The following points highlight the five main applications of microbes used in various fields. The applications are:- 1. Commercial Production of Compounds 2. Enzyme Technology 3. Pharmaceutical Industry 4. Sewage Treatment 5. Energy Generations.

Application # 1. Microbes and Commercial Production of Compounds:

Several important compounds are obtained from microorganisms such as yeasts and moulds.

These have been summarised in Tables 5:

1. Lactic Acid Production:

Carbohydrates such as corn and potato starch, molasses and whey can be used for the production of lactic acid. Let us understand lactic acid production from whey. Large quantities of whey are produced during the manufacture of dairy products such as cheese. Whey contains lactose, nitrogenous substances including vitamins and salts. Lactobacillus bulgaricus is a bacteria that can grow rapidly and is capable of converting lactose to lactic acid.

2. Vinegar Production:

The term vinegar is derived from the French term ‘vinaigre’ which means ‘sour wine’. Vinegar is prepared by allowing wine to get sour under controlled conditions.

The production of wine involves two types of biochemical changes:

a. Alcoholic fermentation of a carbohydrate by yeast

b. Oxidation of the alcohol to acetic acid by Acetobacter (i.e. acetic acid bacteria).

Depending on the carbohydrate used for fermentation, different types of vinegar are produced. The industrial process of vinegar production is known as Frings method (Fig. 2).

3. Amino Acid Production:

Microorganisms can synthesise amino acids from inorganic nitrogenous compounds. When the rate of synthesis exceeds the rate of need of the cell, the excess is secreted into the medium, which can then be extracted.

Lysine is produced using two species of bacteria namely E.coli and Enterobacter aerogenes in two steps. The first step involves the formation of DAP or Diaminopimelic acid in the presence of E.coli under controlled conditions of temperature, aeration and pH. During the second step, DAP carboxylase obtained from Enterobacter is added to the culture to convert DAP to lysine.

Lysine is an essential amino acid for humans and since cereal proteins are deficient in this amino acid, it is used as a supplement for bread and other food items, (dap)

Glutamic acid, is another amino acid produced in large amounts by Micrococcus, Arthrobacter sp. Glutamic acid is a condiment and a flavour enhancing agent in the form of monosodium glutamate.

Application # 2. Microbes and Enzyme Technology:

Enzymes are biological catalysts necessary to speed chemical reactions in a cell. This property of enzymes has significance, since it can be used to speed up industrially important reactions. Also enzymes are much more efficient than inorganic catalysts since they can function at room temperature. One more advantage of using enzymes is that they are substrate specific and produce pure products which are of significance in pharmaceutical, food and agricultural industries.

There are however certain disadvantages. Enzymes can be easily denatured by temperature and pH change and by organic solvents. They may also be inhibited by products of the reaction. They are expensive to produce and the choice of the organism is important since only non-pathogenic organisms should be used. About 200 enzymes are used and most of them are obtained from 11 species of fungi, 4 species of yeasts and 8 species of bacteria.

Microorganisms are better source of enzymes than plants and animals because of the following reasons:

a. They can be grown in bulk in fermenters under controlled conditions.

b. They have high growth rates.

c. They can be genetically engineered easily.

d. Mutants can be produced easily.

e. They are easier to maintain as the nutritional requirements are simpler. They can also be grown on cheap, waste substrates.

f. The quantity of enzymes produced is enormous and they are easier to recover and purify.

The different enzymes and its uses in different types of industry are summarised in Table 6. The enzymes obtained are used in pharmaceutical industry, cheese making, wine making, fruit juice and wine producers, detergent manufacturers, textile manufacturers, etc.

Immobilised Enzyme Technology:

In this technology, the enzyme is bound or immobilised on a material through which the

substance to be changed by the enzyme is passed. A variety of substances including paper, wood chips, glass beads and ceramic have been used to immobilise the enzymes.

The main advantages of this technique are as follows:

a. The enzymes can be used again and again.

b. The end products can be recovered in pure form.

Application # 3. Microbes and the Pharmaceutical Industry:

Compounds of pharmaceutical importance are synthesised by microbes.

