Industrial microbiology deals with the technological aspects of using microorganisms for large- scale production of valuable goods of human interest from comparatively inexpensive raw materials. For obtaining a useful product, a single strain of microorganism has to be grown in a mass-culture free from other contaminating organisms.

This presents an important challenge which has to be managed by the technologists. Also, the mass-culture should be sufficiently large to make the production cost-effective. The organism chosen for industrial application must also produce the desirable substance in sufficiently large amount under the industrial conditions to make large-scale manufacture economically viable.

The microbial world is vast and highly diverse. They possess metabolic abilities to produce a great many varieties of substances. The prospects of utilizing such substances for human benefit are practically unlimited.

A chronological review of large-scale exploitation of microorganisms for obtaining products of human interest reveals that till the end of the 19th century, the major products were ethanol in the form of alcoholic beverages, baker’s yeast for leavening of bread, and vinegar. Pure culture of yeast was first used in 1886 in Carlsberg brewery for manufacture of beer.

An important milestone in-the history of industrial microbiology was production of glycerol as a byproduct of alcoholic fermentation. The shortfall in supply of glycerol — which was necessary for manufacture of explosives during the First World War (1914-1918) — initiated Neuberg in Germany to develop a method of large-scale production of glycerol. The method consisted of arresting the normal glycolytic pathway of yeast using sodium bisulfite. Glycerol was obtained as a by-product with a reduced yield of alcohol.

Another important development, necessitated by serious shortage of acetone in Great Britain during the First World War was discovery of acetone-butanol fermentation by Weizmann who later became the first President of Israel.

Acetone was necessary also for making explosives which were used against Germany, a country which supplied most of acetone to Great Britain before war. Weizmann found that an anaerobic bacterium, Clostridium acetobutylicum could produce acetone and butanol.

Among the early commercial products obtained from more or less large-scale cultures of microorganisms were some organic acids, specially citric acid, gluconic acid and lactic acid. Citric acid finds many uses in making soft drinks, lozenges, ink and pharmaceutical preparations.

Gluconic acid is mainly used as its calcium salt in pharmaceuticals. Both these acids are produced by Aspergillus niger. For lactic acid production, generally homo-fermentative lactic acid bacteria are used, although several fungi of the genus Rhizopus can also produce lactic acid along with other organic acids.

A major break-through in industrial microbiology was the development of the technology for large- scale production of penicillin during the Second World War (1939-1945). Soon after the end of the war, the technology of penicillin manufacture spread rapidly too many countries.

It ushered in a new era of microbial industry and paved the pathway for development of not only many other antibiotics, but also of other microbial products, like amino acids, vitamins, enzymes, biopolymers etc., all of which required large-sized fermentation vessels, aseptic conditions, submerged mass-culture and techniques for recovery of the fermentation product.

An important outcome of antibiotic research was development of laboratory techniques for screening of desirable organisms producing valuable substances. Search antibiotic producing organisms required testing of thousands of all kinds of organisms from which only a few possessed the capability of producing an antibiotic. Various ingenious techniques were perfected to minimize time and labour for such extensive screening programmes. These proved valuable for searching out microorganisms producing other products of human interest.

Another important landmark in microbe-based industry was the amino acid fermentation which was made possible by the discovery of Kinoshita (1957) that a bacterium, Corynebacterium glutamicum produced substantial amount of L-glutamic acid in the growth medium. This discovery initiated a new branch of industrial microbiology. Soon, by induction of mutation in other bacteria, many amino acid- producing organisms were developed.

Production of single-cell proteins from bacteria and yeasts was initiated in 1980s with great enthusiasm, although it did not last long. The boom in SCP fermentation subsided by the end of 1980s due to several reasons including ready availability of cheaper sources of protein, like soybean and fish-meal.

Among other products of microbial fermentation are some polysaccharide gums, biodegradable surface-active agents, enzymes, vitamins and bio-insecticides. Xanthan gum, obtained from Xanthomonas campestris, has a wide range of application in food processing, manufacture of paints, textile printing, insecticide sprays, deodorants, explosive manufacture and oil-drilling.

