In this article we will discuss about the submerged vinegar fermentation process using frings acetator.

The first commercial equipment for the submerged process was described by Hromatka (1952). The basic patent emphasizes the need for uninterrupted aeration of the fermentation with fine bubbles as the necessary conditions for the production of satisfactory vinegar of high concentration. The process was further improved by the firm of Heinrich Frings, Bonn, for the production of vinegar with more than 12% acetic acid in a semi-continuous manner.

In this process each fermentation cycle takes the same time course, as preceding and following periods. The starting concentration of each cycle is about 7.5 g acetic acid per 100 ml and 5.5 vol.% ethanol. In order to obtain higher concentrations of acetic acid, the concentration at the beginning of the cycle may slowly be raised to 8 to 10 g/100 ml.

This can be achieved by discharging a smaller amount of vinegar than 40% at the end of the cycle and feeding mash of a higher “total concentration.” The concentration of ethanol at the start of the new fermentation cycle remains the same, i.e., about 5.5 vol.%. This process is already practiced commercially in factories producing up to 15 g per 100 ml acetic acid. The process requires excellent performance by the fermentor (called Acetator®).

The important parts of the equipment are:

1. The Frings Aerator:

It consists of a hollow body turbine surrounded by a stator as shown in. The hollow body (A) has 6 openings for the escape of air, which are arranged radially and which are open against the direction of rotation (B). The openings are preceded in the direction of rotation by vertical surfaces (C). These force liquid entering from above and below in intimate mixture with the sucked-in air through the stator (D) to the outside.

The rotor has an upper and a lower ring (E, F), The stator also consists of an upper and lower ring (G, H). The rings are connected with vertical baffles (I) which form an angle of 30° with the radius. These baffles receive the air-liquid emulsion very close to the rotor and direct it outward. The whole aerator works by “self-aspiration,” that is, without need for compressed air.

The rotor sits on the shaft of a motor mounted below the fermentor and turns at 1450 or 1750 rpm. The hollow body of the rotor is connected with an air suction pipe, Proper dimensions of the rotor and stator cause a sufficient amount of air to be aspirated, and cause the air-liquid emulsion to be thrown outward radially with a given speed. This speed is chosen in such a manner that the turbulence of the stream causes a uniform distribution of the air over the whole cross section of the fermentor.

Rotation of the entire fermentor contents is prevented by appropriate baffles. The particular behavior of Acetobacter cells during the fermentation makes an even distribution of aeration an absolute necessity. The maximum fermentation rate of an operating fermentor is limited by conditions prevailing at that point of the fermentor having the least aeration.

Because of the rapid mixing in the fermentor, each Acetobacter cell must eventually pass through that part of the fermentor which is inadequately aerated and suffers damage which cannot be compensated by increased aeration in other parts of the fermentor. This damage can increase to the point where the death rate reaches or surpasses the rate of multiplication of cells, causing a slowdown or even a complete cessation of the fermentation.

The extreme requirements for uniform aeration are rarely fulfilled by aeration devices commonly used in other fermentors. An instrument with which bubble size can be measured has been developed by Ebner (1973). This is suitable for determining a spectrum of air bubble sizes at many different points of the fermentor.

Optimal fermentation conditions can only be obtained if the size of bubbles (converted to equivalent pressures) and number of bubbles show the same average values at all measuring points lying at different heights and at different radial distances from the fermentor axis. The mean bubble diameter is about 1 mm with only small deviation from this value.

2. The Frings Defoamer:

Foam which forms occasionally must be prevented from leaving the fermentor. Its bulk must be removed at the end of the fermentation cycle in order to prevent its accumulation in the fermentor. The Frings aerator is equipped with a mechanical defoamer.

It consists of spiral housing (E) in which a rotor (B) turns at 1000 or 1450 rpm. The rotor is equipped with radial wings (F). At the gas exit side the rotor has a peripheral ring which runs tightly against a counter flange of the housing. Foam enters the housing with the exit gas at (A) and from there it enters the rotor axially.

Liquid and foam particles are thrown centrifugally to the outside and are pumped back into the fermentor through the return pipe (C). The air freed from foam flows axially from the inner part of the rotor into the exit duct (D). The defoamer adjusts automatically to varying requirements for foam removal and is activated by a foam electrode.

In order to remove the foam from the Acetator at the end of the fermentation cycle, the return pipe is connected to the discharge pipe through which the product is pumped out of the fermentor at the end of a cycle. This arrangement permits complete removal of foam so that there is no need for chemical defoamers. This is advantageous because vinegar is used as a food.

3. The Frings Alkograph:

An automatic instrument for measuring the percentage of alcohol for control of the fermentation has been introduced. It is called Alkograph. Small amounts of fermentor liquid flow continuously through the analyzer; first through a vessel which adjusts the temperature and then through 2 boiling vessels. The temperature of the boiling point of the incoming liquid is measured in the first boiling vessel.

While alcohol is distilled off continuously, the higher boiling point of the liquid from which ethanol has been removed is measured in the second boiling vessel. The difference in temperature is a measure of the ethanol content and is recorded automatically. It is independent of other components of the liquid and of variations in barometric pressure.

Other portions of the process can also be controlled automatically. The pump which pumps the vinegar out of the fermentor is actuated by a contact in the Alkograph and stopped when a certain level in the Acetator has been reached. A pump adding fresh mash is started at the same time. It is controlled in such a manner that the Acetator is filled slowly and with maintenance of a constant temperature.

When the desired liquid level in the Acetator has been reached, the pump is stopped. The device for automatic cooling stays in operation until the alkograph shows again the end of the fermentation cycle and activates the discharge pump. The length of a fermentation cycle is on the average about 36 hr.

