In this article we will discuss about the methods and procedures to manufacture cultured dairy products. Learn about:- 1. General Principles of Manufacturing Cultured Dairy Products 2. Sequence of Processing Stages in the Manufacture of Cultured Dairy Products 3. Manufacturing of Cultured Buttermilk 4. Manufacturing of Cultured Cream and Few Other Details.

Contents:

- General Principles of Manufacturing Cultured Dairy Products

- Sequence of Processing Stages in the Manufacture of Cultured Dairy Products

- Manufacturing of Cultured Buttermilk

- Manufacturing of Cultured Cream

- Manufacturing of Acidophilus Milk

- Manufacturing of Kefir

- Manufacturing of Koumiss

- Manufacturing of Cream Cheese

- Direct Acidification Processes for Production of Soured Dairy Products

1. General Principles of Manufacturing Cultured Dairy Products:

Cultured dairy products are produced in various parts of the world from the milk of several species of mammals. The animals include- cow (Bos taurus), water buffalo (Bubalus bubalis), goat (Capra hircus), sheep (Ovis aries), mare (Equus cabalus), and sow (Sus scrofa).

The composition of these milks as presented by Jenness (1974). Since the total solids in milk of various species range from 11.2 to 19.3%, the cultured products derived from them vary in consistency from a fluid to custard like gel.

The range in casein content also contributes to the gel formation since upon souring this class of proteins coagulates at its isoelectric point of pH 4.6. The whey proteins are considerably denatured and insolubilized by heat treatments prior to culturing. The denatured whey proteins are also precipitated along with caseins to exert influence on the water binding capacity of the gel.

In the United States, bovine milk is practically the only milk employed in the industrial manufacture of cultured dairy products. For optimum culture growth, the raw materials must be free from culture inhibitors like antibiotics, sanitizing chemicals mastitis milk, colostrum, and rancid milk.

Microbiological quality should be excellent for developing the delicate and clean flavor associated with top quality cultured dairy products. The raw materials generally include whole milk, skim milk, condensed skim milk, nonfat dry milk, and cream In addition, other Sod materials like sweeteners, stabilizers, flavors, fruit preparation, and salt are required as components of certain cultured dairy foods. These materials are blended together in proportions to obtain a standardized mix conforming to the particular product to be manufactured.

A cultured dairy product plant requires a special design to minimize contamination of the products with phage and spoilage organisms. Filtered air is useful in this regard. In some locations, water may require special treatment including filtration to control chemical and microbiological contamination of cottage cheese curd during washing of the curd.

The plant is generally equipped with a receiving room to receive, meter or weigh and store milk and other raw materials. In addition, a culture propagation room along with a control laboratory, a dry storage area, a refrigerated storage area, a processing room, and a packaging room form the backbone of the plant.

The processing room contains equipment for standardizing and separating milk, pasteurizing and heating, and homogenizing along with the necessary pipelines, fittings, pumps, valves, and controls. For cottage cheese manufacture, the equipment consists of cheese vats with mechanical agitation devices, cutting knives, whey draining, curd washing, and creaming systems.

A control laboratory is generally set aside where culture preparation, process control, product composition, and shelf life tests may be carried out to ensure adherence to regulatory and company standards. Also, a quality control program is established by laboratory personnel.

A utility room is required for maintenance and engineering services needed by the plant. The refrigerated storage area is used for holding fruit, finished products, and other heat-labile materials. A dry storage area at ambient temperature is primarily utilized for temperature-stable raw materials and packaging supplies.

The sequence of stages of processing milk in a dairy plant is described by Jones and Harper (1976).

2. Sequence of Processing Stages in the Manufacture of Cultured Dairy Products:

1. Milk Procurement from the Farm:

Sanitary production of milk from healthy cows is necessary. For microbiological control, refrigerated bulk milk tanks should cool to 10°C in 1 hr and <5°C in 2 hr. Avoid unnecessary agitation to prevent lipolytic deterioration of milk flavor. Milk pickup is in insulated tanks at 48 hr intervals.

