Here is a list of eight major oriental fermented foods. The oriental fermented foods are:- 1. Ontjom 2. Hamanatto 3. Natto 4. Idli 5. Ang-Kak 6. Fermented Fish Products 7. Miso and 8. Sufu. Also learn about their fermentation process.

Oriental Fermented Food # 1. Ontjom:

Ontjom, or oncom, a product closely related to tempeh, is another traditional Indonesian food, especially popular in West Java. Like tempeh, ontjom is a solid cake-like product and is commonly served deep fat-fried or cooked in other native dishes.

Peanut press cake is generally used as substrate in ontjom fermentation, although coconut press cake, cassava press cake, and residues from making soybean milk and tofu are sometimes used wholly or in part, either to improve the texture or to reduce the cost of the product. The fermentation is carried out by strains of Neurospora or Rhizopus; Neurospora fermentation results in a pink or orange cake and Rhizopus in a cake of ash-grey color.

The preparation of ontjom in Indonesia as described by various investigators is summarized in Fig. 12.4. The peanut press cakes are broken into pieces and soaked in water for 24 hr or until soft.

They are washed, drained, and gently pressed to remove the excess water. Some fatty materials that float over the surface during soaking should also be removed. The soaked peanut press cakes are mixed thoroughly with cassava press cakes which have been crumbled and screened through a coarse sieve.

The resulting mixture is steamed for 1 to 1-1/2 hr and then transferred to a mold to form a flat cake about 2-3 cm in thickness. After cooling, the cakes are inoculated with powdered ontjom from an earlier preparation and placed in bamboo trays, which are then kept at 25° – 30°C for 1 – 2 days.

The cakes are actually exposed to the air during fermentation, even though some manufacturers cover the cake with banana leaves. This practice favors sporulation, so that the fermented cake is covered with the orange spores of Neurospora to form an orange cake, or covered with the black spores of Rhizopus to form an ash-grey cake. In tempeh fermentation sporulation is undesirable and is largely prevented by restricting aeration.

Typical ontjom cultures maintained in the AR Culture Collection are designated as N. sitophila NRRL 2884 and R. oligosporus NRRL 2710. However, Ho (1976) recently made an investigation of the ontjom culture and reclassified the Neurospora as AT. intermedia based on meiotic sterility.

Van Veen and Graham (1968) used pure cultures of Neurospora isolated from ontjom samples from Indonesia to study the ontjom fermentation. They found that the mold grew well on substrate with a pH lower than 6.0 and that its growth was stimulated by the addition of tapioca. Incubation temperatures of 25° or 30°C were equally suitable for fermentation; higher temperatures, however, were not advantageous.

Also, the quality of the final product was greatly affected by the heat treatment of the substrate. They concluded that extraction of the peanut press cake with hot water, addition of 1% tapioca followed by pasteurization (30 min at 65°C), and adjustment of pH to 4.5 would produce the best product judging from mold growth, sporulation, color, and flavor development.

According to Winarno (1979), fresh ontjom has a moisture content of 57%; protein, 13%; fat, 6%; and carbohydrates, 22%. As in the tempeh, the proximate composition of ontjom resembles that of the unfermented substrate, but its constituents are probably hydrolyzed in various degrees by the enzymes produced by the mold.

The protein efficiency ratio of the peanut protein as determined by the rat assay is not changed by the fermentation, and there is also no effect on the apparent digestibility after fermentation. Never the less, rats receiving the ontjom diet had a higher food intake than the rats receiving the diet containing unfermented peanut. The increased food intake resulted in a concurrent increase in weight gain. Therefore, the fermentation process may have increased the palatability of the peanut press cake.

Oriental Fermented Food # 2. Hamanatto:

Hamanatto is a Japanese name for a salty fermented whole-soybean product that is quite popular in many Oriental countries. The product is known as “tou-shih” in China; “tao-si” in the Philippines; and “tao-tjo” in the East Indies. It has a pleasant flavor, resembling that of a soy sauce, and is nearly black. The fermented beans are used as a side dish to be consumed with bland foods, such as rice gruel, or they can be cooked with vegetables, meats, and sea-foods as a flavoring agent.

Preparation methods may vary from country to country, but the essential features are similar. Soybeans are soaked and steamed until soft, drained, cooled, mixed with parched wheat flour, and then inoculated with Aspergillus oryzae. After incubation for 1-2 days, the beans, which are now covered with green mold, are dried in the sun to about 10-12% moisture. The dry beans are packed in a container with the desired amount of salt, spices, wine, sugar, and water, tightly covered, and aged for several weeks or months.

After fermentation, the beans are dried again. The composition of the brine solution varies with each country; thus, the final product differs somewhat in taste and appearance. Japanese hamanatto is rather soft, having high moisture content. Chinese tou-shih is not as soft and has lower moisture than that of hamanatto. Tao-tjo tends to have a sweet taste because sugar is often added to the brine.

Investigations on the hamanatto fermentation are inadequate; thus, methods of producing the product have not been modernized. Recently, Kon and Ito (1975) found that the main microorganisms considered responsible for the hamanatto are strains of A. oryzae, Streptococcus, and Pediococcus. The A. oryzae strain is dark olive-green and produces strong proteolytic, but not amylolytic, activity.

Oriental Fermented Food # 3. Natto:

In Oriental soybean fermentations, molds usually dominate, but the natto fermentation is an exception in which bacteria predominate. The bacterium Bacillus natto, identified as B. subtilis, is the organism responsible for this fermentation. Thus, natto possesses the characteristic odor and persistent musty flavor of this organism, and is also covered with the viscous, sticky polymers that this organism produces.

