In this article we will discuss about:- 1. Meaning of Fermentor 2. History of Fermentors 3. Design 4. Construction 5. Use of Computer in Fermentor 6. Types.

Contents

Meaning of Fermentor:

A fermentor (bioreactor) is a closed vessel with adequate arrangement for aeration, agitation, temperature and pH control, and drain or overflow vent to remove the waste biomass of cultured microorganisms along-with their products.

A fermentor is used for commercial production in fermentation industries and is a device in which a substrate of low value is utilized by living cells or enzymes to generate a product of higher value. Fermentors are extensively used for food processing, fermentation, waste treatment, etc.

History of Fermentors:

De Beeze and Liebmann (1944) used the first large scale (above 20 litre capacity) fermentor for the production of yeast. But it was during the first world war, a British scientist named Chain Weizmann (1914-1918) developed a fermentor for the production of acetone.

Since importance of aseptic conditions was recognised, hence steps were taken to design-and construct piping, joints and valves in which sterile conditions could be achieved and manufactured when required.

For the first time, large scale aerobic fermentors were used in central Europe in the year 1930’s for the production of compressed yeast (de Becze and Leibmann, 1944). The fermentor consisted of a large cylindrical tank with air introduced at the base via network of perforated pipes.

In later modifications, mechanical impellers were used to increase the rate of mixing and to break up and disperse the air bubbles. This process led to the compressed air requirements. Baffles on the walls of the vessels prevented forming a vortex in the liquid. In the year 1934, Strauch and Schmidt patented a system in which the aeration tubes were introduced with water and steam for cleaning and sterilization.

The decision to use submerged culture technique for penicillin production, where aseptic conditions, good aeration and agitation were essential, was probably a very important factor in forcing the development of carefully designed and purpose-built fermentation vessels.

In 1943, when the British Govt. decided that surface culture was inadequate, none of the fermentation plants were immediately suitable for deep fermentation. The first pilot fermentor was erected in India at Hindustan Antibiotic Ltd., Pimpri, Pune in the year 1950.

Design of Fermentors:

All bioreactors deal with heterogeneous systems dealing with two or more phases, e.g., liquid, gas, solid. Therefore, optimal conditions for fermentation necessitate efficient transfer of mass, heat and momentum from one phase to the other. Chemical engineering principles are employed for design and operation of bioreactors.

A bioreactor should provide for the following:

(i) Agitation (for mixing of cells and medium),

(ii) Aeration (aerobic fermentors); for O2 supply,

(iii) Regulation of factors like temperature, pH, pressure, aeration, nutrient feeding, liquid level etc.,

(iv) Sterilization and maintenance of sterility, and

(v) Withdrawal of cells/medium (for continuous fermentors).

Modern fermentors are usually integrated with computers for efficient process monitoring, data acquisition, etc.

Generally, 20-25% of fermentor volume is left unfilled with medium as “head space” to allow for splashing, foaming and aeration. The fermentor design varies greatly depending on the type and the fermentation for which it is used. Bioreactors are so designed that they provide the best possible growth and biosynthesis for industrially important cultures and allow ease of manipulation for all operations.

Size of Fermentors:

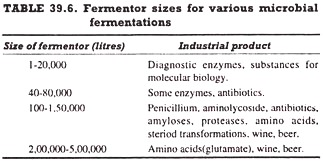

The size of fermentors ranges from 1-2 litre laboratory fementors to 5,00,000 litre or, occasionally, even more, fermentors of upto 1.2 million litres have been used. The size of the fermentor used depends on the process and how it is operated. A summary of fermentor or size of fermentor (litres) Industrial product sizes for some common microbial fermentations is given in Table 39.6.

Construction of Fermentors:

Industrial fermentors can be divided into two major classes, anaerobic and aerobic. Anaerobic fermentors require little special equipment except for removal of heat generated during the fermentation process, whereas aerobic fermentors require much more elaborate equipment to ensure that mixing and adequate aeration are achieved.

Since most industrial fermentation process are aerobic, the construction of a typical aerobic fermentor (Fig. 39.1) is the following:

1. Cooling Jacket:

Large-scale industrial fermentors are almost always constructed of stainless steel. A fermentor is a large cylinder closed at the top and the bottom and various pipes and valves are fitted into it. The fermentor is fitted externally with a cooling jacket through which steam (for sterilization) or cooling water (for cooling) is run.

Cooling jacket is necessary because sterilization of the nutrient medium and removal of the heat generated are obligatory for successful completion of the fermentation in the fermentor. For very large fermentors, insufficient heat transfer takes place through the jacket and therefore, internal coils are provided through which either steam or cooling water is run.