2. Milk Reception and Storage in Manufacturing Plant:

Temperature of raw milk at this stage should not exceed 10°C. Insulated or refrigerated storage up to 72 hr helps in raw material and process flow management. Quality of milk is checked and controlled.

3. Centrifugal Clarification and Separation:

Leucocytes and sediment are removed. Milk is separated into cream and skim milk or standardized to desired fat level at 5° or 32°C.

4. Mix Preparation:

Various ingredients to secure desired formulation are blended together at 50°C in a mix tank equipped with powder funnel and an agitation system.

5. Heat Treatment:

Using plate heat exchangers with regeneration system, milk is heated to temperatures of 85°-95°C for 10-40 min, well above pasteurization treatment. Heating of milk kills contaminating and competitive microorganisms, produces growth factors by breakdown of milk proteins, generates micro-aerophilic conditions for growth of lactic organisms, and creates desirable body and texture in the cultured dairy products.

6. Homogenization:

Mix is passed through extremely small orifice at pressure of 10.3-13.7 kPa, causing extensive physicochemical changes in the colloidal characteristics of milk. Consequently, creaming during incubation and storage of cultured dairy products is prevented. The stabilizers and other components of a mix are thoroughly dispersed for optimum textural effects.

7. Inoculation and Incubation:

The homogenized mix is cooled to an optimum growth temperature, depending upon the culture used. Inoculation is generally at the rate of 0.5-5% and the optimum temperature is maintained throughout incubation period to achieve a desired pH. Quiescent incubation is necessary for product texture and body development.

8. Cooling Fruit Incorporation, and Packaging:

The coagulated product is cooled down to 5°-22°C, depending upon the product. Using fruit feeder or flavor tank, the desired level of fruit and flavor is incorporated. The blended product is then packaged.

9. Storage and Distribution:

Storage at 5°C for 24-48 hr imparts in several products distribution desirable body and texture. Low temperature ensures desirable shelf life by slowing down physical, chemical, and microbiological degradation.

Milk is commonly stored in silos which are large vertical tanks with a capacity up to 100,000 liters. A silo consists of an inner tank made of Stainless steel containing 18% chromium, 8% nickel, and less than 0.07% carbon. Acid and salt resistance in the steel is attained by incorporating 3% molybdenum.

To minimize corrosion, this construction material is used for the storage of acidic products as well as those products containing added salt. The stainless steel tank is usually covered with 50-100 mm of insulation material which in turn is surrounded by an outer shell of stainless or painted mild steel or aluminum.

The silo tanks generally have an agitation system (60-80 RPM), spray balls mounted in the center for Cleaning in Place (CIP), an air vent, and a manhole. The air vent must be kept open during cleaning with hot cleaning solutions. This precaution is necessary to prevent a sudden development of vacuum in the tank and consequent collapse of the inner tank upon rinsing with cold water.

For reconstitution of dry powders, viz., nonfat dry milk, sweeteners, and stabilizers, the use of a powder funnel and recirculation loop, or a special blender is convenient.

The common pasteurization equipment consists of a vat, plate, triple- tube, scraped, or swept surface heat exchanger. Vat pasteurization is conducted at 63°C with a minimum holding time of 30 min. This temperature is raised to 66°C in the presence of sweeteners in the mix. For an HTST system, the equivalent temperature-time combination is 73°C for 15 sec or in the presence of sweeteners, 75°C for 15 sec. An UHT system employs temperatures greater than 90°C and as high as 148°C for 2 sec.

Alternatively, culinary steam may be used directly by injection or infusion to raise the temperature to 77°-94°C, but allowance must be made for an increase in water content of the mix due to steam condensation in this process. In some plants, steam volatiles are continuously removed by vacuum evaporation to remove certain undesirable odors (feed, onion, garlic) associated with milk.