Perhaps because of its characteristic odor, flavor, and slimy appearance, natto, even though it is, well known in Japan, especially in Northern Japan, is not so popular or so widely consumed as compared with other fermented soybean foods.

However, there seems to be an upswing in consumption; the production of natto in Japan was 30,000 MT in 1959 and 90,000 MT in 1974. The yearly per capita consumption in 1974 was about 760 g as reported by Ebine (1976). Other than Japan, natto is also produced and consumed in Korea.

In Japan, natto is seasoned with soy sauce, salt, or sometimes mustard, and served with rice. Making natto is a simple operation and can be easily done at home. After the beans are soaked, they are boiled, drained, cooled, wrapped in rice straw, and kept in a warm place for 1-2 days.

The quality of the product is then ascertained by the stickiness of the beans and their flavor. Rice straw is credited not only with supplying the fermenting organism, but also with providing the aroma of straw, which many consumers are fond of, and with absorbing the unpleasant odor of ammonia from natto.

In industrial practice, the beans are first soaked in water for 16-20 hr at 15°C or 12-16 hr at 20°C, and then steamed under pressure for 30-40 min. The cooked beans are inoculated with natto starter, which is B. natto grown in peptone-glucose media at 37°C for 24 hr. The inoculated beans are wrapped in a paper-thin sheet of pine wood or packed in plastic packages weighing about 80-120 g. The fermentation lasts for 15-20 hr at 40°-43°C in the package in which they are sold.

Many papers have been published concerning the microorganisms in natto fermentation; however, it is now well established that bacilli are the most important ones. In 1960, Sakurai reconfirmed that B. natto is an aerobic, Gram-positive rod, and classified it as a related strain of B. subtilis. There are two types of B. natto in the laboratory of the Food Research Institute, Ministry of Agriculture and Forestry, Tokyo, Japan.

One has optimum temperature from 30° to 45°C and the other, from 35° to 45°C. He recommended the culture known as B. natto SB-3010, with an optimum temperature of 30°-45°C, as the one more suitable for making natto. In our AR Culture Collection, we have several strains of B. subtilis suitable for natto fermentation, namely NRRL B-3383, B-3384, B-3385, B-3386, B-3387, and B-4008.

Recently, Ohta et al. (1976) investigated the effects of fermentation time on the organoleptic quality of natto; they found that natto made with 8 hr fermentation had the highest overall scores, whereas natto made with the traditional 16 hr fermentation received a poor rating. In general, when the ammonium production exceeds a level of 1%, the product becomes obnoxious. Perhaps short-period fermentation would result in a product of mild flavor that would gain acceptance from more people.

Natto has a short shelf life, partly because it has moisture content of 60% and partly because it is usually prepared in small- scale plants with poor quality control. Cold storage has been used to extend its shelf life.

There are many reports concerning the changes which occur during natto fermentation. Hayashi (1959) made one of the most comprehensive studies. His data indicated that there was no change in fat and fiber contents of soybeans during a 24 hr period of fermentation, but that carbohydrate almost totally disappeared. A great increase in water-soluble nitrogen and ammonia nitrogen was noted during fermentation as well as during storage.

The amino acid composition remained the same. Boiling markedly decreased the thiamin level of soybeans; but fermentation by B. natto enhanced the thiamin content of natto to approximately the same level as soybeans. Riboflavin in natto greatly exceeded that in soybeans.

Vitamin B12 in natto was found by Sano (1961) to be higher than in soybeans. Conflicting results on the nutritive value of natto have been published by several investigators. They disagreed on the nutritive value of natto protein as being superior to that of boiled soybeans.

But they agreed that rats fed a diet containing natto and rice grew as well as rats receiving a complete laboratory diet; whereas, rats fed a diet of boiled soybeans and rice did not grow as well as the controls. However, Hayashi found that addition of thiamin to the diet of boiled soybeans and rice corrected the deficiency; the growth of rats receiving a thiamin-enriched diet of boiled soybeans and rice was comparable to that of rats fed natto and rice.

Oriental Fermented Food # 4. Idli:

A great variety of fermented foods is consumed daily in India and her neighboring countries, but idli is the only one that has been studied in much detail.

Idli is a breakfast dish in most parts of India, especially popular in southern India. It is usually prepared by steaming a fermented batter consisting of rice and black gram (Phaseolus mungo)—a legume, arid is served like pancakes with butter and honey, or with jams and other sauces. The steamed pancakes are soft and spongy and have a desirable sour taste and flavor.

Like most of the fermented foods consumed in the Asiatic countries, idli is made by natural fermentation. Generally decorticated black gram known as black gram dahl and rice are soaked separately in water for 3-10 hr before grinding into a paste. Parboiled rice semolina is frequently used, but dry black gram flour is not suitable. The two pastes are mixed with some salt and enough water to make a batter of desirable consistency and then allowed to ferment at 25°-30°C for 14 to 16 hr.

While the proportions of rice to black gram have varied from 4:1 to 1:4 in various studies, the best result was obtained when the proportion of rice to black gram was 1:2. When the black gram was less than 25%, the steamed idli was hard and organoleptically unacceptable; when it was more than 50%, the product was too sticky to be acceptable.

The amount of water required to prepare batters of desirable and uniform consistency depends upon the proportions of rice to black gram dahl and varies from 1.5 to 2.2 times the dry weight of the ingredients.

Both rice and black gram act as substrates as well as providing microorganisms, but the major component contributing to the fermentation appears to be the black gram. Presoaking was found to be an important step of the fermentation; it provides extra fermentation time and microorganisms essential for the fermentation.