Continuous fermentation can be carried out at low “total concentrations” in two ways. First, one may maintain a semi-continuous operation but reduce the discharged amounts drastically and create a sequence of short semi-continuous cycles, which approach the conditions of a continuous operation. Secondly, one can choose a truly continuous operation.

The Alkograph contact set at an ethanol concentration of 0.2 vol.% regulates by means of a controller a valve in the feed pipe. Continuous addition of mash is regulated so that the alcohol concentration is kept constant. Vinegar may be removed continuously through an overflow pipe or it may be pumped out at short intervals.

At this time the Frings Acetator is the technically most proficient equipment capable of handling all “total concentrations” from 5 to 15% automatically and all raw materials. Energy consumption is about 1260 kJ per liter of fermented alcohol.

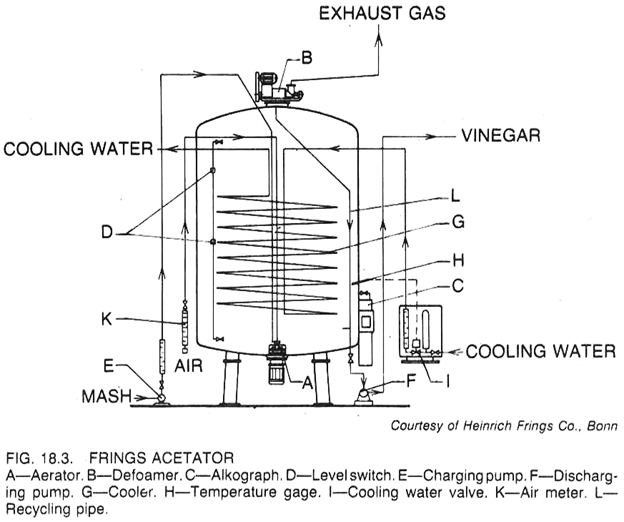

Figure 18.3 is a schematic drawing of the Acetator with the aerator (A), the defoamer (B), the Alkograph (C), level control switches (D), mash pump (E), vinegar pump (F), cooler (G), thermometer for temperature control (H), cooling water valve (I), airflow meter (K), and return pipe (L). Acetator vessels are made from stainless steel or wood and the instrumentation from stainless steel and polyvinylchloride.

Commercial sizes are for the fermentation of 75,150, 300, 600, and 1200 liters of pure ethanol in 24 hr. At the end of 1980, 428 Acetators were in operation in the world with a total capacity of 715 million liters of vinegar (at 10% acetic acid) per year. Of this capacity, 133 million liters are in the United States, 90 million in France, 44 million in Japan, and the rest is distributed over 50 other countries.

All other fermentation processes mentioned subsequently have less efficient aeration systems, and therefore they can operate only at “total concentrations” of up to 10%. They are either not automated or only partly automated and do not have mechanical defoamers. Therefore, the occasional use of chemical defoamers is required. Energy consumption is generally higher than with the Acetator.

4. The Yeomans Cavitator:

In the United States, the Cavitator of the firm Yeomans Brothers Co., Melrose Park, III., was sold between 1959 and 1970. The aerator consists of a simple hollow body turbine with arms and paddles. It is driven from above by a long, hollow shaft through which it sucks air. A cylinder which surrounds this shaft sucks liquid and foam from the top of the fermentor. The liquid air emulsion is ejected in an uncontrolled and uneven fashion.

A cooling coil with automatic temperature control completes the equipment. The Cavitator was used mainly for continuous cider vinegar fermentations with manual control and was not suitable for fermentations at higher concentrations. At the end of 1980 such Cavitators were still in operation in the United States and Japan with an annual capacity of about 50 million liters of vinegar.

The Bourgeois Process:

The process of the firm Bourgeois Freres & Cie. in Ballaigues, Switzerland, is based on the use of 2 fermentors with alternating fermentation cycles. In one of the fermentors the fermentation proceeds until the ethanol concentration has dropped to zero. A thermostat stops the aeration at this time. In the meantime fermentation proceeds in the other fermentor whose contents are used for the inoculation of the first fermentor.

A simple turbo mixer with air compressor and an automatic device for temperature control complete the equipment. The lack of ethanol in the finished product lessens its aroma. Therefore, the addition of ethanol after completion of the fermentation is recommended. Total production per fermentor volume is not favorable.

The system is not suitable for fermentations at higher “total concentrations” since, apart from lack of aeration, the cells of Acetobacter cannot be adapted to such higher concentrations. At the end of 1980 this type of equipment was mainly operated in Italy and Spain with a total capacity of about 20 million liters of vinegar per year.

The Fardon Process:

Several of the Fardon installations are operated for the production of malt vinegar. Aeration is provided by continuous pumping of the fermentor liquid through a Venturi tube which aspirates air, returning a liquid-air mixture to the fermentor. Cooling is done automatically.

Low productivity, high energy consumption, and restriction to mashes of low “total concentration” are the principal disadvantages of this system. At the end of 1980 several units were in operation, mainly in South Africa, with a total capacity of 10 million liters of vinegar per year.

Other Processes:

The following processes have not been expanded beyond a single installation and have not reached practical significance at the present time.

R.N. Greenshields (1972) uses a high, aerated fermentation tower. Malt mash is added continuously at the bottom, and malt vinegar (fully or not fully fermented) flows out at the top of the tower. Devices which largely prevent vertical mixing in the tower have been installed.

British Vinegars propose aeration at increased pressure as the fermentation progresses. Patentauswertung Vogelbusch GmbH (1964) suggests control of the fermentation through measurement of the ethanol concentration of the effluent gas.

Richardson (1959), Simonin and Bernard (1956), and Dothey (1952) provide aeration by pumping the liquid through air aspirating jets Fuchs (1963) uses a rotating self-priming impeller.