The homogenizer is a high pressure pump forcing the mix through extremely small orifices. It includes a bypass for safety of operation. The process is usually conducted by applying pressure in two stages. The first stage pressure, ranging from 6.8 to 13.7 kPa, reduces the average milk fat globule diameter size from approx 4 μm (range 0.1 to 16 μm) to less than 1 p.m.

The second stage uses 3.4 kPa and is designed to break the clusters of fat globules apart with the objective of inhibiting creaming in milk. Culturing vats for the production of fermented dairy products are generally designed with a cone bottom to facilitate draining of relatively viscous fluids after incubation.

For temperature maintenance during the incubation period, the culturing vat is provided with a jacket for circulating hot or cold water or steam located adjacent to the inner vat containing the mix. This jacket is usually insulated and covered with an outermost surface made of stainless steel or aluminum or painted steel.

The vat is equipped with a heavy-duty, multi-speed agitation system, a manhole containing a sight glass, and appropriate spray balls for CIP cleaning. The agitator is often of swept surface type for optimum agitation of relatively viscous cultured dairy products. For efficient cooling after culturing, plate or triple-tube heat exchangers are used.

The culturing vat is designed only for temperature maintenance. Therefore, efficient use of energy requires that the mix not be heat treated in the culturing vat.

Most plants attempt to synchronize the packaging lines with the termination of the incubation period. Generally, textural defects in cultured products are caused by excessive shear during pumping or agitation. Therefore, positive drive pumps are preferred over centrifugal pumps for moving the product after culturing or ripening. For incorporation of fruit, it is advantageous to use a fruit feeder system adapted from the frozen dessert industry. Various packaging machines of suitable speeds are available to package various kinds and sizes of cultured dairy products.

3. Manufacturing of Cultured Buttermilk:

Cultured buttermilk is obtained from pasteurized skim milk or part skim milk cultured with lactic and aroma producing organisms. Streptococcus lactis and/or Streptococcus cremoris, Streptococcus lactis subsp. diacetylactis and Leuconostoc cremgris are frequent cultures.

The term buttermilk is also used for a phospholipid-rich fluid fraction obtained as a by-product during the churning of cream in butter manufacture. However, cultured buttermilk is viscous, cultured, fluid milk, containing a characteristic pleasing aroma and flavor.

Cultured buttermilk is usually produced in dairy plants processing milk and other fluid dairy products. It is packaged in traditional milk cartons.

The processes used in the manufacture of cultured buttermilk include pasteurization, homogenization, and culturing systems. The ingredients are skim milk, low-fat milk, cream, condensed skim milk, nonfat dry milk, culture, and salt. The addition of 0.20-0.25% sodium citrate to milk provides a precursor to enhance flavor production by the culture.

Butter flakes are also incorporated in certain markets. Milk fat level ranges from 0.5 to 1.8%; however, the proposed federal buttermilk standards call for a maximum milk fat content of 0.5% and a minimum of 8.25% milk solids-not-fat. The standards also require a minimum titratable acidity of 0.5% calculated as lactic acid. Characteristic flavor ingredients, nutritive carbohydrate sweeteners, stabilizers, and coloring which does not simulate the color of milk fat, may also be used.

Optionally, a minimum of 2000 International Units of vitamin A and 400 International Units of vitamin D per 0.95 liter (1 qt) of buttermilk may be added. The standards also define the products obtained from milk of various fat concentrations. Cultured milk shall be obtained from milk containing not less than 3.25% milk fat. Cultured low-fat milk shall contain not less than 0.5 or more than 2.0% milk fat.

For standardizing the milk solids-not-fat level to 8.25%, in addition to the traditional dairy ingredients, any milk-derived ingredient may be used. However, this ingredient should not decrease the protein milk solids-not-fat ratio and the protein efficiency ratio of the resulting mixture. Butter granules or flakes may be added to buttermilk either by churning 18-20% fat cream or by spraying melted butter oil on chilled buttermilk.

