Short Notes on Solid Substrate Fermentation!

There are certain fermentation processes that do not involve liquid medium. For these bio- technological processes, the growth of the microorganisms is carried out on solid substrates in the complete absence or almost complete absence of free water. The presence of some moisture (about 15%) is necessary for solid substrate (or solid state) fermentation (SSF).

The most commonly used solid substrates for SSF are cereal grains, wheat bran, sawdust, wood shavings and several other plant and animal materials. These solid substrates are polymeric in nature, insoluble or sparingly soluble in water, and contain concentrated source of nutrients for the growth of microorganisms.

SSF is a very old traditional technique carried out in many countries. It is used for the production of edible mushrooms, cheese, soy sauce and many other fermented products (including enzymes and organic acids). A selected list of solid state fermentations is given Table 19.2. Composting is a good example of SSF.

Solid substrate fermentation has been very popular for the production of fermented foods (idli, dosa, dhokla, bread, beverages, fermented fish, meat, yogurt, cheese, pickles). Fermentation often makes the food more nutritious, easily digestable and better in flavour. For solid substrate fermentation, single pure cultures, mixed cultures or mixed organisms may be used. Pretreatment of substrate raw materials is sometimes done to facilitate the availability of nutrients.

Solid substrate fermentation is normally carried out as a non-aseptic process. This saves sterilization costs. It is important that the substrates used in SSF have adequate spaces in between to allow good air circulation. This facilitates adequate exchange of gases, besides promoting heat elimination. Forced air circulation may be done to maintain optimal conditions in SSF.

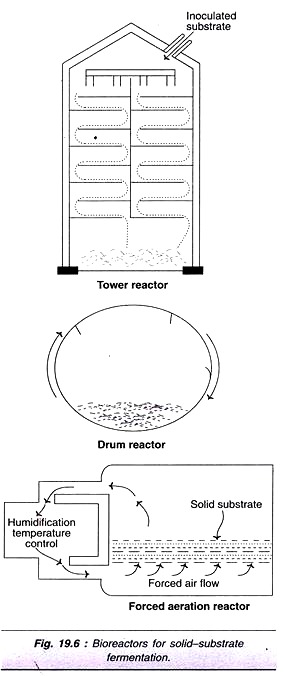

Bioreactors for SSF:

Bioreactors designed for solid state fermentation are much simpler compared to liquid-state fermentation. In the Fig 19.6, tower reactor, drum reactor and forced aeration reactor, used in SSF are depicted.

Advantages of SSF:

i. Solid substrate fermentation employs simple natural solids as the media.

ii. Low technology, low energy expenditure and requires less capital investment.

iii. No need for sterilization, less microbial contamination and easy downstream processing.

iv. Yield of the products is reasonably high.

v. Bioreactor design, aeration process, and effluent treatment are quite simple.

vi. Many domestic, industrial and agricultural wastes can be fruitfully used in SSF.

Limitations of SSF:

i. The microorganisms that tolerate only low moisture content can be used.

ii. Precise monitoring of SSF (e.g., O2 and CO2 levels, moisture content) is not possible.

iii. The organisms grow slowly and consequently there is a limitation in product formation.

iv. Heat production creates problems, and it is very difficult to regulate the growth environment.