widely consumed and the only one that has become well known in the cookery of Western countries. Soy sauce is a dark brown liquid with a salty taste and a distinct pleasant aroma suggestive of meat extracts. It is a seasoning agent used as substitute for salt in preparation of food as well as a table condiment.

It enhances the flavor and adds to the color of meats, sea-foods, vegetables, and other foods. The product is known as chiang-yu in China; kecap in Indonesia; shoyu in Japan; kanjang in Korea; toyo in the Philippines; and see-iew in Thailand. In the Western world, the name soy sauce has been adopted.

Soy sauce is made by fermentation of a combination of soybeans and cereal, usually wheat, and salt. Some historical accounts seem to indicate that the fermentation of soy sauce may have been patterned after a fermented fish product used along the coast of Southeast Asia.

The fermentation was said to have originated in China during the Chou dynasty (1121- 220 B.C.), and the Chinese made it in ancient times as a household industry. Today, soy sauce fermentation is one of the most advanced, sophisticated, and studied food industries. Nevertheless, in some parts of the Orient, soy sauce fermentation has remained as a family art.

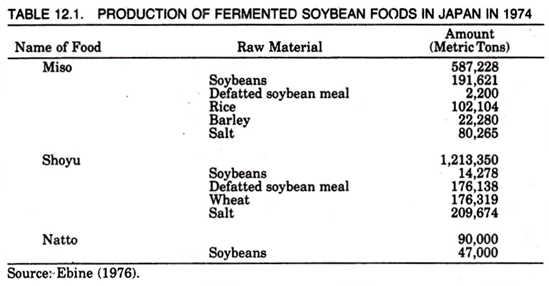

According to Ebine (1976), 253,000 MT of whole soybeans and 178,000 MT of defatted soybean meal were used in Japan in 1974 to produce shoyu, miso, and natto. His data are summarized in Table 12.1. The total production of shoyu in Japan exceeds 1 million kl a year. There are more than 4000 shoyu producers in Japan; however, the biggest 4 or 5 companies produce about 50% of the total production.

The annual per capita consumption is estimated at about 10.2 liters. Similar information is not available from other nations of the Orient, but the per capita consumption figure may well apply to other Oriental populations, especially to the Chinese. There seems to be little doubt that Japan leads the soy sauce industry in the world. Japan not only has the largest fermentation plant but also employs the most advance technology developed through comprehensive research on all aspects of soy sauce fermentation.

In addition to the fermentation process, soy sauce is also made by a chemical method in which acid hydrolyzes the proteins and carbohydrates. Acid hydrolysis usually results in a more complete breakdown of the substrates than enzyme hydrolysis; however, acid hydrolysis cannot perform many of the other specific reactions or inter-reactions of hydrolyzed products as carried out by the multiple enzyme systems produced by molds, yeasts, and bacteria. Chemical soy sauce, therefore, does not possess the flavor and odor of fermented soy sauce.

The technology of soy sauce fermentation, as well as of other traditional fermentations, was formerly a closely guarded family art. Now, the major steps are no longer a secret, but the important fine points are still confidential information. Many improvements have been made since the early development of the fermentation, but the basic method of manufacture is almost unchanged and is illustrated in Fig. 12.1. In preparation for fermentation, soybeans are usually soaked overnight, drained, and steamed for several hours. The effect of cooking conditions on the enzymatic digestion of soybean proteins has been studied; cooking at higher temperatures and for shorter times seems to be the current trend.

Tateno and Umeda (1955) and the Noda Soy Sauce Co. (1955) claimed that the soybean protein was best utilized when the beans were soaked in water for 10-12 hr at room temperature and then autoclaved at 69-90 kPa (10-13 psi) for about 1 hr. A batch-type cooker was then developed so that the temperature could be raised rapidly to over 120°C and lowered quickly immediately after cooking.

Because of economic advantages, over 90% of shoyu in Japan is now made from defatted meal or flakes. According to Umeda et al. (1969), defatted soybean products first are moistened by spraying with water amounting to about 130% of soybean weight and then are steamed at 90 kPa (13 psi) for 45 min.