Under refrigeration, the keeping quality of cultured buttermilk is extended to 3-4 weeks. Wheying off may occur but can be avoided by using a suitable stabilizer and proper processing conditions. To increase the popularity of buttermilk, several attempts have been made to market fruit flavored cultured milk. However, commercial application has not been realized to any appreciable level.

The quality of buttermilk in the various regions of the country is not consistent. Kosikowski (1977), Babel (1976), and Emmons and Tuckey (1967) reported various factors causing quality problems. A proper buttermilk flavor is produced by maintaining high standards of sanitation, an active starter and a uniform temperature of 22°C. It is possible to improve the buttermilk flavor by the addition of citric acid, sodium citrate, sodium chloride, and/or cream.

Thin consistency, excessive CO2 production, unclean or putrid odor, and bitter taste may result from contamination of the culture, improper pasteurization, or poor sanitary practices in the plant. A certain amount of CO2 makes an important contribution to the desirable flavor of buttermilk. Metallic flavor can be avoided by the use of stainless steel or glass-lined equipment.

Development of too much acidity (>0.85% lactic acid) is generally checked by decreasing the amount of inoculum, by rapid cooling after ripening, or by blending pasteurized skim milk. Sharp acid flavor may be moderated by the addition of 0.1 – 0.2% sodium chloride. The fermentation period is important in flavor production and retention. Improper incubation times cause poor flavor in buttermilk, especially when citric acid is in limiting quantities.

Buttermilk possesses a characteristic fluidity. The viscosity of buttermilk is directly related to acidity. Some strains of Streptococcus cremoris produce thick-bodied buttermilk because of the tendency of the bacterial cells to form chains. Certain contaminants like Alcaligenes viscolactis may produce a ropy condition.

The chemical composition of milk also influences the viscosity of the product; higher total solids content produces a viscous product and lower total solids content results in thin-bodied buttermilk. A solids-not-fat content of 9% in skim milk is optimum for viscosity. Agitation of the product at an acidity of 0.85% lactic acid produces a good body. Ten percent re-constituted nonfat dry milk produces a very acceptable product.

Excessive agitation, high storage temperature, and contamination with proteolytic organisms yield relatively thinner buttermilk. The microbiological quality of milk is therefore critical in developing the flavor and the body of buttermilk. For this reason, the use of return milk for buttermilk manufacture is precluded.

Gelatin and fat may be incorporated to improve the body of buttermilk. Considerable foam may be produced in buttermilk if air is pumped into the product as a result of violent agitation or leaky pumps. For standardizing the viscosity of buttermilk produced from batch to batch, a viscometer may be used.

Buttermilk Defects and Possible Causes:

1. Flat, “‘Green”—Acidity too low, low setting temperature, low solids milk, lack of flavor organisms, short incubation period.

2. High Acid, Sour—Setting temperature too high, incubation time too long, lack of fat, inoculation too heavy, poor refrigeration of finished product.

3. Biting on the Tongue, “Carbonated”—Too many flavor organisms, over-ripening, contaminated culture.

4. Metallic—Contact with copper or iron, rusty equipment, high acidity and age.

5. Oxidized—Metal contamination, use of oxidized dairy products.

6. Rancid—Mixing homogenized milk with raw dairy products, use of rancid milk or cream.

7. Whey Off—Excessive agitation when warm, breaking at too low acidity, adding skimmed milk to reduce viscosity, low solids milk, high storage temperature, high setting temperature, too low or too high treatment of skim milk.

8. Lumpiness—High acidity, high setting temperature, poor agitation during breaking, low heat treatment of milk.

9. Thick, Heavy Body—High acidity, copy culture, solids too high, high incubation temperature, long incubation time, high heat treatment of milk, homogenization of high fat milk.

10. Thin, Light Body—Inactive culture, low setting temperature, low heat treatment of milk, low acidity, low solids, too much agitation during breaking.