Mukheijee et al. (1965) made a thorough study of the microorganisms responsible for the leavening action of idli. They first washed the black gram with tap water and then distilled water, presumably to remove some of the surface microorganisms. The washed beans were soaked for 8 hr in distilled water, then ground and mixed with rice semolina and salt to prepare the batter.

The batter was then allowed to ferment at 30°C. Soaking water, as well as fermenting batter, was sampled at 4 hr intervals for plate count of microorganisms by using a tryptone, glucose, and yeast extract broth. The microorganisms responsible for the fermentation were then isolated and identified. The authors found that the rate of growth of microbial populations was exceedingly high during soaking and the early stage of fermentation.

Of these isolates, about 95% were Leuconostoc mesenteroides. In the later stages of fermentation, growth of Streptococcus faecalis and, still later, of Pediococcus cerevisiae became significant. Thus, the authors found that the microorganism responsible for souring, as well as for gas production, was L. mesenteroides.

Rajalakshmi and Vanaja (1967) also identified the microorganisms responsible for idli fermentation as L. mesenteroides which was present in black gram. However, Batra and Millner (1974) consistently isolated Torulopsis Candida (Saito) Lodder and Tricho- sporon pullulans (Lindner) Diddens and Lodder from samples of idli batter collected from the major center of production—Madras, India.

They prepared idli batter with these two yeasts, either singly or in combination, and found that idli having the characteristic consistency, appearance, and flavor can only be made by the combined action of the two yeasts; both of the yeasts imparted the characteristic acidity, and T. Candida also produced gas. Desikachar et al. (1960) have shown that both yeasts and bacteria participate in the idli fermentation. However, acid and gas production have been found to be mostly dependent on the bacterial growth.

Some investigators have added yeasts and buttermilk as inocula, but Steinkraus et al. (1967) found that idli prepared with added dry yeast and/or sour buttermilk inoculum was similar to that prepared without inocula. However, they experienced no fermentation failures with added inocula, while occasional failures were encountered without the inocula.

A variation often used in India is to mix the ingredients with water at 80°C. Steinkraus et al. (1967) reported that the normal bacterial flora was markedly decreased from 15,000 to about 600/g, even if the batter was maintained at 80°C for only a matter of minutes. This practice generally resulted in a slower fermentation and an idli with an altered aroma and flavor.

The two more significant changes during idli fermentation are leavening and acidification of the batter; these have been used as the criteria for judging the progress of fermentation. During fermentation, the volume of idli batter has been reported to increase, ranging from 1.6 to 3.1 times its original volume. The pH falls from 6.0 to 4.3-5.3, and acidity increases from 3.2 to 19.0 ml of 0.1 N lactic acid per 25 g idli batter.

Soluble solids generally showed a slight increase during fermentation, whereas soluble nitrogen showed a decrease. This is a contrast to some fungal fermentation, such as tempeh, which usually shows considerable increases both in soluble solids and nitrogen during fermentation.

Idli is generally considered a nourishing and easily digestible food. However, results obtained from the growth and nitrogen balance experiments with rats do not show that the nutritive value and digestibility of proteins of the rice and black gram mixture are improved by the fermentation process.

On the other hand, Radhakrishna Rao (1961) disclosed that feeding of fermented idli reduces the liver fat content of rats fed a high fat and low protein diet. The results were further substantiated by his findings that there was an increase in choline, methionine, and folic acid content of the rice and black gram mixture after fermentation.

Rajalakshmi and Vanaja (1967) also found idli superior to an unfermented product. Varied results on the effect of fermentation on methionine and cystine content of the substrate mixture, showing an increase in some and a decrease in others, were observed by Steinkraus et al. (1967).

They found an apparent increase in both methionine and cystine in idli prepared from a 1:1 proportion of rice to black gram. Obviously, more research is needed on the synthesis of methionine in idli fermentation which would be a most valuable contribution to Oriental fermented foods, because these foods are usually made from plant materials that are generally low in methionine.

Oriental Fermented Food # 5. Ang-Kak:

Chinese red rice, or ang-kak, originated in China; it is a product made by fermenting rice with strains of Monascus purpureus. Only those strains that produce a dark red growth throughout the rice kernels, at low enough moisture levels to allow the individual grains to remain separate from one another, are suitable for the fermentation. Because of its color, ang-kak is used for coloring various foods, and as a color additive for manufacturing fermented food such as sufu, red wine, fish sauce, and fish paste in the Orient.

M. purpureus NRRL 2897 maintained in the AR Culture Collection was isolated from an ang-kak sample bought in the Philippines market and has been demonstrated to carry out the fermentation successfully. Palo et al. (1960) studied various conditions of the fermentation and found that the optimum temperature for pigment formation is about 27°C.

Growth will occur as low as 20°C and as high as 37°C, but at these extremes poor pigmentation results. The mold will produce the pigment over a wide range of pH values (3 to 7.5). All varieties of rice are suitable except the glutinous ones, which are unsatisfactory because the rice becomes gluey and the grains stick together.

The procedure for preparing ang-kak on a laboratory scale as developed by Palo et al. (1960) is to first wash the rice, soak it in water 24 hr, and then drain it thoroughly. The rice is placed in a beaker or other suitable container that is large enough to have considerable air space above the rice.

It is then covered with a milk filter disc, autoclaved for 30 min at 121°C, cooled, and inoculated with a sterile water suspension of ascospores removed from 25-day-old cultures of M. purpureus grown on Sabouraud’s agar. This medium is excellent for growth and pigment production. The culture should show much red color on this medium. After the suspension is thoroughly mixed with the rice, it should be incubated at from 25° to 32°C.

