In this article we will discuss about the methods and procedures to made yogurt. Learn about:- 1. Yogurt Ingredients and Rheological Aspects 2. Fruit Preparations for Flavoring Yogurt 3. Yogurt Starter and Its Contribution to Texture and Flavor 4. Manufacturing Procedures 5. Manufacturing of Frozen Yogurt 6. Yogurt Quality Control.

Contents:

- Yogurt Ingredients and Rheological Aspects

- Fruit Preparations for Flavoring Yogurt

- Yogurt Starter and Its Contribution to Texture and Flavor

- Manufacturing Procedures of Yogurt

- Manufacturing of Frozen Yogurt

- Yogurt Quality Control

1. Yogurt Ingredients and Rheological Aspects:

The manufacture of yogurt has recently been reviewed by Humphrevs and Plunkett (1969), Robinson and Tamine (1975), Kroger (1976) and Kosikowski (1977).

Dairy Ingredients:

Yogurt is generally made from a mix standardized from whole, partially defatted milk, condensed skim milk, cream and nonfat dry milk. Alternatively, milk may be partly concentrated by removal of 15-20% water in a vacuum pan. Supplementation of milk solids- not-fat with nonfat dry milk is the preferred industrial procedure.

All dairy raw materials should be selected for high bacteriological quality. Ingredients containing mastitis milk and rancid milk should be avoided. Also, milk partially fermented by contaminating organisms and milk containing antibiotic and sanitizing chemical residues cannot be used for yogurt production.

The procurement of all ingredients should be based upon specifications and standards which are checked and maintained with a systematic sampling and testing program by the quality control laboratory. Since yogurt is a manufactured product, it is likely to have variations according to the quality standards established by marketing considerations. Nonetheless it is extremely important to standardize and control the day-to-day product in order to meet consumer expectations and regulatory obligations associated with a certain brand or label.

The milk fat levels in yogurt range from 1.0 to 3.25%. The proposed federal standards of identity define the product in 3 categories.

The product containing a minimum of 3.25% milk fat is termed yogurt. Low-fat yogurt contains not less than 0.5% and not more than 2% milk fat. The product containing less than 0.5% milk fat is labeled as nonfat yogurt. In all the categories of yogurt, a milk solids-not-fat minimum of 8.25% and a titratable acidity minimum of 0.5% lactic acid are stipulated.

The ingredients defined are- cream, milk, partially skimmed milk, skim milk alone, or in combination. Concentrated skim milk, nonfat dry milk, or other milk derived ingredients may be used to standardize milk solids-not-fat content of a mix. Presumably, the milk derived ingredients include casein, sodium and calcium caseinates, whey, and whey protein concentrates alone or in combination.

The use of milk derived ingredients is conditional in that the ratio of protein to total nonfat solids of the food and the protein efficiency ratio of all protein present should not be diminished by their use. Additives permitted are nutritive carbohydrate sweeteners, coloring, stabilizer, and fruit preparations for flavoring yogurt. The culture is specified as a mixture of Lactobacillus bulgaricus and Streptococcus thermophilus.

Sweeteners:

Nutritive carbohydrates used in yogurt manufacture are similar to the sweeteners used in ice cream and other frozen desserts described by Arbuckle (1977). Sucrose is the major sweetener used in yogurt production. Sometimes, corn sweeteners and honey may also be used. The level of sucrose in yogurt mix appears to affect the production of lactic acid and flavor by yogurt culture.

Bills et al. (1972) reported a decrease in acetaldehyde production at 8% or higher concentration of sucrose. Sucrose may be added in a dry, granulated, free-flowing, crystalline form or as a liquid sugar containing 67% sucrose. Liquid sugar is preferred for its handling convenience in large operations. However, storage capability in sugar tanks along with heaters, pumps, strainers, and meters is required.

The corn sweeteners, primarily glucose, usually enter yogurt via the processed fruit flavor in which they are extensively used for their flavor enhancing characteristics. Up to 6% corn syrup solids are used in frozen yogurt. Non-nutritive sweeteners (e.g., Ca-saccharin) have been used along with maltol to produce a product containing about 50% of the calories of normal sweetened yogurt.

Lactase has been suggested for hydrolysis of lactose to a sweeter mixture of glucose and galactose in yogurt, thereby reducing the level of sucrose required to achieve a constant degree of sweetness. Goodenough and Kleyn (1976) investigated qualitative and quantitative changes in yogurt during its manufacture.

They reported average lactose concentration of 8.5% in yogurt mix. Upon fermentation, the lactose level dropped to 5.75% with a concomitant increase of 1.20% galactose. Glucose was detected only in trace quantities. Commercial yogurts had an average of 4.06% lactose, 1.85% galactose, 0.05% glucose, and pH of 4.15.

Stabilizers:

The primary purpose of using a stabilizer in yogurt is to produce smoothness in body and texture, impart gel structure, and reduce wheying off or syneresis. The stabilizer increases shelf life and provides a reasonable degree of uniformity of the product. Stabilizers function through their ability for form gel structures in water, thereby leaving less free water for syneresis. In addition, some stabilizers are complex with casein.

A good yogurt stabilizer should not impart any flavor, should be effective at low pH values, and should be easily dispersed in the normal working temperatures in a dairy plant. The stabilizers generally used in yogurt are gelatin, vegetable gums like carboxymethyl cellulose, locust bean and guar, and seaweed gums like alginates and carrageenans.

Gelatin is derived by irreversible hydrolysis of the proteins collagen and ossein. It is used at a level of 0.3-0.5% to get a smooth shiny appearance in refrigerated yogurt. Gelatin is a good stabilizer for frozen yogurt. The term Bloom refers to the gel strength as determined by a Bloom gelometer under standard conditions.

Gelatin of Bloom strength of 225 or 250 is commonly used. The gelatin level should be geared to the consistency standards for yogurt. Amounts above 0.35% tend to give yogurt of relatively high milk solids a curdy appearance upon stirring. At temperatures below 10°C, the yogurt acquires a pudding-like consistency.

Gelatin tends to degrade during processing at ultrahigh temperatures and its activity is temperature dependent. The yogurt gel is considerably weakened by a rise in temperature. Furthermore, being an animal product, gelatin is generally not acceptable in Kosher yogurts.

The seaweed gums impart a desirable viscosity as well as gel structure to yogurt. Algin and sodium alginate are derived from giant sea kelp. Carrageenan is made from Irish moss and compares with 250 Bloom gelatins in stabilizing value. These stabilizers are heat stable and promote stabilization of the yogurt gel by complex formation with Ca++ and casein.

Among the seed gums, locust bean gum or carob gum is derived from the seeds of a leguminous tree. Carob gum is quite effective at low pH levels. Guar gum is also obtained from seeds and is a good stabilizer for yogurt. Guar gum is readily soluble in cold water and is not affected by high temperatures used in the pasteurization of yogurt mix. Carboxymethyl cellulose is a cellulose product and is effective at high processing temperatures.

The stabilizer system used in yogurt mix preparations is generally a combination of various vegetable stabilizers to which gelatin may or may not be added. Their ratios as well as the final concentration (generally 0.5-0.7%) in the product are carefully controlled to get desirable effects. Other stabilizers reportedly used are agar and pectin. CaCl2 may be useful in controlling whey separation.

2. Fruit Preparations for Flavoring Yogurt:

The fruit preparations for blending in yogurt are specially designed to meet the marketing requirements for different types of yogurt. They are generally present at levels of 15-20% in the final product. A majority of the fruits contain natural flavors.

The following types of yogurts are marketed in the United States:

1. Fruit-on-Bottom or Eastern Sundae Style Yogurt:

In this type, 59 ml (2 oz) of fruit preserves are layered at the bottom followed by 177 ml (6 oz) of inoculated yogurt mix on the top. No flavor or sweetener is added to the yogurt layer. After placing lids on the cups, incubation and setting of the yogurt takes place in the cups. When a desirable pH of 4.2-4.4 is attained, the cups are placed in refrigerated rooms for rapid cooling. For consumption, the fruit and yogurt layers are mixed by the consumer. Fruit preserves have a standard of identity.