11. Incorporated Air, Foamy—Agitation too vigorous, pumping with centrifugal pump, leaky pumps, or valves.

4. Manufacturing of

Cultured Cream:

Cultured cream or sour cream is manufactured by ripening pasteurized cream of 18% fat content with lactic and aroma-producing bacteria. This product resembles cultured buttermilk in terms of culturing procedure. However, in consistency it is an acid gel containing butter-like aromatic flavor. The federal standards stipulate a minimum titratable acidity of 0.5% lactic acid, a minimum fat of 18%, and a maximum stabilizer concentration of 0.1%. Additives permitted are standardizing flavors, stabilizers, and enzymes.

Cultured cream is used as a topping on vegetables, salads, fish, meats, and fruits, as a filling in cakes, and in soups and cookery in place of buttermilk or sweet cream. It can be dehydrated by spray drying and used as an ingredient wherever its flavor is needed.

The manufacturing method shown is a general procedure. Modifications in this process are available to suit certain purposes. Homogenization twice at 17.2 kPa and at 71°C has been used to produce a very thick product.

One might manufacture cultured cream in individual packs which may be filled before ripening or soon after the ripening stage, followed by cooling. A heavy-bodied product is formed on setting. Factors affecting viscosity of cultured cream are- (a) acidity, (b) mechanical agitation, (c) heat treatment, (d) solids-not-fat content, (e) rennet addition, and (f) homogenization. It is considered desirable to supplement cream containing solids- not-fat less than 6.8% with milk solids to increase viscosity. The HTST pasteurization produces a thin product as compared to the long hold, vat pasteurization method. Rennet addition in small quantities (0.5 ml single strength to 37.85 liters of cream) aids in thickening the product.

As in buttermilk, flavor may be improved by incorporating into cream 0.15- 0.20% sodium citrate, which is metabolized by Streptococcus lactis subsp. diacetylactis and Leuconostoc cremoris to produce more aroma compounds (diacetyl and volatile acids).

Guthrie (1963) reported that differences in the smoothness of cultured cream are related to differences in lactic cultures. Ropiness characteristic of a lactic culture enhances the smoothness and to some extent the viscosity of cultured cream. The body of the product appears to be independent of the culture used.

The hot-pack process ensures long shelf life by destroying the microorganisms and the enzymes present in the finished product. Packaging in a plastic or metal container with a hermetically sealed lid further ensures prevention of recontamination by microorganisms as well as protection from oxidative deterioration of milk fat in the finished product.

Cream used in the manufacture of cultured cream should be fresh with a relatively low bacterial count. During cream separation from milk, the bacteria tend to concentrate in the lighter phase, cream, thereby enhancing its vulnerability to spoilage. Pasteurization at 74°C for 30 min or at 85°C for 1 min is satisfactory from a bacteriological standpoint.

Artificial Cultured Cream:

This product may be defined as cultured cream in which part or all of the milk fat has been replaced by other oils or fats. Such a product is sold commercially in the United States. It appears to have advantages over conventional cultured cream in terms of price and caloric value. In this regard, a suitable product may be manufactured using a process identical to that for cultured cream with the exception of the starting material. An artificial cream may be prepared by emulsifying a suitable fat in either skim milk or in suspensions of casein compounds or soybean protein products. A suitable emulsifier, stabilizer, flavor, and color may be incorporated in the starting mix.

Sour Cream Dip:

Party dips based on sour cream are made by blending appropriate seasoning bases in cultured cream. By packaging under refrigerated conditions, the product has shelf life of 2-3 weeks under refrigerated storage. To build extra body and stability, 1-2% nonfat dry milk and 0.8-1.0% stabilizer are incorporated at 80°C.

The mixture is pasteurized by holding for 10 min, and homogenized at 17.2 kPa to re-suspend and smooth the product. The seasonings are blended at this stage while the mix is still at 80°C, followed by hot-packing in sealed containers. Upon cooling and storage at 5°C, partial vacuum inside the container assists in the prevention of oxidative deterioration to yield an extended shelf life of 3-4 months.