At the time of inoculation the rice will seem rather dry, but this state is one of the secrets to the production of good ang-kak. The rice should never be wet or mushy. In 3 days, the rice should begin to redden. At this time, the material should be stirred and shaken to redistribute the rice in the center and bottom of the fermentor to retain even moisture at the surface. We have found that an occasional vigorous shaking of the fermentation jar is quite adequate.

Addition of some sterile water may be required from time to time to replace lost moisture. Care must be taken only to moisten and not to soak the rice. In 3 weeks, the rice should be a deep purplish-red with each rice kernel unattached to its neighbors. The material is then dried in an oven at 40°C. When the kernels are broken, the pigment should have infiltrated completely through the rice. Each grain should crumble easily between one’s fingers.

Lin (1973) isolated a strain of Monascus sp. F-2 from kaoliang koji and found that it produced large amounts of pigment by submerged culture with rice as a sole carbon source. N-Methyl-N’-nitro-N-nitrosoguanidine treatment and successive isolation greatly improved the yield of the pigment production by Monascus sp. F-2. Two hyperpigment- producing strains, R-1 and R-2, were isolated which produced 5 times more red pigment than the original parent strain F-2 did.

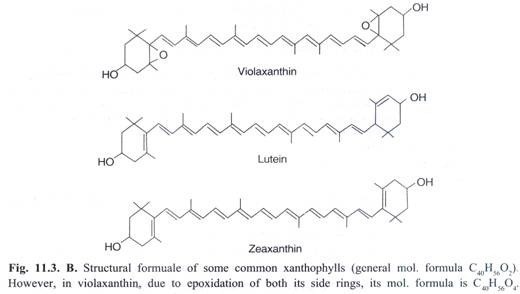

The ang-kak studied by Nishikawa (1932) consisted of 2 pigments, principally monascorubrin, and a red coloring material with a formula of C22H24O5, and a small amount of monascoflavin, a yellow pigment (C17H22O4). The pigments tend to accumulate in the microorganisms because of their poor solubility. Recently Yamaguchi et al. (1973) reported that the pigment can be solubilized by reacting it with a water-soluble protein, a water-soluble peptide, an amino acid, or a mixture of these. The-reaction is carried out at pH from 5 to 8.5 and requires from several minutes to several hours. As the reaction progresses, the color of the pigment changes from a brownish-red to a deep scarlet and the pigment becomes water soluble.

The solubility of the pigment in water varies with the type of protein, peptide, or amino acid used. The same authors also indicated that the water-soluble pigment can be produced directly by the mold grown in a medium containing soluble protein, peptide, or amino acid at a pH of 7-9 under aerobic conditions and at a temperature of about 27°C for 48 to 72 hr.

The mechanism of this reaction is not clear; the authors speculated that the water-soluble pigment is a complex resulting from binding between the pigment and the chosen amino group. The water-soluble pigment is suitable for coloring foodstuffs, particularly sour-type drinks, candy, milk products, and meat products.

Oriental Fermented Food # 6. Fermented Fish Products:

Parallel with fermented soybean products, soy sauce, and miso (soybean pastel are two fermented fish products—fish sauce and fish paste. These products have a long tradition as a food condiment in the Orient. Both fish and soybean fermentations involve the use of large amounts of salt to select certain organisms and to inhibit food-poisoning ones; both are carried out under semi-anaerobic if not actual anaerobic conditions; both involve enzymes that break protein down into amino acids; and both are highly flavored and complement a bland rice diet. However, soy sauce and miso fermentations have become highly technological operations, whereas the fish fermentation remains a traditional one.

Many different types of fish sauce and fish paste are obtained through lengthy but simple fermentation processes. Whole small fish with viscera or shrimp are heavily salted, packed into a sealed container, and allowed to undergo natural fermentation for periods varying from a few days to more than a year.

Therefore, most of these products are the results of enzymatic digestion ensuing from tissue, especially viscera, or from microorganisms. In fish paste fermentation, other materials such as roasted rice powder, red rice, and pineapple are frequently added, and the whole fermented mass is ground into a fine paste.

Fish sauce, on the other hand, is the liquid fraction of the fermented mass. It is usually a clear yellow to amber liquid rich in salt and soluble nitrogen compounds. Both fish paste and sauce have a distinctive odor and flavor, generally not appreciated by Westerners. The products are described as having a characteristic salty cheese flavor and a slight fish odor.

The fermented fish products are especially popular in Southeast Asia and are consumed by almost everyone. To the rich, these products add zest to the food; to others, they make the bland rice and vegetable diet more palatable. Fish sauce and fish paste made in various countries are known under different names, such as ngam-pya-ye and ngapi for fish sauce and fish paste, respectively, in Burma; nuoc-mam and mams in Cambodia and Vietnam; patis and bagoong in the Philippines; and nampla and kapi in Thailand.

Although the basic principles of making these products are the same, a large number of variations develop. By following more or less constant techniques over hundreds of years, each country develops a fairly standardized product having the characteristic texture, appearance, and flavors that appeal to its own people. However, scientific studies on these products are scanty.

Nuoc-mam, a Vietnam fish sauce, has been studied by a number of investigators. Because many of the findings may be applicable to other fermented fish products in Southeast Asia, an account of nuoc-mam is given.

The production of nuoc-mam is a very active industry in Vietnam. It is produced in large plants as well as in so-called cottage industries. Total production was estimated at 40 million liters per year in the early 1970s, and daily per capita consumption ranged from 15 to 60 ml depending on one’s income, with greater consumption for low-income people.