The cooked soybeans are mixed with wheat that has been roasted and cracked or coarsely ground. The proportion of soybeans to wheat may vary from one manufacturer to another. The best soy sauce is generally believed to be made from a soybean to wheat ratio of 50:50 by weight or 52:48 by volume. The use of wheat decreases the total nitrogen content of soy sauce, but it contributes aroma and flavor.

The soybean-wheat mixture is next inoculated with a starter which is known as tane koji in Japan and as chung chu (seed mold) in China. A good starter culture must give characteristic aroma and flavor to the soy sauce, have high proteolytic and amylolytic activities, and must be easy to culture.

Molds used in soy sauce fermentation have been extensively investigated. The commercial starter or tane koji is made under strictly controlled conditions with tested strains of Aspergillus oryzae and A. soyae, such as A. oryzae NRRL 1988 and 1989. The pure cultures are grown separately on cooked rice for 3—5 days at 30°C until the rice is covered with spores, which are then harvested.

Tane koji is usually a mixture of pure spores consisting of several strains in appropriate proportions. A detailed account of the preparation of tane koji—whether for shoyu or other fermentation—can be found, in a review of Shibasaki and Hesseltine (1962). The Japanese manufacturers recommend inoculating the soybean-wheat mixture with tane koji at a rate of 0.1 to 0.2%.

The inoculated mixture is distributed in shallow wooden boxes to about 5 cm in depth and then incubated at 30°C. After 24 hr of incubation, the mixture is covered with a thin white growth of mold. As mold growth continues, the temperature of the mixture could rise above room temperature to 40°C or higher.

Therefore, the mixture should be turned or stirred periodically to maintain uniform temperature, moisture, and aeration. The mixture should also be free of lumps to minimize bacterial propagation. As the incubation time increases, the molds continue to grow and their growth turns yellow and dark green.

The moisture of the mixture gradually decreases. After about 72 hr of incubation, the molded mixture, which is called shoyu koji in Japan and chiang chu in China, is ready for brine fermentation. In recent years, automatic koji-making processes have been developed to replace the traditional way of making koji, which involved wooden trays and hand mixing.

The new equipment includes automatic inoculator, automatic mixer, large perforated shallow vats in closed chambers equipped with forced filtered air devices, temperature controls, and mechanical devices for turning the substrates during incubation.

Shoyu koji of superior quality has a dark green color, pleasant aroma, sweet but bitter taste and, most important of all, high activities of proteases and amylases. The relationship between enzyme yield and culturing conditions varies with the organisms. A. oryzae and A. soyae produce greater amounts of proteases at temperatures lower than their optimum growth temperature.

Similar findings with other fungi were reported by Wang et al. (1974). The effect of temperature on enzyme production observed in these studies emphasizes the importance of a common practice in koji making, i.e., frequent turning of the growth mass or use of thin layers of solid substrates. Otherwise, the heating which results from active growth will increase incubation temperature and affect enzyme production. Harada (1951) found it necessary to keep moisture content of koji at 27 to 37% in order to maintain high enzyme activity.

So moisture and temperature are the two more important factors in making koji of superior quality. Current industry practice is to increase moisture content of the soybean-wheat mixture and to lower incubation temperature.

The second step in preparation of soy sauce is brine fermentation. Traditionally, the shoyu koji is transferred to a deep vessel in which an equal volume of salt solution (17 -19%) is added to make a mash or moromi as it is called in Japan, but recently the volume of salt solution has been increased to 1.1 to 1.2 times that of the koji.

It was found that moromi made with a ratio of salt solution to koji greater than one had a better utilization of the total nitrogen of the raw material; also the lower the concentration of salt in the salt solution the better the utilization of nitrogen. On the other hand, when the concentration of the salt solution is less than 16%, putrefaction may occur.

Since koji making is not done under aseptic conditions, one would expect the presence of yeasts and bacteria in the moromi. However, pure cultures of yeasts and bacteria are sometimes added to the mash to accelerate the fermentation and to improve the flavor of the final product. Strains of Saccharomyces rouxii, Torulopsis yeasts, and Pediococcus soyae were found to be important flavor producers.