Sour Half and Half:

To satisfy the consumer demand for relatively low-fat and less expensive cultured cream substitutes, sour or cultured half and half has been developed commercially. It is manufactured from a mix containing a minimum of 10.5 and a maximum of 18% milk fat. To compensate for reduction in solids due to lower milk fat level, it is customary to increase the milk solids-not-fat level to 10-12%. Accordingly, a satisfactory body, viscosity, and texture are obtained.

The manufacturing principles for cultured half and half are similar to those for cultured cream except for the formulation of the initial mix Skim milk, cream, and other dairy ingredients are blended to a standard of 10 5% fat and 10-12% milk solids-not-fat. This mix is then processed along the same lines as cultured cream.

Salad Dressing:

Using sour half and half as a base, appropriate flavor bases may be blended to produce a distinctive creamy salad dressing. This dressing contains about 50-75% less calories than conventional salad dressings but has comparable flavor and texture. The reduction in calories is primarily due to the lower fat level 10.5% in sour half dressing as compared to 30-80% oil in regular dressing.

5. Manufacturing of

Acidophilus Milk:

Acidophilus milk is produced by fermentation of milk with Lactobacillus acidophilus. This product has been considered to possess therapeutic value, particularly following antibiotic therapy, and is therefore prescribed by dieticians and physicians for digestive disorders.

Its therapeutic properties are attributed to the ability of the organisms to become transplanted in the intestinal tract. Lactose (present in the fermented milk), in general, is a slowly assimilable disaccharide and is unchanged by the digestive process until it reaches the intestine where it is metabolized by Lactobacillus acidophilus to produce an acidic condition.

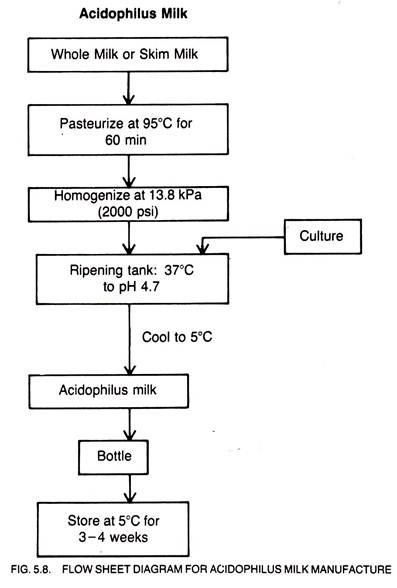

This condition discourages the growth and proliferation of gas-forming putrefactive organisms in the gut. Based on this reasoning, efforts have been made to produce a product containing a live culture of the strains that can be transplanted in the intestines. The manufacturing principle resembles buttermilk manufacture and is shown in Fig. 5.8.

Lactobacillus acidophilus is a slow fermenting organism and to get a reasonably fast growth rate it is customary to ultra-heat milk (98°C for 30 min or 145°C for 2-3 sec) before inoculation. For viability of the cells, it is preferable to terminate the incubation period when the acidity reaches 0.65%. Continued incubation may result in 1% or more acidity.

Acidophilus milk should be cooled to 5°C immediately. Fresh acidophilus milk contains in excess of 500 million cells/ml, although the viable count decreases rapidly with storage. The product obtained by fermentation may be too sour for many palates. For moderating the sour taste, acidophilus milk may be mixed with cultured buttermilk.

Alternatively, souring is controlled by using a mixed culture. Bioghurt is a trade name of a milk product fermented with Lactobacillus acidophilus and Streptococcus lactis. It belongs to a family of dairy products fermented by a mixture of organisms which are non-symbiotic, and nonspecific. One of the cultures is generally Lactobacillus acidophilus.