In the most primitive way of manufacturing nuoc-mam, small fish are kneaded and pressed by hand. They are salted and tightly packed into earthenware pots which are sealed and buried in the ground for several months. When the pots are opened, the supernatant liquid or the pickle that has been formed is decanted. This liquid is the nuoc-mam.

In the commercial production of nuoc-mam cylindrical vats made with local wood and encircled with twisted bamboo are used. The vats are equipped with taps near the bottom. The inside end of the tap is buried beneath shells, sometimes mixed with rice husks, and the inside opening is plugged with hairs in order to improve the filtering power.

The fresh, un-cleaned fish are mixed with a small amount of salt and packed in the vat in alternate layers with additional salt. A final layer of salt is placed on the top. After 3 days, the collected liquid, known as nuocboi, is drained off and reserved for later use. Meanwhile, the fish have settled below the top of the vat, and the salt has almost disappeared.

The fish are now packed down thoroughly, and the surface is smoothed. The contents are covered with a layer of coconut leaves and then with bamboo trays on top of which weights are placed. The drained nuocboi is poured back into the vat so that a layer of liquid, about 10 cm, covers the fish. The fish are now left to ferment.

Fermentation time varies with the kind of fish used, ranging from a few months for small fish to 1 year or 18 months for large fish. The amount of salt also varies with the species of fish used, usually 1 part of salt for every 1-1.5 parts offish by volume. Generally, the higher the concentration of salt and the more the proteins are hydrolyzed to products of low molecular weight, the better will be the keeping quality of the nuoc-mam.

After maturing, the liquid is run off through the tap at a rate of 300-400 liters per day; this is first quality nuoc-mam. A product of less quality is then obtained by extracting the residual mass with fresh brine solution. The un-dissolved residue is usually sold as manure. In some countries, the residue is not repeatedly extracted but is used as fish paste.

One part of fish gives from 2 to 6 parts of nuoc-mam depending upon the nitrogen content of the end product. Because nuoc-mam is an important item in the diet of the people of Vietnam, its manufacturing, trade, and quality are strictly controlled by governmental legislation. The quality of nuoc-mam depends upon the quantity of fish, the degree of fermentation, and the nutritive value.

The quantity of fish is assessed by the total nitrogen in nuoc-mam, not less than 16 g/liter being the first class; the degree of fermentation is based on the formol titratable nitrogen, not less than 50% of total nitrogen; nutritive value is evaluated by the amount of ammonia nitrogen, not more than 50% of formol nitrogen. The average composition of nuoc-mam is given in Table 12.7.

Nuoc-mam has a high content of methyl ketones which probably accounts for the cheese-like odor. The same author found that nuoc-mam did not contain significant amounts of thiamin, riboflavin, or pyridoxine. The product, however, was found to contain 25-200 μg of vitamin B12 per liter.

The hydrolysis offish protein appears to be due mainly to the enzymes in the fish. Glycerol extracts of the fish internal organs were found especially active, even in the presence of salt. Baens-Arcega et al. (1969) found that the addition of proteolytic enzymes from Aspergillus oryzae to the fermentation mass could greatly reduce fermentation time and increase yield.

Salt does retard the rate of enzymatic action, but it also reduces the growth of putrefactive bacteria which are responsible for the off-flavor of the fermented product. However, the product made aseptically lacked the typical flavor of nuoc-mam. Therefore, some microorganisms might be responsible for the characteristic flavor.

Boez and Guillerm (1930A.B) have isolated anaerobic, spore-forming bacteria belonging to the Clostridium group said to produce the typical flavor of nuoc-mam. Saisithi et al. (1966) investigated the fish sauce made in Thailand and found that the total viable counts decreased as the fermentation advanced.

Approximately 70% of the isolates from a 9-month-old fish sauce were halophiles of bacillus types. These isolates were found to produce volatile acid; the largest amount of acid, however, was produced by Staphylococcus strain 109. They extracted the compounds responsible for the aroma from the fish sauce with diethylether-alcohol mixture and separated them with ion exchange chromatography.

The typical aroma fraction was eluted from the ion exchange resin with 4 N formic acid, suggesting that it is probably an acid. Silica gel thin layer chromatography further revealed the presence of amino acids as well as amines, glucosamine, histamine, glutamine, and tri-methylamine. The aroma present in the fish sauce, therefore, could be a blend of acids and amines; the bacteria obviously play a role in the forming of these compounds.

Oriental Fermented Food # 7. Miso:

Miso is the Japanese name given to paste-like products made by fermenting cereal, soybeans, and salt with molds, yeasts, and bacteria. Similar products are also made and consumed in other parts of the Orient. Each nation has its own name for the product- chiang in China; tauco in Indonesia; doenjang in Korea; and tao-chieo in Thailand. Literally, they all mean bean paste. Bean paste has the consistency of peanut butter, some smooth and some chunky, and its color varies from light yellow to reddish-brown.

It has a distinctive pleasant aroma resembling that of soy sauce, and it is typically salty, although the degree of saltiness may vary; some may even have a sweet taste. Like soy sauce, bean paste is used as a flavoring agent in cooking as well as a table condiment. It is used in place of soy sauce and salt to prepare special flavored foods. These products blend well with varieties of foods including fish, meats, and vegetables.

Variations of bean paste are innumerable. In Japan alone, there are as many types of miso as there are different varieties of cheese in the United States. They are made by varying the cereal used, the ratios of beans to cereal, salt content, length of fermentation, and addition of other ingredients such as hot pepper, which is very popular in China and Korea.