Some important examples are briefly described below:

1. Insulin Production:

Insulin is a pharmaceutical important compound produced commercially by E.coli which is genetically engineered. In earlier times, insulin was isolated from the pancreatic tissue of animals. Human insulin gene is introduced into E.coli by recombinant DNA technology. The bacterium is grown in large quantities in cultures.

The insulin can be extracted, purified and is ready to use. The two main advantages of the insulin produced by the recombinant DNA technology are as follows – (1) it is chemically identical to human insulin, (2) it can be made available in unlimited quantities.

2. Penicillin Production:

The discovery of antibiotics and its commercial production represent one of the most dramatic case histories in the development of industrial microbiology. Penicillin was the first antibiotic to be produced by Alexander Fleming from Penicillium notatum.

The potential of penicillin as an antibiotic was established by Ernest Chain and Howard Florey. Penicillin was used extensively to treat American soldiers who were wounded in World War II. Fleming, Florey and Chain were awarded the Nobel Prize for this discovery.

The major steps in the commercial production of penicillin are summarised as follows:

a. Preparation of inoculum — A medium of corn liquor, lactose, salts and other ingredients are mixed, sterilised, cooled and pumped into a large container known as the fermenter.

b. The mould Penicillium chrysogenum is inoculated into the fermenter. Sterile air is forced through the fermenter during incubation.

c. After fermentation, the mould mycelium is removed by filtration and the penicillin produced is extracted in pure form after a series of processes which includes precipitation, re-dissolving and nitration.

Many antibiotics are produced in a similar manner. The major differences relate to the organism, composition of the medium and the method of extraction.

3. Citric Acid Production:

Citric acid is an important chemical used in medicines, food and candies, manufacture of ink, dyeing, etc. Aspergillus niger is the most commonly used mould for commercial production of citric acid. This mould is capable of converting sugar into citric acid. Many sugars may serve as the substrate for the production of citric acid. However, molasses is generally used.

4. Monoclonal Antibody and Other Bioactive Molecules:

Monoclonal antibodies are produced on a commercial scale. They are particularly significant in treating malignant cells, in immunosuppression during organ transplantation and for passive immunisation of specific infectious diseases. They also serve as analytical reagents for diagnosing cancer and infectious diseases and hormone assays.

Cyclosporin A is an immunosuppressive agent used in organ transplant patients. It is produced by a fungus, Trichoderma polysporum. The statins produced by the yeast Monascus purpureus is a blood cholesterol lowering agent. It acts as a competitive inhibitor for the enzyme which is responsible for the synthesis of cholesterol, thereby stopping its synthesis.

Application # 4. Microbes and Sewage Treatment:

Sewage is the liquid waste from houses and industry in villages, towns and cities. Sewage is mostly water, and contains substances such as faeces, urine, toilet papers, detergents, oils and other chemicals. It is dangerous if sewage is allowed to run into rivers or sea as it can be harmful to man and environment. The untreated sewage is known as raw sewage. Raw sewage contains bacteria, some of which may be pathogenic.

Also raw sewage may contain substances that provide nutrients for plants and microorganisms, which would eventually lead to extensive growth of algae in aquatic environments. This is known as eutrophication. Therefore, it is necessary to treat sewage to remove pathogenic organisms and nutrients.

Domestic sewage consists of 99.9% water, 0.02-0.03% suspended solids and soluble organic and inorganic substances. Organic compounds may be classified as nitrogenous or non-nitrogenous compounds. Nitrogenous compounds include urea, proteins, amines and amino acids and non-nitrogenous substances like carbohydrates, fats and soaps.

Biochemical oxygen demand or BOD is the amount of dissolved oxygen needed for the microbial oxidation of biodegradable organic matter in the sewage. This value is an indirect measure or organic matter in aquatic environments. Wastewater treatment uses microbes to decompose organic matter in sewage. The more the amount of organic material in the waste waters, higher the BOD. The ‘strength’ of wastewater is expressed in terms of BOD level.

Raw sewage contains millions of bacteria per milli-litre including the coliformes, Streptococci, spore forming bacilli and others originating in the intestinal tract of humans. Sewage is a potential source of pathogenic protozoa, bacteria and viruses. The causative organisms of cholera, dysentery and typhoid fever may occur in the sewage.

Waste water treatment is necessary before wastewater is disposed of without producing undesirable or even harmful effects.

Inadequately treated waste water leads to the following problems:

a. The microorganisms in the wastewater cause many types of diseases.

b. Pollution of water bodies makes them unsafe for human consumption.

c. Aquatic fauna gets affected and reduces drastically in number.

d. The recreational value of water bodies such as lakes and rivers decreases.

e. The oxygen supply in the water gets depleted by unstable organic matter in the sewage killing aquatic life.

f. Sewage causes offensive odour and is also an ugly sight to see.

Treatment of Sewage:

Wastewater treatment systems are many and varied. Two separate situations are discussed here – single dwelling structure and community/municipality systems.

1. Single Dwelling Units:

Treatment and disposal of wastewater and sewage in individual dwellings or structure such as hotels can be accomplished by anaerobic digestion or by aerobic metabolic processes. The most common system is the septic tank, which is an anaerobic digesting system. A septic tank is a sewage settling tank which is designed to retain the solids of the sewage entering the tank to permit its decomposition.

As sewage enters the tank, sedimentation occurs. The sediment solid is known as sludge, which is subjected to degradation by anaerobic bacteria. This step produces unstable end products that are high in BOD and odorous. The liquid is distributed under the soil surface.

This method is a satisfactory method for the disposal of sewage from small installations, where public systems are not available. But there is a danger of contamination of drinking water supply because the pathogenic microorganisms are not eliminated in this method.

2. Municipal Treatment Processes:

A series of treatment processes is involved in municipal wastewater treatment plants which are as follows:

a. Primary Treatment:

During this step, coarse solid materials are removed by a variety of mechanical techniques that include screening, grinding and grit chambers. After this the liquid that remains is treated to remove settle able solids. Sedimentation units help in concentrating and collecting the particulate material referred to as sludge. Following sedimentation, the sludge and the liquid effluents are processed separately.

b. Secondary Treatment of Liquid Effluent:

During this step, oxidation of organic material present in the liquid effluent is accomplished by microbes. The different methods are as follows, filtration by trickling filter; aeration by the activated sludge process and oxidation ponds.

The three methods have been discussed briefly:

i. Filtration by Trickling Filter:

The trickling filter consists of a bed of crushed stone, gravel or synthetic material with drains at the bottom of the tank. The liquid sewage is sprayed over the surface of the bed either by a rotating arm or through nozzles. The filtering medium is coated with a film of microbial flora that consists of bacteria, fungi, protozoa and algae. As the sewage seeps over the surface, the microorganisms metabolise the organic constituents into stable end products.

ii. Aeration by the Activated Sludge Process:

Vigorous aeration of the sewage results in the formation of floe. When the floe is permitted to settle and then added to fresh sewage which is vigorously aerated, flocculation occurs in a shorter time than before. Repetition of this process in the given sequence, i.e. addition of floe to fresh sewage, aeration, sedimentation, addition of sediment to fresh sewage and aeration, a stage is reached where complete flocculation occurs quickly within a few hours.

The particles of floe, i.e. activated sludge contains large number of metabolising bacteria, together with yeast, moulds and protozoa, which is very effective in the oxidation of organic compounds.

iii. Oxidation Ponds or Lagoons:

They are shallow ponds that are 2-4 feet deep designed to allow algal growth on waste water effluent.

c. Advanced Treatment:

This step is required only when the primary and secondary treatment are inefficient to treat wastewater. The treatment procedure includes physical, chemical and biological methods.

d. Final Treatment:

The liquid after the primary and secondary treatments is disinfected and discharged into a body of water. Disinfection is necessary to protect public health. The most common method of disinfection is chlorination, though other alternative methods exist. The use of ozone and ultraviolet light is becoming prevalent. Dissolved oxygen may be added to the treated waste water before final discharge.

e. Treatment and Disposal of Sludge:

The sludge that accumulates during sedimentation and solids recovered from the aerobic treatment processes are pumped into a separate tank for digestion under controlled conditions. The method of disposal is known as anaerobic sludge digestion. An anaerobic condition is maintained in the tank. The microorganisms act on the organic solids and degrade them to soluble substances and gaseous products.

Large amounts of gases consisting of methane (60-70%) and CO2 (20-30%) with smaller amounts of hydrogen and nitrogen are produced. The gas produced can be used as fuel for heating and other operations. Rapid digestion of sludge occurs at temperature equivalent to 60-70°C. This favours growth of thermophilic bacteria. A neutral pH of 7.0 is maintained. The treated sludge is disposed of in a landfill.

Composting is another method of disposal of sludge. The sludge is mixed with a bulking agent such as wood chips to enhance circulation of air. The mixture is allowed to undergo biological decomposition for about 21 days. The bulking agent is removed for final ‘curing’ of sludge. The sludge is transformed into a humus type material and is suitable for use as a fertiliser.

Sewage is being produced in large quantities because of increasing urbanisation. However, the numbers of sewage treatment plants are not sufficient to treat such large quantities. As a result sewage is often discharged into rivers leading to pollution and increase in water borne diseases.

In India, the Ministry of Environment and Forests has initiated the Ganga Action Plan and Yamuna Action Plan to save the rivers from pollution. Large number of sewage treatment plants are being built to ensure that only treated sewage are discharged into the rivers.

Application # 5. Microbes and Energy Generation:

Microbes have the potential of contributing to energy and fuel production in several ways. They serve as alternative energy source.

The microorganisms may serve as fuels in one of the following ways:

a. Waste products or plant or microbial biomass may be converted into liquid or gaseous fuels.

b. Microorganisms may be used to convert solar energy into biomass and in turn this biomass many be fermented to yield fuels.

c. It may also be possible to use the photo- synthetic membrane system of the microorganisms to convert solar energy into usable fuels.

Let us understand this application of microbes depending on the types of fuel produced.

1. Biogas Production:

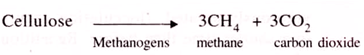

Biogas is 50-75% methane and the remainder is carbon dioxide with traces of nitrogen and other gases. Different groups of microorganisms are used in the process of fermentation. Methanogens are bacteria used for the production of methane from carbon dioxide and hydrogen. Methano bacterium is an example of a methanogen.

Methanogens are found in anaerobic sludge produced during sewage treatment. They are also present in the rumen of cattle. These bacteria help in the breakdown of cellulose found in the plant food eaten by the cattle. Animal dung known as ‘gobar’ is rich in these bacteria. Therefore dung is used for the generation of biogas. This gas is also known as gobar gas.

Other than animal manures and sewage sludge, food and domestic wastes, crop remains, paper wastes are also used as substrates for fermentation. Crops like maize, sugarcane, sugar-beet, water plants like water hyacinth may also be used.

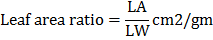

The overall equation can be represented as follows:

The biogas plant in India was built by the Indian Agriculture Research Institute (IARI) and the Khadi and Village Industries Commission (KVIC). The biogas plant is a tank which is 10-15 ft deep. The bio wastes and dung are added into the tank. The gas produced is collected and sent out through an outlet. The slurry left in the tank can be used as fertiliser. The biogas generated is used in cooking, lighting and fuel for car and tractor (Fig. 4).

2. Ethanol:

Ethanol or ethyl alcohol can be produced by the fermentation of carbohydrate containing material by microorganisms, especially yeasts.

Ethanol is a valuable alternative fuel resource. The mixture of gasoline and ethanol is called gasohol and can be used directly in internal combustion automobile engines. Ethanol and gasoline is mixed in specific proportions. E10 is the mixture of 10% ethanol and 90% gasoline, while E85 is 85% ethanol and 15% gasoline.