Several combinations of mixed starters are possible and one might employ two or more of the organisms generally utilized in the manufacture of cultured dairy products. Lactobacillus (Bifidobacterium) bifidus may also be utilized. The manufacturing process would be similar to yogurt manufacture with modifications according to the cultural conditions of the fermenting organisms. Apparently, it is possible to incorporate different levels of acidities and flavor by using the cultures in various combinations. This area of cultured dairy products needs further development.

Consumption of milk containing live Lactobacillus acidophilus cells has been facilitated by the recent introduction of uncultured low-fat milk inoculated with about 500 million acidophilus cells per ml. An acidophilus cell concentrate is prepared by centrifugation, suspended in regular refrigerated milk, and packaged. The product does not ferment as long as it is held under refrigeration during distribution and storage permitting the consumers to enjoy the sweet flavor of milk as well as inges live Lactobacillus acidophilus cells.

Campbell and Marshall (1975) mentioned a Japanese milk product containing an extract of Chlorella algae, vitamin C, and viable cells of Lactobacillus (Shirota strain) in excess of 108/ml. It is reported to have a pleasant mildly sour flavor and thin consistency. Lactobacillus casei has also been employed as a culture in fermented milk drinks.

6. Manufacturing of

Kefir:

Kefir belongs to the class of acid and alcoholic fermented milks Kefir is very popular in the USSAR with an animal per capita consumption of 4.5 kg (10 lb). It is produced by fermentation with kefir grains. The grains are white to yellow in color and insoluble in water and common solvents. However, when added to milk, their size expands by imbibing water and their color changes to white.

According to Kosikowski (1977) the grains contain 24% slimy polysaccharide secreted by the culture. The symbiotic microflora contains yeasts (Saccharomyces kefir and Torula kefir), lactobacilli (Lactobacillus caucasicus), leuconostocs, and lactic streptococci. The product is foamy and fizzy due to its CO2 content. An outline of kefir manufacturing principles is shown in Fig. 5.9.

Kefir grains are generally recovered and used repeatedly. For recovery the grains are sieved off after fermentation. They are either suspended in cold water and stored at 4°C or dried in cheesecloth at room temperature for 36-48 hr and stored dry at 4°C. The grains retain their activity for more than a year when stored dry and cold, but in water suspension they lose their activity after a week.

7. Manufacturing of

Koumiss:

Koumiss is similar to kefir except that mares’ milk is used in its manufacture. Russians use koumiss for the treatment of pulmonary tuberculosis in doses of 1.4 liters (3 pints) per day for 2 months. The product is alcoholic and produces slight intoxication. The alcohol content of koumiss may vary from 1 to 2.5%, depending upon whether the product is of the weak or strong type. Corresponding to the alcoholic content, the titratable acidity varies from 0.7 to 1.8% lactic acid. Mares’ milk is low in casein content and does not curdle like cows’ milk. Accordingly, koumiss is a grayish-white wholesome drink.

The starter for koumiss consists of Lactobacillus bulgaricus and lactose- fermenting yeast, Torulopsis holmii. Lactic acid, ethanol, and CO2 are the major products giving koumiss a sour alcoholic flavor and fizzy appearance. In certain cases of slow fermentation, horse flesh or tendon or some vegetable matter is added. Presumably, this practice provides the microbial flora needed for fermentation. A detailed description of koumiss production is provided by Kosikowski (1977).

In view of the production of CO2 in the product, appreciable pressure is developed in the capped bottles. In general, koumiss is quickly marketed. To satisfy the rising consumer demand in the U.S.S.R., koumiss is now being made from skimmed cows’ milk.

8. Manufacturing of

Cream Cheese:

Cream cheese contains at least 33% milk fat and not more than 55% moisture. Ingredients used are: cream, milk, skim milk, condensed milk, and nonfat dry milk. Cream cheese is manufactured by a cooked curd process similar to cottage cheese. Depending upon the plant schedule, the process may be the long set or short set type. Figure 5.12 shows the principles of cream cheese manufacture.