Although the manufacturing method may differ from country to country, or from variety to variety, the principle is believed to be the same. This account will be general in nature and follows the procedures for making Japanese miso, because much of the literature on the subject has resulted from studies on Japanese miso. Laboratory methods of making miso have been investigated in the United States by Hesseltine and his coworkers.

Miso, the most popular fermented food in Japan, is typically used in soup served hot every morning in almost every Japanese home. The soup usually consists of seasonal vegetables with the addition of a spoonful of miso as flavoring agent. About 590,000 MT of commercial miso (Table 12.1) and 150,000 MT of homemade miso are produced in Japan annually. The per capita yearly consumption is about 6.7 kg.

According to Ebine (1971), Japanese miso is categorized into 3 major types based on the raw materials used: rice miso made from rice, soybeans, and salt; barley miso from barley, soybeans, and salt; and soybean miso from soybeans and salt. These 3 types are further classified on the basis of taste into sweet, medium salty and salty groups; each of these groups is again divided by color into white, light yellow, and red. Approximately 80% of the total industrial production is rice miso.

The production process, as shown in Fig. 12.2, generally consists of cooking soybeans, preparing koji, mixing cooked soybeans with rice koji and salt, fermenting and ripening in a tank, blending, pasteurizing, and then packing. The characteristics of 3 types of rice miso in relation to the fermentation conditions are presented in Table 12.3. With respect to microorganisms and fermentation principles, miso and soy sauce fermentations are similar.

Whole soybeans are generally used for making miso. Dehulled soybeans or full-fat soybean grits are sometimes used for making white or light yellow rice miso. A patent by Smith et al. (1961) covers the use of grits. Unlike soy sauce fermentation, in which over 90% of shoyu produced in Japan is made from defatted soybean products, defatted soybean products are not suitable for making miso of good quality.

Soybean quality is of utmost importance in miso fermentations. The soybean variety was found to significantly affect the quality and organoleptic scores of the final product. In general, the miso industry prefers to use soybeans of a large size (more than 170 g/1000 seeds) because the ratio of hull to cotyledon is lower in the large beans.

Soybeans that have a pale yellow hull and hilum are especially acceptable for making white or light yellow miso. The soybean should have high water-absorbing capacity, and when cooked under the described conditions, the beans should be homogeneously soft with fine texture and bright color. A bright color of the cooked beans is extremely important when white miso or light yellow miso is made.

The Japanese miso makers found the domestic soybeans to be the most suitable, followed by Chinese and then United States soybeans. The major difference between Japanese and U.S. soybeans is in the amounts of oil and carbohydrates (total sugar); the Japanese varieties have a higher carbohydrate and lower oil content than United States varieties.

Tests have shown no correlation between the capacity to absorb water and the protein and oil content, but there is a high correlation between carbohydrate content and water-absorbing capacity. Among the United States varieties tested, Kanrich, Mandarin, and Comet are the most promising ones.

To prepare whole soybeans for fermentation (Fig. 12.2), they are washed, soaked in water for about 20-hr at 16°C, and drained. The soaked beans are -then cooked in water (white miso) or steamed at a temperature of 115°C for about 20 min in a closed cooker. The new batch-type cooker used in the shoyu fermentation, in which the temperature can be raised rapidly to 120°C and lowered quickly immediately after cooking, has also been introduced to the miso industry.

For koji preparation, polished rice is used since it is essential that the mold mycelium quickly penetrate the rice kernels. Polished rice is soaked in water (15°C) overnight or until the moisture content is about 35%. Excess water is drained off, and the soaked rice is steamed at atmospheric pressure for 40 min. A continuous cooker was developed and is now widely used for cooking rice and barley.

The belt conveyor in this type of cooker allows substantial savings in time and labor. After the steamed rice is cooled to 35°C, tane koji is sprayed over the rice and mixed well. One gram of tane koji (koji inoculum) containing 109 or more viable spores is recommended for the inoculation of 1 kg of raw rice. Tane koji for miso fermentation is a blended mixture of several different strains of A. oryzae (e.g., A. oryzae NRRL 3484, 3485, and 3488) prepared as described under “Soy Sauce.”

The inoculated rice is then incubated in a temperature- and humidity-controlled room. Koji fermentors of various types are now used instead of koji rooms; a rotary fermentor is the most popular. The temperature and humidity of the air in the fermentor can be regulated so as to promote growth and enzyme production of the mold.

In about 40-48 hr at 30°-35°C, the rice is completely covered with white mycelium of the inoculated A. oryzae strains. Harvesting is done while the koji is white and before any sporulation has occurred. At this time, the koji has a pleasant smell, lacks any musty or moldy odors, and is quite sweet in taste. The koji is removed from the fermentor and mixed well with salt to stop any further development of the mold.

The next fermentation is carried out under anaerobic conditions by yeast and bacteria. Cooked soybeans are slightly mashed and mixed with the salted koji, and then inoculated with a starter containing pure cultures of yeasts and bacteria. The well-blended mixture, now known as green miso, is tightly packed into a vat or tank for fermentation at around 25°-30°C.

Fermentation time varies widely, depending on the type of miso desired; for example, white miso takes 1 week, salty miso 1-3 months, and soybean miso over 1 year. During the fermentation period, the green miso is transferred from one vat to another at least twice to improve fermentation conditions. At the end of the fermentation, the mass is kept at room temperature for about 2 weeks to ripen. The aged product is then blended, mashed, pasteurized, and packaged.

In the past, miso from a previous batch was used as the inoculum of bacteria and yeast; however, the present pure culture starters speed up the fermentation and reduce the influence of weed yeasts and bacteria. Strains of Saccharomyces rouxii, Torulopsis, Pediococcus halophilus, and Streptococcus faecalis are the most important yeasts and bacteria in the miso fermentation. Although the industrial strains are not readily available, S. rouxii NRRL Y-2547 maintained in the ARS Culture Collection was isolated from miso.