A fruit preserve consists of 55% sugar and a minimum of 45% fruit which is cooked until the final soluble solids content is 68% or higher (65% in the case of certain fruits). Frozen fruits and juices are the usual raw materials. Commercial pectin, 150 grades, is normally utilized at a level of 0.5% in preserves and the pH is adjusted to 3.0-3.5 with a food-grade acid, viz., citric, during manufacturing of the preserves.

2. Western Sundae Style Yogurt:

In this type, fruit preserves or special fruit preparations may form the bottom layer. The top layer consists of yogurt containing sweeteners, with the flavor and color indicative of the fruit on the bottom. The flavor level is usually 2-4% in the top layer. In other respects, this yogurt is identical to Eastern Sundae Style.

3. Swiss-Style Yogurt:

Also known as Continental Style, French Style, and Stirred yogurt, the fruit preparation is thoroughly blended in yogurt after culturing. Stabilizers are necessary in this form of yogurt unless milk solids-not-fat levels are relatively high (14-16%). In this style, cups are filled with a blended mixture of yogurt and fruit.

Upon refrigerated storage for 48 hr, the clot is reformed to exhibit a fine body and texture. Over-stabilized yogurt possesses a solid-like consistency and lacks a refreshing character. Yogurt should not be so thin that it can be drunk. It should melt in the mouth without chewing.

Flavors and certified colors are usually added to the fruit-for-yogurt for improved eye appeal and better flavor profile. The fruit base should meet the following requirements. It should (a) exhibit true color and flavor of the fruit when blended with yogurt, and (b) be easily dispersible in yogurt without causing texture defects, phase separation, or syneresis. The pH of the fruit base should be compatible with the yogurt pH.

The fruit should have low yeast and mold population in order to prevent spoilage and to extend shelf life. Fruit preserves do not necessarily meet all these requirements, especially of flavor, sugar level, consistency, and pH.

Accordingly, special fruit bases of the following composition (in %) are designed for use in Stirred yogurt:

1. Fruit – 17 to 41%

2. Sugar – 22 to 40%

3. Corn syrup solids – 10 to 24%

4. Modified food starch – 3.5 to 5.0%

5. Fruit flavor, artificial – 0.1%

6. or natural – 1.25%

7. Color – 0.01% or to specifications

8. Potassium sorbate Citric acid to pH 3.7 to 4.2 – 0.1%

CaCl2 and certain food-grade phosphates are also used in several fruit preparations. The soluble solids range from 60 to 65% and viscosity is standardized to 5 ± 1.5 Bostwick units (cm), 30 sec reading at 24°C. Standard plate counts on the fruit bases are generally less than 500/g. Coliform count and yeast and mold count are less than 10/g. The fruit flavors vary in popularity in different parts of the country and during different times of the year.

In general, more popular fruits are- strawberry, raspberry, blueberry, peach, cherry, orange, lemon, purple plum, boysenberry, spiced apple, apricot, and pineapple. Blends of these fruits are also popular. Fruits used in yogurt base manufacture may be frozen, canned, dried, or combinations thereof.

Among the frozen fruits are strawberry, raspberry, blueberry, apple, peach, orange, lemon, cherry, purple plum, blackberry, and cranberry. Canned fruits are- pineapple, peach, mandarin orange, lemon, purple plum, and maraschino cherry. The dried fruit category includes apricot, apple, and prune. Fruit juices and syrups are also incorporated in the bases.

Sugar in the fruit base functions in protecting fruit flavor against loss by volatilization and oxidation. It also balances the fruit and the yogurt flavor. The pH control of the base is important for fruit color retention. The color of yogurt should represent the fruit color in intensity, hue, and shade. The base should be stored under refrigeration to obtain optimum flavor and to extend the shelf life.

3. Yogurt Starter and Its Contribution to Texture and Flavor:

The starter is a critical ingredient in yogurt manufacture. Tramer (1973) and Davis (1975) have discussed practical aspects of yogurt culture. Freedom from contaminants, vigorous growth in yogurt mix, good flavor, body, and texture production and a reasonable resistance to phages and antibiotics are primary requirements of a yogurt culture.

Equal cell numbers of Lactobacillus bulgaricus and Streptococcus thermophilus are desirable for flavor and texture production. The lactobacilli grow first, liberating the amino acids glycine and histidine, and stimulating the growth of streptococci. Tramer (1973) demonstrated differences in the comparative ability to produce acid by various strains of yogurt cultures in commercially autoclaved versus heat-treated (95°C, 30 min) milk. The rate of acid production by yogurt culture should be synchronized with plant production schedules. Using frozen culture concentrates, incubation periods of 5 hr at 45°C, 11 hr at 32°C, or 14-16 hr at 29°-30°C are required for yogurt acid development.

Using bulk starters at 1% inoculum level, the period is 2.5-3.0 hr at 45°C, 8-10 hr at 32°C, or 14-16 hr at 29°-30°C. Stone et al. (1975) reported that milk, UHT pasteurized at temperatures of 115.6°-157.2°C with a holding time of 0.02 sec, exhibited higher starter activity in comparison with vat-pasteurized milk.

The production of flavor by yogurt cultures is a function of time as well as the sugar content of yogurt mix. Gorner et al. (1968) reported that acetaldehyde production in yogurt takes place predominantly in the first 1-2 hr of incubation. Eventually, 23-55 ppm of acetaldehyde is found in yogurt.

Hamdan et al. (1971) reported acetaldehyde levels of 22-26 ppm in their cultures at the fifth hour of incubation, and the acetaldehyde level declined in later stages of incubation. Yogurt flavor is typically ascribed to the formation of lactic acid, acetaldehyde, acetic acid, and diacetyl.

The milk coagulum during yogurt production results from the drop in pH due to the activity of the yogurt culture. The streptococci are responsible for lowering the pH of a yogurt mix to 5.0-5.5 and the lactobacilli are primarily responsible for further lowering of the pH to 3.8-4.4.

Attempts have been made to improve the viscosity and to prevent syneresis of yogurt by including a slime producing strain of Streptococcus filant or Streptococcus lactis var. hollandicus. The texture of yogurt tends to be coarse or grainy if it is allowed to develop firmness prior to stirring or if it is disturbed at pH values higher than 4.6.

Rennet addition to yogurt mix, excessive whey solids, and incomplete blending of mix ingredients are additional causes of a coarse texture. Homogenization treatment and high fat content tend to favor smooth texture. Gassiness in yogurt may be attributed to defects in starters or contamination with spore-forming Bacillus species, coliform, or yeasts, producing excessive CO2 and hydrogen.

In comparison with plate heat exchangers, cooling with tube type heat exchangers causes less damage to yogurt structure. Further, loss of viscosity of yogurt may be minimized by well-designed booster pumps, metering units, and valves involved in yogurt packaging.

The pH of yogurt during storage continues to drop. Gavin (1966) noticed a drop from 4.62 to 4.15 in 6 days of storage at 4°C. High temperatures of storage accelerate the drop in pH. Most yogurt manufacturers incorporate 5-7% sucrose in their yogurt mix prior to culturing.

Tramer (1973) reported that various strains of yogurt cultures responded differently to various levels of sucrose. No inhibition of culture activity was noticed up to 5.5% sucrose concentrations. At higher sucrose levels, acid production by some yogurt cultures was partially inhibited.

This effect was primarily ascribed to a stress on lactobacilli and was related to a total solids level in yogurt. Total solids, consisting of milk solids and sweeteners, above 22% level were inhibitory to Lactobacillus bulgaricus. The inhibition of yogurt culture is also caused by antibiotic residues in milk.