After the coagulum is formed, it is stirred and heated gradually to 54°C by direct addition of hot water or by indirect heating through a jacket. Whey separation may be conducted mechanically by specially designed centrifugal separators. Hot packing significantly extends the shelf life of the product. Product deterioration is generally due to the growth of yeasts and molds.

9. Direct Acidification Processes for Production of Soured Dairy Products:

Direct acidification is considered as an alternate method for the production of soured dairy products. In recent years increasing attention has been paid to the development of imitation cultured dairy products using this technique. This process eliminates the need for acid production by lactic starter cultures and an acid condition is generated in the product by the addition of a food-grade acid.

Stabilizers and artificial flavors are incorporated to simulate the body and flavor of a cultured dairy product. The base of directly acidified products may consist of dairy ingredients or may be an emulsified vegetable oil stabilized with sodium caseinate. The acids used are citric, phosphoric, gluconic, or lactic. Lactic acid is sparingly used because it is relatively expensive.

Glucono-delta-lactone hydrolyzes slowly in milk to form gluconic acid, simulating somewhat the rate of acid production by a lactic culture. The flavors containing diacetyl are generally derived from culture distillates. Among the stabilizers and emulsifiers are- vegetable gums, starch, carrageenan, gelatin, partial glycerides, casemates, and sodium phosphate.

The advantages claimed for direct acidification over conventional bacteriological souring include- (a) the process is easier to control- since lactic cultures are not involved, none of the problems associated with their usage (e.g., phage, antibiotic residues in milk) are encountered; (b) the process is quicker and more economical in terms of manpower; (c) it eliminates the need for expensive culturing vessels and is more economical on floor space; and (d) products of readily reproducible flavor can be made.

Buttermilk and sour cream are presently produced on a limited scale by direct acidification processes. According to the federal standards they must be labeled as “acidified” products. In the case of cottage cheese the label includes “directly set” or “curd set by direct acidification.”

Several developments have been recorded in the area of cottage cheese making by direct acidification. Deane and Hammond (1960) developed a process based on the principle of acidifying milk with neutral cyclic esters which hydrolyze in aqueous media to form organic acids. The most suitable acidifying agent for this purpose is D-glucono-delta-lactone, a neutral inner ester of gluconic acid. In milk the glucono-delta-lactone slowly hydrolyzes to form gluconic acid which reduces the pH of milk to the desired level of 4.5-4.7. The rate of hydrolysis of the glucono-delta-lactone is controlled by temperature. Higher temperature accelerates the rate. For economic reasons, this process is not commercialized.

Little (1968) patented a process using hydrochloric acid or phosphoric acid for lowering the pH of skim milk to 4.6 at 4°C and inducing coagulation with rennet. After cutting the curd, the cooking process is started. Corbin (1971) patented a process using a food-grade acid to lower the pH of skim milk to 5.0, followed by acidification with D-glucono-delta-lactone.

Wakeman’s patent (1972) utilizes direct acidification of milk at low temperature and induces the curd formation by quiescent heating. Kosikowski (1977) reviewed the use of acid whey powder as an acidulant in cultured dairy products. In addition, cottage cheese has been made from ultra-filtered skim milk, obtained by fractionation of milk with special membranes.

Continuous and automated processes for cottage cheese making are reviewed by Ernstrom and Kale (1975). They reported that the cultures contribute not only the acid but also a factor involved in developing desirable body and texture to cottage cheese curd. They recommended a combination of pre- culturing milk to pH 5.5 -5.7 with starter and direct acidification to achieve desirable moisture retention and firmness in cheese curd.

The cultured dairy products differ from acidified products in several constituents. They contain starter culture cells (several million/g), high enzymatic activity, and products derived by their action on lactose, milk fat, and proteins. Furthermore, they contain antibiotics produced by the starters. The significance of these differences in nutrition, if any, is not fully known.