The yield of miso is determined by the length of fermentation and ripening, type, and moisture content. Generally, 3300 kg of light yellow salty miso with a moisture content of 48% is made from 1000 kg of soybeans, 600 kg of rice, and 430 kg of salt.

Since different types of miso are made by varying the ratios of the raw materials, the composition of miso varies with the type. Table 12.4 presents the standard chemical composition of several types of miso as reported by Ebine (1971). Miso has a fairly narrow moisture range of 44-50%.

Protein content ranges from 8 to 19% and fat from 2 to 10%, reflecting the increase of soybean used in the fermenting mixture. Except for the white and sweet types, miso contains more than 10% salt. Because of the high salt concentration, miso may be kept for considerable periods without refrigeration; but, for the same reason, the use of miso as a protein food is limited.

To reduce the salt concentration of miso products, enzyme-digested soybean mash has been investigated. Defatted soybean meals are sprayed with an equal weight of water and then steamed under pressure (0.7 kg/cm2) for 40 min. The enzyme preparation, Takadiastase SS, is added to the cooked material at the level of 0.2%, and the digestion is carried on for 3-4 hr. The enzyme-digested soybean mash is then mixed with miso and allowed to ripen for several days. The new type of miso has about 6.3% salt and 17.6% protein.

Miso has a strong buffer activity due to the presence of protein, peptides, amino acids, phosphoric acid, and various organic acids produced during the fermentation. This property plays an important role as a seasoning in a variety of foods to which miso renders a palatable flavor.

The strong characteristic flavor and the salty taste of miso are not familiar to Westerners, and it may even be considered offensive to some. However, when miso is used in small amounts as a flavoring agent to enhance or to alter the flavor of a food, the taste is distinct and pleasant.

Recently, we have taken a look at Western cookery and have found that miso can substitute or replace part of tomato paste, mayonnaise, and salt in recipes for salad dressings, barbeque sauces, snack dips, and spreads. The resulting miso-containing products can be considered new items, because they have a distinctly different flavor consumers can easily detect that is mild and non-offensive.

These miso-containing items are similar in appearance and texture to existing products in the same category, and they are used in the same way. The future potential for miso in the United States is good. Perhaps the research on the miso fermentation should be focused on using defatted soybean products as substrate and on reducing the salt concentration of the final product.

Oriental Fermented Food # 8. Sufu:

In the Western world, sufu has been referred to either as Chinese cheese or bean cake. Both names give a good description of the product. Sufu is a soft cheese-type product made from cakes of soybean curd (tofu) by the action of a mold. It is widely consumed by Chinese, but is not generally known by other Orientals.

Because of the numerous dialects used in China, the product is also known as fu-ju or tou-fu-ju by many Chinese. Chao of Vietnam, tahuri of the Philippines, taokoan of Indonesia, and tao-hu-yi of Thailand are the same as sufu, and are usually consumed by Chinese immigrants.

The process of making sufu was considered a natural phenomenon. Not until 1929 was a microorganism believed to be responsible for sufu fermentation isolated and described by Wai (1929). He identified the microorganism to be an undescribed species of Mucor and proposed the name Mucor sufu.

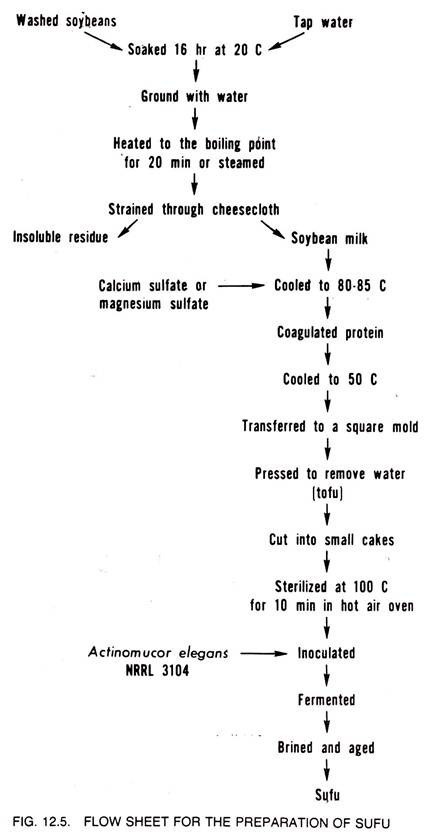

Wai also thought that this fungus originated on rice straw, because rice straw was always used to cover the tofu cubes for fermentation in the traditional way. Almost 40 years later, Wai (1968) reinvestigated the microorganism in sufu fermentation; as a result, pure culture fermentation for making sufu was developed. His report was summarized by Wang and Hesseltine (1970A). Three steps are normally involved in making sufu- preparing tofu, molding, and brining (Fig. 12.5).

To make tofu, soybeans are first washed, soaked overnight, and then ground with water, water to dry bean ratio of 10:1 is commonly used. After boiling or steaming the ground mass for about 20 min, the hot mass is strained through a cloth bag, double-layered cheesecloth, or a fine metal screen to separate the soybean milk from the insoluble residue.

Curdling is achieved by the addition of a coagulant, such as calcium salts, magnesium salts, and acid. The curd is then transferred into a cloth-lined wooden box and pressed with weight on top to remove whey. A soft but firm cake-like curd tofu forms. So, tofu is to soybean milk what cottage cheese is to cows’ milk, except that the curdling of soybean milk is traditionally brought about by a calcium salt and only occasionally by acid.

Tofu has a bland taste and high water content (about 90%). It can be consumed directly and is so eaten extensively throughout the Far East. But the water content of tofu for making sufu is lower than that of tofu consumed directly; otherwise, it is likely to be spoiled by bacterial growth. Typically, tofu used for sufu fermentation has water content of 83%; protein, 10%; and lipids, 4%.

To prepare tofu for fermentation, the cubes (2.5 x 3 x 3 cm) are first soaked in a solution containing 6% NaCl and 2.5% citric acid for 1 hr, and then subjected to hot air treatment at 100°C for 15 min. This treatment prevents growth of contaminating bacteria but does not affect the growth of fungi needed in making sufu.

Tofu cubes should be separated from one another and placed in a tray with pinholes in the bottom and top to aid air circulation because mycelia must develop on all sides of the cubes. After cooling, the cubes are then inoculated over their surfaces by rubbing with a pure culture of an appropriate fungus grown on filter paper impregnated with a culture solution.

The inoculated cubes are incubated at 20°C or lower for 3-7 days depending on the culture. The freshly molded cubes, known as pehtze, have a luxurious growth of white mycelium and no disagreeable odor. The pehtze has water content of 74%; protein, 12.2%; and lipid, 4.3% as reported by Wai (1968).

In order to obtain a fermented product of good quality, the mold used in this fermentation has to have certain qualities. The organism probably utilizes the carbon in lipids as an energy source, because proper types of carbohydrates are not readily available in the substrate.

The organism must develop enzyme systems having high proteolytic and lipolytic activity, since the mold grows on a protein- and lipid-rich medium. The mold must have white or light yellowish-white mycelium to ensure that the final product has an attractive appearance.

The texture of the mycelial mat should also be dense and thick, so that a firm film will be formed over the surface of the fermented tofu cubes to prevent any distortion in their shape. Of course, it is also important that the mold growth not develop any disagreeable odor, astringent taste, or mycotoxin. Dr. Wai and his coworkers confirmed that Actinomucor elegans, Mucor hiemalis, Mucor silvaticus, and Mucor subtilissimus possess all these characteristics and can be used to make good quality sufu. Among them A. elegans seems to be the best organism and is the one used commercially in the Orient.

The last step in making sufu is brining and aging. The molded cubes can be placed in various types of brine solutions, according to the flavor desired. Basic and most common brine suitable to Chinese taste is one containing 12% NaCl and rice wine containing about 10% ethyl alcohol. The immersed cubes are allowed to age for about 40-60 days. The product is then bottled with the brine, sterilized, and marketed as sufu.

Freshly molded tofu is bland in taste. The flavor and aroma of sufu develop during the brining and aging process. Other additives, either to give color or flavor, are frequently incorporated into the brine. Red rice and soy mash are added to the brine, imparting a red color to the product; when these ingredients are added, the final product is known as red sufu or hon-fang.

Fermented rice mash or a large amount of wine can be added to the brine, so that the product has more of the alcoholic bouquet. This product is known as tsui-fang or tsue-fan, which means drunken sufu. The addition of hot pepper to the brine would make hot sufu. Rose sufu can be made by aging in brine containing rose essence. Therefore, the taste and aroma of sufu, in addition to its own characteristically mild one, can be easily enhanced or modified by the ingredients of the brine solution.

During the brining and aging process, the enzymes elaborated by the mold act upon their respective substrates, yielding various hydrolytic products. Since sufu fermentation has a rather simple substrate—55% protein and 30% lipids on a dry basis—it is likely that the hydrolytic products of protein and lipids provide the principal constituents of the mild characteristic flavor of sufu. The added alcohol reacts with the fatty acids chemically or enzymatically to form esters providing the pleasant odor of the product. Ethanol also prevents the growth of microorganisms.

The added salt imparts a salty taste to the product, as well as retarding mold growth and growth of contaminated microorganisms. Most important, the salt solution releases the mycelia-bound proteases. In sufu fermentation, the mold growth is limited to the surface of the cubes, and the mycelium does not penetrate into the tofu cubes. The enzymes produced by the mold, on the other hand, are not extracellular.

They are loosely bound to the mycelium, possibly by ionic linkage. However, the enzymes can be easily eluted by NaCl or other ionic salt solutions, but not by water or non-ionizable salt. Therefore, the NaCl brine solution also serves to elute the enzyme from mycelia which, in turn, penetrate into the molded cubes and act upon the substrate protein.

Changes which occur during the aging process have also been studied by Wai (1968). After 30 days of aging at room temperature, total soluble nitrogen increased from 1.00 to 2.74% and total insoluble nitrogen decreased from 7.89 to 6.05%, while total nitrogen changed slightly.

The soluble nitrogenous compounds were reported to consist of soluble proteins, peptides, and amino acids, including aspartic acid, serine, alanine, leucine isoleucine, and glutamic acid. Lipids in pehtze were also partially hydrolyzed through the aging period. Free fatty acids increased from 12.8 to 37.1% and total lipids remained unchanged.

Traditionally, sufu is consumed directly as a relish or is cooked with vegetables or meats. Either way, sufu adds a zest to the bland taste of a rice-vegetable diet. Because sufu has the texture of cream cheese, it would be suitable to use in Western countries as a cracker spread or as an ingredient for dips and dressings.

The traditional product, however, has too high a salt content to suit Westerners’ taste; nonetheless, a less salty product can be obtained by reducing the salt concentration of the brine solution from 12% to not less than 3%, which is the minimal salt concentration to release the mycelium-bound proteases.