Representative strains maintained in the Agricultural Research Culture Collection (NRRL) have been designated as S. rouxii NRRL Y-6681, T. etchellisii NRRL Y-7583, T. versatilis NRRL Y-7584, and P. halophilus NRRL B-4243 and NRRL B-4244. The initial pH 6.5-7.0 of the mash gradually decreases as the lactic acid fermentation advances, and at a pH of around 5.5, yeast fermentation takes place.

The moromi is stirred occasionally during the early stage of the process to provide enough aeration for good growth of yeast, to prevent the growth of undesirable anaerobic microorganisms, to maintain uniform temperature, and to facilitate the removal of carbon dioxide.

However, too much stirring hinders the fermentation. The change of temperature is said to be important for the normal progress of fermentation. Therefore, shoyu fermentation in Japan usually starts in April and takes a year to complete. In general, low temperature fermentation gives better results; because the rate of enzyme inactivation is slow, the enzymes remain active longer.

Watanabe (1969) indicated that good quality shoyu can be obtained by 6 month fermentation when the temperature of moromi is controlled as follows- starting at 15°C for 1 month, followed by 28°C for 4 months, and finishing the fermentation at 15°C for 1 month.

The matured mash is then pressed and the liquid is pasteurized at 70°- 80°C to stop the microbial and enzymatic reactions, filtered to remove precipitates, and bottled for market. In Japan, either benzoic acid or butyl- p-hydroxybenzoate is added as a preservative.

Average composition of soy sauce made from whole soybeans and defatted soybean meal by 11 factories in Japan is given in Table 12.2. A good soy sauce has a salt content of about 18%. Its pH is between 4.6 and 4.8; below that the product is considered too acid, suggesting that acid has been produced by undesirable bacteria.

It is also generally recognized in Japan that the quality and price of shoyu are

determined by nitrogen yield, total soluble nitrogen, and the ratio of amino nitrogen to total soluble nitrogen. The nitrogen yield is the percentage of nitrogen of raw material converted to soluble nitrogen, which shows the efficiency of enzymic conversion.

The total soluble nitrogen is a measure of the concentration of nitrogenous material in the shoyu and indicates a standard of quality. A ratio of greater than 50% of amino nitrogen to total soluble nitrogen is also evidence of quality. These results can be affected by many factors such as raw materials, steaming conditions, tane koji, koji making, and brine fermentation.

Technology to improve these values is constantly being sought. During the last 20-30 years, a shorter cooking time at higher temperatures has been adopted. Koji-making technology has been improved so as to increase enzymatic activity. New strains of koji molds, yeasts, and bacteria have been developed by induced mutations or by diploid formation.

Temperatures for moromi fermentation have been controlled. As a result of these improvements, nitrogen recovery has increased from 60% in 1945 to about 90% in 1975, the fermentation period has been reduced significantly, and flavor has been greatly improved.

The chemical changes in the production of shoyu and in its flavor are complicated. Yokotsuka (1960) has written a complete review on these changes. He states that of the total nitrogen, about 40-30% is amino acids, 40-50% peptides and peptones, 10-15% ammonia, and less than 1% protein.

Seventeen common amino acids are present, with glutamic acid and its salts being the principal flavoring constituents. The organic bases, believed to be hydrolyzed products of nucleic acids, are adenine, hypoxanthine, xanthine, guanine, cytosine, and uracil.

Sugars present are glucose, arabinose, xylose, maltose, and galactose; also 2 sugar alcohols, glyercol and mannitol. Organic acids reported in shoyu are lactic, succinic, acetic, and pyroglutamic. The color of soy sauce is generally recognized to be the result of a nonenzymatic browning reaction.

More than 100 compounds have been reported as flavor components of soy sauce; the compounds that decisively characterize soy sauce, however, remain unknown. The guaiacyl compounds seem to have an important effect upon the overall flavor of Japanese shoyu.