Mocquot and Hurel (1970) reported that both Streptococcus thermophilus and Lactobacillus bulgaricus are affected by 0.005 IU penicillin/ml, 0.066 μg aureomycin/ml and 0.38 IU streptomycin/ml. Streptococcus thermophilus is exceedingly sensitive to penicillin. It is affected at 0.01 IU/ml and acid production ceases at 0.03 IU/ml.

Phages are not a practical threat to yogurt making if using frozen cultures and their proper rotation are practiced along with high sanitation standards in the plant. However, phages for yogurt cultures have been isolated. Hypochlorites and quaternary ammonium compounds also inhibit yogurt cultures.

Heat treatment at 85°C for 30 min or equivalent is an important step in manufacture. The heat treatment (a) produces a relatively sterile medium for the exclusive growth of the starter, (b) removes air from the medium to produce a more conducive medium for microaerophilic lactic cultures to grow, (c) effects thermal breakdown of milk constituents, especially proteins, releasing peptones, sulfhydryl groups which provide nutrition and anaerobic conditions for the starter, and (d) denatures and coagulates milk albumins and globulins which enhance the viscosity and produce custard like consistency in the product. Homogenization also aids in texture development and additionally it alleviates the surface creaming and wheying off problems. Ionic salt balance in milk is also involved in the wheying off problem.

4. Manufacturing Procedures of Yogurt:

Plain Yogurt:

The steps involved in the manufacture of set-type and stirred-type plain yogurts. Plain yogurt normally contains no added sugar or flavors in order to offer the consumer natural yogurt flavor for consumption as such or an option of flavoring with other food materials of the consumer’s choice.

In addition, it may be used for cooking or for salad preparation with fresh fruits or grated vegetables. The fat content may be standardized to the levels preferred by the market. Also, the size of package may be geared to the market demand. Wax coated cups as well as plastic cups and lids are the chief packaging materials used in the industry.

Fruit Flavored Yogurt:

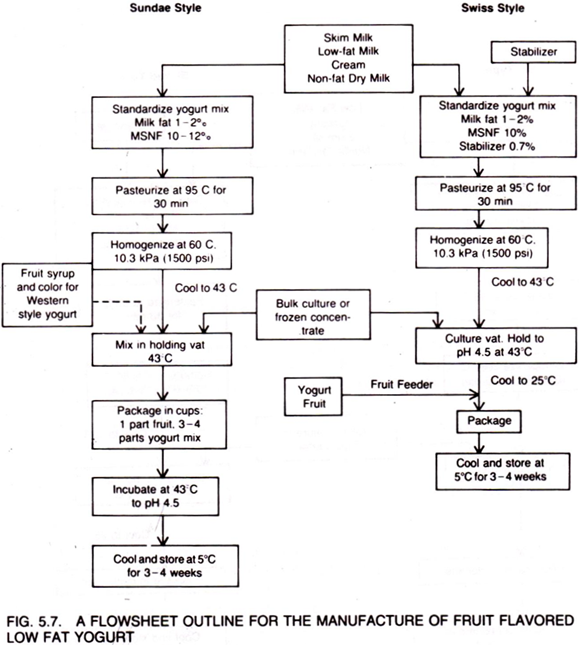

A general manufacturing outline tor both Sundae Style and Swiss yogurts is presented in Fig. 5.7. Several variations of this procedure exist in the industry. Fruit incorporation is conveniently effected by the use of a fruit feeder at a 15-20% level. Prior to, packaging, the stirred-yogurt texture can be made smoother by pumping it through a valve or a stainless steel screen.

The incubation times and temperatures are coordinated with the plant schedules. Incubation temperatures lower than 40°C in general tend to impart a slimy or sticky appearance to yogurt. Lactobacillus acidophilus culture concentrates may be incorporated into yogurt after incubation to make acidophilus yogurt, but the viability of the L. acidophilus cultures may be rather limited.