Alginic acid, normally extracted from algae can now be produced using Azotobacter vinelandii. This agent has also multiple practical uses including as a sizing agent and in pharmaceutical preparations. Increasing environment consciousness has urged a search for biodegradable surfactants or detergents. Several glycolipids of bacterial origin having hydrophilic and hydrophobic moieties in the molecules have shown promise as surfactants.

Rhamnolipid R3 produced by Pseudomonas aeruginosa, trehalose tetradiester obtained from Rhodococcus erythropolis and surfactin from Bacillus subtilis are some compounds showing promise as surface-active agents. Bio-insecticides have aroused interest for similar concern about environmental pollution caused by customary biocides. Bacillus thuringiensis has long been known to possess insecticidal property.

Other species of the genus have also been discovered possessing similar property. In more recent years, the gene coding for the insecticidal protein has been successfully cloned into E. coli and in crop plants, like tomato. This and similar other gene transfers have been made possible by the development of recombinant DNA technology since 1970s.

This powerful technology has provided a very efficient tool of introducing genes into bacteria and yeast enabling them to produce proteins of taxonomically unrelated organisms. It has been possible, for example, to produce human proteins in bacteria and yeasts.

The recombinant DNA technology has naturally made a great impact on many branches of biology, including industrial microbiology. In traditional microbial fermentation, the process is dependent on the capability to produce a specific product of human interest by a microbial strain determined by its own genetic make-up.

Recombinant DNA technology brought in a qualitative change in the capability of an organism by enabling it to produce a product which could never have happened, had not been the gene coding for the product been transferred from another organism.

As a consequence, a new branch has come to be known as modern microbial technology. However, it should be clear that this new technology is used only for creating genetically engineered organisms producing novel products which are then cultivated following the traditional industrial microbiological processes to secure the product.

To avoid confusion, it should be mentioned that the term fermentation is used in microbiological industries to mean any large-scale process in which microorganisms are used to obtain a specific product. Thus, one speaks of acetic acid (vinegar) fermentation which in the later phase is an aerobic process or an amino acid fermentation which is a fully aerobic one.

On the other hand, acetone-butanol fermentation is truly anaerobic. The term fermentation is thus not used in strict biochemical sense which defines it as a metabolic process resulting in release of energy from an oxidisable organic substrate without participation of oxygen or electron transport system, and transfer of hydrogen and electrons to some organic molecule(s) which are thereby reduced.

The objective of all industrial fermentations, whether traditional or modern, is to harvest a specific product which is generally a metabolite of the organism employed, or sometimes as in case of SCP, the biomass itself. More often, the cultivated organism secretes the product in the culture medium.

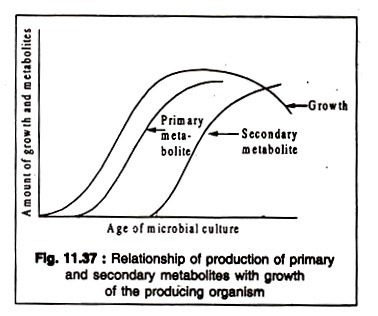

The product may be a primary metabolite or a secondary metabolite. A primary metabolite is-one which is required for the growth of the organism and it is produced in the actively growing phase or trophophase. Examples of primary metabolites are amino acids, lactic acid, ethanol, etc.

Although lactic acid and ethanol are not utilized by the producing organisms, they have to be produced to regenerate NAD from NADH2, because NAD is required for oxidation of phospho-glycerin- aldehyde to phosphoglyceric acid, so that glycolysis can continue.

A secondary metabolite, such as penicillin and other antibiotics, is produced after active growth ceases that is in the idiophase. The secondary metabolites are not essential for the organisms producing them.

The relationship of production of primary and secondary metabolites and growth of producing organisms is graphically shown in Fig. 11.37: