In this article we will discuss about:- 1. Chloroplast Engineering for Insect Resistance 2. Chloroplast Engineering for Pathogen Resistance 3. Chloroplast Engineering for Herbicide Resistance 4. Engineering Chloroplast for Biopharmaceutical Production 5. Engineering Chloroplast for the Production of Edible Vaccine 6. Engineering Chloroplast for Polyster Production and Others.

Chloroplast Engineering for Insect Resistance:

Since most of the chloroplast genes are transcribed as polycistronic RNA and subsequently processed to form individual proteins. The chloroplast transformation has definite advantage over its counterpart nuclear mRNA, which are monocistronic. This poses a series drawbacks when engineering multiple genes.

Deployment of multiple genes into nuclear genome is time consuming and requires introduction of first gene and back crossed to another transgenic plant. This has been enforced for the production of β-carotene expression and antibody production.

Engineering of chloroplast genome may result in higher expression level of transgene. High toxin production in transgenic plants was found to be indispensable for reducing resistance level in insects. Nuclear transgenic crops expressing Bacillus thuringeinsis (Bt) toxin has created concerned due to sub optimal production of toxin, consequently resulted in increased risk of Bt resistance.

Transgenic tobacco leaves expressing CryA a2 protoxin in chloroplast were fed to suscesptible bud worm and beet army worm, nearly 100% mortality was observed against all insect species. Successful and stable integration of CryAa2, due to its protoxin and small size (65 kD) in nature into all chloroplast genome was confirmed in transplastomic plants.

Expression of prokaryotic origin Bt Cry2Aa2 operon in plant chloroplast is a classic example of feasibility of multigene operon expression in engineered chloroplast. In addition, proper folding of Cry2Aa2 is also added by plastid encoded putative chaperone and facilitates large scale production of foreign protein in chloroplast i.e., upto the level of 45% of the total soluble proteins.

This is the highest level of foreign gene expressed ever reported in transgenic plants. Cry2Aa2 was chosen due to its toxicity to wide range of insects and low levels of cross- resistance against Cry1-A resistant insects and its expression as a protoxin.

Chloroplast Engineering for Pathogen Resistance:

Chloroplast genome can be engineered to produce novel foreign peptides to combat bacterial and fungal pathogens. Several peptides have been shown to exhibit antimicrobial properties. Recently, a synthetic antimicrobial peptide known as MS1-99 was expressed in chloroplast of tobacco plants. Antimicrobial MS1-99 is an amphipathic α-helical molecule exhibit high affinity for the negatively charged phospholipids found in outer membrane of bacteria and fungi.

When peptide come in contact with this membrane, individual peptide tends to aggregate to form pores and consequently leads to bacterial cell death by complete lysis. Transgenic plants expressed this peptide in chloroplast at high level of upto 21.5% of the total soluble protein and provide protection against Pseudomonas syringae, a major plant pathogen. Similarly, leaf extraction from these transgenic plants suppresses the growth of germinal spores of certain fungal species.

The same MSI-99 was also tested against Pseudomonas aeruginosa, multidrug resistant cause’s respiratory infections. Almost 96% of growth inhibitor takes place in in vitro experiment using cell-free extract of chloroplast transgenic plants and provided that MSI-99 has the potential to be an alternative to current antibiotic treatment and chloroplast proved as biological factories for the production of these novel antimicrobial peptides.

Chloroplast Engineering for Herbicide Resistance:

Most commonly used herbicide, glyphosate, used to eliminate weeds cannot distinguish weeds from crop plants. The lack of herbicide selection can be effectively handled by engineering crop plants for resistance to glyphosate herbicide. However, this approach raises serious concern about horizontal transfer of herbicide tolerant gene, escaped from pollen grain, which may result in super weeds or genetic pollution.

Introduction of herbicide resistant genes into the chloroplast genome can overcome series environmental concern by nuclear transgenic system. Selection of chloroplast genome for herbicide resistance is because plastid DNA is lost during pollen maturation and hence is not transferred to next generation during pollination process.

The transgenes are, however, maternally inherited. The chloroplast genome has been targeted for engineer to express petunia EPSPS nuclear gene and agrobacterium EPSPS gene for higher level of glyphosate resistant plants. While control plants were extremely sensitive to glyphosate, transgenic plants survived spray of high concentration of glyphosate (Fig. 19.5).

Integration of EPSPS gene into the chloroplast was conferred by southern blot analysis. The exact copy number of the integrated EPSPS gene was determined by establishing homoplasmy for the transgenic chloroplast genome. An estimation of 5,000 to about 10,000 copies of the integrated foreign EPSPS genes per cell.

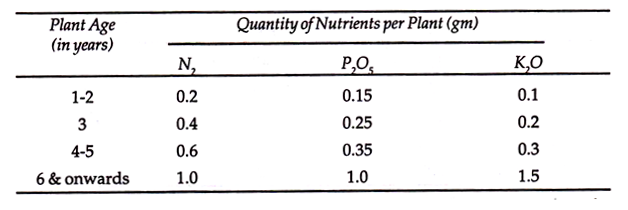

Several insertional sites have been identified in many plants chloroplast (Table 19.2). In tobacco plastids, engineering strategy resulted in 250 fold high level of glyphosate resistant C4 protein than were accomplished in nuclear transformation. Similarly, transgenic tobacco expressing bar genes in a chloroplast genome exhibits high level tolerance to phosphinothricin (PAT) and no pollen transmission of transgene was detected.

Engineering Chloroplast for Biopharmaceutical Production:

In recent years, chloroplast has been targeted for the production of variety of biopharmaceuticals, particularly human proteins. Due to their low expression in nuclear transformed plants, chloroplast offers a novel candidate for over production of foreign proteins. Chloroplasts are not only able to produce foreign proteins but also show significant potential in processing of eukaryotic proteins, including folding and formation of disulphide linkage. This inturn cut down the cost of expensive in vitro processing after their extraction. There has been estimated over 60% of the total production cost of human insulin is due to in vitro processing.

Chloroplast has been used to produce human therapeutic proteins like somatotropin (hsT), used in the treatment of dwarfism, and chronic renal failure. High level expression of hsp has been reported by researchers at Monsanto Company. The tobacco chloroplast accumulates between 0.2 to 7% of the total soluble proteins. This is almost 300 times greater than the production of same protein using nuclear transgenic plants. Similarly, transgenic tobacco accumulates high level of Human Serum Albumin (HSA) inspite of its extreme susceptible to proteolytic degradation.

Expression of HSA in transgenic chloroplast using Shine-Dalgarno Sequence (SD), which usually facilitates hyper-expression of transgenes, increased upto eleven percent after only 0.02% modification of HSA regulatory sequence. Accumulation of HSA in transgenic chloroplast is between 0.02 to 11% of total soluble proteins expressed in transgenic chloroplast, and also its accumulation level of 500 times higher than production in nuclear transgenic plants.

Inventer from leading Capitol Company (chlorogen) adapted chloroplast technology. Chlorogen Inc maintained that tobacco chloroplast holds potential candidate for high quality inexpensive production of certain therepeutic drug in future. Chlorogen technology targeted for the production of human serum proteins, interferon, insulin and vaccines for anthrax. For details see www(dot)science blog(dot)com/community.

Engineering Chloroplast for the Production of Edible Vaccine:

Efficacy of vaccine production in plants through nuclear transgenic plants has been documented. Vaccine production through conventional and non-conventional (recombinant technology) method invariably involves cost of purification and contamination. Hence, vaccines with properly folded and functional biopharmaceutical can be delivered orally. Bioencapsulation of vaccine protein with all functional properties within a plant cells offer protection against degradation in human digestive system and successful delivery to the target tissues for the elicitation of immune response.

Strategies for the large scale production of vaccines for cholera, plague, using chloroplast compartment have already been endeavoured. The cholera toxin of Vibrio cholera (CTB) and B subunits of enterotoxin of E. coli (LTB) provides vaccine antigenes. Introduction of CTB gene into the tobacco chloroplast genome produces vaccine protein upto 4% of total soluble leaf protein.

It is almost more than 400 fold higher than producing in nuclear genome. Synthesis of CTB via chloroplast mediated, correctly folded, disulphide linkages are able to binds to the ganglioside (GM) receptor of intestinal membranes. Downstream recovery of pharmaceutical drug from transplastomic plants reduced not only its cost of production but also the potential for other foreign multimeric proteins to be properly expressed and assembled in transgenic chloroplast.

Engineering Chloroplast for Polyster Production:

Production of bioplastics (polyhydroxybutyrate, PHB) in bacterial fermenters is more costly than chemically synthesized polyethylene resulted in reduced usage and used only for special applications. Therefore, polyhydroxy alkoanate (PHA) production could be optimised efficiently by shifting bacterial biosynthesis pathway to chloroplast fatty acid metabolism.

Chloroplast often provides sufficient amount of starting materials for PHA production. Besides, expression of genes for bacterial PHB synthesis in plants reduced the risk of unwanted gene escape into the environment via pollen. In addition, site specific integration of transgene for PHB production in plastomes allows more predictable transformation and better expression.

Recently, hydroxybutyric acid was produced in tobacco following transformation under the control of plastid regulatory elements and PHB production was recorded upto 1.7%. The PHB contents exceeded values measured in previously reported transgenic plants. Atleast 70% of plants produced hydroxybutyric acid was evidenced as polymer with a molecular mass upto 2,500 kD.

Strategies for Optimizing Foreign Gene Expression in Chloroplast:

In order to optimize foreign gene expression in chloroplast, certain regulatory sequences have been analysed in chloroplast by fusion to reporter genes. Inclusion of chloroplast specific strong promoter as well as UTR sequences mediates RNA stability. Translation is a crucial control step in optimizing protein production.

It is evident that 3′ UTR sequence shows minimum effect on chloroplast gene translation for example; in the plastic production, expression of PHB pathway genes in chloroplast can be accelerated by using psbA promoter and psbA-UTR which confer very strong gene expression.

The plastid promoter and UTR from PsbA genes were fused to the phb operon. Expression is enhanced in the light and in particular some tissue specifications. Introduction of additional translation enhancing elements from bacteriophage T7 gene 10 leader sequences have been implicated.

This leader sequence enhances translation of foreign gene in bacteria and executes the same functions in every chloroplast. When G10 L sequence was engineered in chloroplast genome which result in 200 fold accumulation of herbicide tolerant EPSPS protein in transgenic lines (Table 19.4).

Similar modification of human serum albumin (HSA) regulatory sequence using chloroplast untranslated region (UTR) resulted hyper-expression of HSA from initial 0.02 to an exemplary level upto 11.1%, which is compensation for expression proteolytic degradation.

Transplastomics without Antibiotic Resistant Gene:

Genetic engineering of chloroplast requires the introduction of antibiotic resistance gene particularly for screening of transgenes. Generally, antibiotic resistant gene, aadA, used as selectable marker. The selectable aadA marker gene, which confer resistant to antibiotics spectinomycin and streptomycin.

Introduction of transgenes into the chloroplast genome amplifies the antibiotics resistance genes. Initially, it was presumed that post-biology of pollen- mediated movement of transgene from transplastomic Brassica napus to its wild relative B. napus. This hypothetical question was later disapproved in contrast to a nuclear encoded trait.

A plastid encoded trait will not be transmitted from crop to the weed through pollen. Similar protein synthesising machinery between chloroplast and bacteria may enhance the possibility of gene movement from plant to soil bacteria or gastrointestinal tract. Therefore, specialized strategies have been enforced to knock out risk associated aad-A antibiotic marker gene from the transgenic plants.

A more efficient approaches was developed for marker gene removal from the nucleus and uses of P1 phage CRE-lax P site-specific recombination system. According to the CRE-lax P site, the marker gene and the gene of interest are introduced into the plastid genome in the absence of CRE activity.

If marker gene is to be removed, a gene encoding a plastid targeted CRE site specific recombinase is introduced into the nucleus. It is then subsequently enter into plastids. CRE(cre) could be then introduced by subsequent Agrobacterium mediated transformation by crossing. The nuclear ere is then removed by segregation in the seed progeny.

Using chloroplast recombination that deletes the marker gene via engineered direct repeats. Investigations on Chlamydomonas reinhardii showed that it is possible to eliminate marker genes. Homologous recombination between two direct repeats flanking a selectable marker facilitates it to be removed under non selective growth conditions.

Encouraged by these results, extended this technology to tobacco and demonstrated the production of transplastomic plants free from aad A gene. While removing aadA gene, 4-9 kb insert composed of aad A flanked by bar and aid A gene was transformed into plastid DNA and screened to remove wild type plastid genome.

Excision of aadA and uidA mediated by two 174 bp direct repeats aadA free to transplastomic plants containing the bar gene, which confer resistance to herbicide glufosinate. Marker free transgenic plants containing uid reporter gene was obtained by three 418, bp direct repeats allowed the removal of aadA and bar gene. Recently, another strategy to eliminate selectable marker gene has been developed using to P1 bacterial phage CRE-lox site specific recombination system.

Transplastomic Tobacco — A Case Study-1:

Tobacco is the fruitfly of plant research and its chloroplast genome has been identified as suitable candidates for hyper expression of suitable target genes. Tobacco produces millions of seeds per plants and undergoes maturation within three month. Therefore, it holds the potential and inexpensive host for variety of human biopharmaceutical proteins. In addition, most of the basic and applied research has been done using tobacco chloroplast.

Tobacco chloroplast has been used for the production of vaccines for various diseases like hepatitis, cholera and plague. Introduction of insect resistant plant by hyper expression of cry 2Aa2 gene in tobacco chloroplast resulted in 100% mortality in susceptible insects.

Tobacco chloroplast genome has also been demonstrated to engineer in the production of antibiotic marker free transplastomic plants. Therefore, tobacco chloroplast is being one of the model plants for all kinds of genetic modifications (Fig. 19.6).

Note:

(a) Plastid vector target inhibition of marker gene (M) and gene of interest (gal)

(b) Plastid targeted CRE is expressed from a nuclear gene excises flaxed by marker gene to yield T2-marker free transplastome.

Transplastomic Maize — A Case Study-2:

The remarkable success in the field of tobacco chloroplast for the hyper expression of pharmaceutical proteins has been extended to maize plant. Maize (Zea mays) is one of the most important cereal crops in the world. Presently, maize chloroplast genome has been targeted for the introduction and hyper expression of variety of marker and reporter genes. In the maize plastid transformation strategy flanking sequences (trn 1 and trn A) were amplified.

To engineer maize chloroplast genome maize calli were bombarded with chloroplast expression vector containing green fluorescent protein (GFP) and the betaine aldehyde dehydrogenase genes (BADH) as selectable markers. Several encouraging results show that chloroplast transformation of maize should provide a suitable avenue for the production of edible vaccines and oral delivery of biopharmaceuticals.