Wilcox (1971) reviewed the processes for making yogurt with polyunsaturated corn oil, instant yogurt, and yogurt enriched with vitamin C.

Post-Culturing Heat Treatment:

The shelf life of yogurt may be extended by heating yogurt after culturing to inactivate the culture and the constituent enzymes. Heating to 60°-65°C stabilizes the product so the yogurt shelf life will be 6-8 weeks at 12°C. However, this treatment destroys the “live” nature of yogurt, which may be a desirable consumer attribute to retain.

The proposed federal standards permit the thermal destruction of viable organisms with the objective of shelf life extension, but the parenthetical phrase “heat treated after culturing” must show on the package following the yogurt labeling. The post-ripening heat treatment may be designed to accomplish two objectives- (1) to ensure destruction of starter bacteria, contaminating organisms, and enzymes, and (2) to preserve or redevelop the texture and body of the yogurt by appropriate stabilizer and homogenization processes, similar to hot-pack cultured cream.

5. Manufacturing of Frozen Yogurt:

Soft-serve yogurt, hard-pack yogurt, and novelty items based upon yogurt are relatively new products getting “an enthusiastic response by the consumer. Push-ups, frozen yogurt on a stick, skippy cups, and tetrapaks are being manufactured and marketed.

The frozen yogurt base mix may be manufactured in a cultured dairy plant and shipped to a soft-serve operator or an ice cream plant. Alternatively, the mix may be prepared and frozen in an ice cream plant. The following formulation is generally used- 1.5-2.0% milk fat, 13-15% milk solids-not-fat, 0.15-0.20% gelatin (250 Bloom), 7-10% sucrose, and 4-5% corn syrup solids (24-26 DE).

These ingredients (except one-half of the sugar) are standardized in a blend tank and pasteurized at 88°C for 40 min. The mix is then homogenized at 58°-63°C at 10.3 kPa, and cooled to 44°C. Yogurt culture is then inoculated and incubation of the mix is continued until pH 3.9 is attained.

The yogurt mix is then cooled to 25°C and the remaining sugar as well as fruit is blended. Special fruit preparations designed for frozen yogurts are used at a level of 15-20%. This mix is then frozen in an ice cream freezer at 50-60% overrun, packaged, and hardened similar to ice cream. To obtain a soft-serve product, a soft-serve freezer is used at a draw temperature of -8°C.

6. Yogurt Quality Control:

Quality control programs for yogurt manufacture include control of product flavor, body and texture, color, process, and composition. The flavor defects are generally described as too intense, too weak, or unnatural. The sweetness level may be excessive, weak, or may exhibit corn syrup flavor. The flavor may be too tart, weak, or atypical. The ingredients used may impart undesirable flavors like stale, metallic, old ingredients, oxidized, rancid, or unclean. Lack of control in processing procedures may cause overcooked, caramelized, or too tart flavors. Proper control of processing parameters and ingredient quality ensures good flavor.

In hard-pack frozen yogurt, a coarse and icy texture may be caused by the formation of ice crystals due to fluctuations in storage temperature. Sandiness may be due to lactose crystals resulting from too high levels of milk solids or whey solids. A soggy or gummy defect is caused by too high milk solids-not-fat level or too high sugar content. A weak body results from too high overrun and insufficient total solids.

Color defects may be caused by the lack of intensity or authenticity of hue and shade. Proper blending of fruit purees and yogurt mix is necessary for uniformity of color. The compositional control tests are- fat, moisture, pH, and overrun (for frozen yogurt), and microscopic examination of yogurt culture to ensure a ratio of 1:1 in Lactobacillus bulgaricus and Streptococcus thermophilus.

Good microbiological quality of all ingredients is necessary. As a guideline, raw milk and cream should contain fewer than 500,000 and 800,000 bacteria/ml, respectively. The total bacteria count of pasteurized fluid dairy products should not exceed 50,000 counts/g or ml. Coliform counts for pasteurized products should not exceed 10/g or ml. Also, periodic checks for yeast and mold counts in fruit preparations are useful.