2. Aeration System:

Aeration system is one of the most critical part of a fermentor. In a fermentor with a high microbial population density, there is a tremendous oxygen demand by the culture, but oxygen being poorly soluble in water hardly transfers rapidly throughout the growth medium.

It is necessary, therefore, that elaborate precautions are taken using a good aeration system to ensure proper aeration an oxygen availability throughout the culture. However, two separate aeration devices are used to ensure proper aeration in fermentor. These devices are sparger and impeller.

The sparger is typically just a series of holes in a metal ring or a nozzle through which filter-sterilized air (or oxygen-enriched air) passes into the fermentor under high pressure. The air enters the fermentor as a series of tiny bubbles from which the oxygen passes by diffusion into the liquid culture medium.

The impeller (also called agitator) is an agitating device necessary for stirring of the fermenter.

The stirring accomplishes two things:

(i) It mixes the gas bubbles through the liquid culture medium and

(ii) It mixes the microbial cells through the liquid culture medium. In this way, the stirring ensures uniform access of microbial cells to the nutrients.

The size and position of the impeller in the fermentor depends upon the size of the fermentor. In tall fermentors, more than one impeller is needed if adequate aeration and agitation is to be obtained. Ideally, the impeller should be 1/3 of the fermentors diameter fitted above the base of the fermentor. The number of impeller may vary from size to size to the fermentor.

3. Baffles:

The baffles are normally incorporated into fermentors of all sizes to prevent a vortex and to improve aeration efficiency. They are metal strips roughly one-tenth of the fermentors diameter and attached radially to the walls.

4. Controlling Devices for Environmental Factors:

In any microbial fermentation, it is necessary not only to measure growth and product formation but also to control the process by altering environmental parameters as the process proceeds. For this purpose, various devices are used in a fermentor. Environmental factors that are frequently controlled includes temperature, oxygen concentration, pH, cells mass, levels of key nutrients, and product concentration.

Use of Computer in Fermentor:

Computer technology has produced a remarkable impact in fermentation work in recent years and the computers are used to model fermentation processes in industrial fermentors. Integration of computers into fermentation systems is based on the computers capacity for process monitoring, data acquisition, data storage, and error-detection.

Some typical, on-line data analysis functions include the acquisition measurements, verification of data, filtering, unit conversion, calculations of indirect measurements, differential integration calculations of estimated variables, data reduction, tabulation of results, graphical presentation of results, process stimulation and storage of data.

Types of Fermentor:

The fermentor (bioreactor) types used extensively in industries are the stirred tank fermentor, airlift fermentor, and bubble column fermentor.

(i) Stirred Tank Fermentor:

Stirred tank fermentors consists of a cylindrical vessel with a motor driven central saft that supports one or more impellers.

(ii) Airlift Fermentor:

In airlift fermentor (Fig. 39.2) the liquid culture volume of the vessel is divided into two interconnected zones by means of a baffle or draft tube. Only one of the two zones is sparged with air or other gas and this sparged zone is known as the riser.

The other zone that receives no gas is called down-comer. The bulk density of the gas-liquid dispersion in the gas-sparged riser tends to be lower than the bulk density in the down-comer, consequently the dispersion flows up in the riser zone and down-flow occurs in the down-comer.

Airlift fermentors are highly energy-efficient and are often used in large-scale manufacture of biopharmaceutical proteins obtained from fragile animal cells. Heat and mass transfer capabilities of airlift reactors are at least as good as those of other systems, and airlift reactors are more effective in suspending solids than are bubble column fermentors.

All performance characteristics of airlift -fermentor are related ultimately to the gas injection rate and the resulting rate of liquid circulation. Usually, the rate of liquid circulation increases with the square root of the height of the airlift device.

Because the liquid circulation is driven by the gas hold-up difference between the riser and the down-comer, circulation is enhanced if there is little or no gas in the down-comer. All the gas in the down-comer comes from being entrained in with the liquid as it flows into the down-comer from the riser near the top of the reactor.

(iii) Bubble Column Fermentor:

A bubble column fermentor (Fig. 39.3) is usually cylindrical with an aspect (height-to-diameter) ratio of 4-6. Gas is sparged at the base of the column through perforated pipes, perforated plates, or sintered glass or metal micro-porous spargers.

O2transfer, mixing and other performance factors are influenced mainly by the gas flow rate and the rheological properties of the fluid. Internal devices such as horizontal perforated plates, vertical baffles and corrugated sheet packing’s may be placed in the vessel to improve mass transfer and modify the basic design.

The column diameter does not affect its behaviour so long as the diameter exceeds 0.1 m. One exception is the axial mixing performance. For a given gas flow rate, the mixing improves with increasing vessel diameter. Mass and heat transfer and the prevailing shear rate increase as gas flow rate is increased.