Some details on the production of important organic acids by fermentation are given below:

Contents

1. Citric Acid:

Citric acid was first discovered as a constituent of lemon. Today, we know citric acid as an intermediate of ubiquitous Krebs cycle (citric acid cycle), and therefore, it is present in every living organism. In the early days, citric acid was isolated from lemons (that contain 7-9% citric acid), and today about 99% of the world’s citric acid comes from microbial fermentation.

Applications of Citric Acid:

1. Citric acid, due to its pleasant taste and palatability, is used as a flavoring agent in foods and beverages e.g., jams, jellies, candies, desserts, frozen fruits, soft drinks, wine. Besides brightening the colour, citric acid acts as an antioxidant and preserves the flavors of foods.

2. It is used in the chemical industry as an antifoam agent, and for the treatment of textiles. In metal industry, pure metals are complexed with citrate and produced as metal citrates.

3. In pharmaceutical industry, as trisodium citrate, it is used as a blood preservative. Citric acid is also used for preservation of ointments and cosmetic preparations. As iron citrate, it serve as a good source of iron.

4. Citric acid can be utilized as an agent for stabilization of fats, oils or ascorbic acid. It forms a complex with metal ions (iron, copper) and prevents metal catalysed reactions. Citric acid is also used as a stabilizer of emulsions in the preparation of cheese.

5. In detergent/cleaning industry, citric acid has slowly replaced polyphosphates.

Microbial Strains for Citric Acid Production:

Many microorganisms can produce citric acid. The fungus Aspergillus Niger is most commonly used for industrial production of citric acid. The other organisms (although less important) include A. clavatus, A. wentii, Penicillium luteum, Candida catenula, C. guilliermondii and Corynebacterium sp.

For improved industrial production of citric acid, mutant strains of A. Niger have been developed. The strains that can tolerate high sugar concentration and low pH with reduced synthesis of undesirable byproducts (oxalic acid, isocitric acid and gluconic acid) are industrially important.

Microbial Biosynthesis of Citric Acid:

Citric acid is a primary metabolic product (of primary metabolism) formed in the tricarboxylic acid (Krebs) cycle. Glucose is the predominant carbon source for citric acid production. The biosynthetic pathway for citric acid production involves glycolysis wherein glucose is converted to two molecules of pyruvate. Pyruvate in turn forms acetyl CoA and oxaloacetate which condense to finally give citrate. The major steps in the biosynthesis of citric acid are depicted in Fig. 24.1.

Enzymatic regulation of citric acid production:

During the synthesis of citric acid, there is a tenfold increase in the activity of the enzyme citrate synthase while the activities of other enzymes (aconitase, isocitrate dehydrogenase) that degrade citric acid are reduced. However, recent evidence does not support the theory that reduction in the operation of tricarboxylic acid (i.e. degradation of citric acid) contributes to accumulation of citric acid.

Increased citric acid is more likely due to enhanced biosynthesis rather than inhibited degradation. Further, there are anaplerotic reactions that replenish the TCA cycle intermediates to keep the cycle continuously in operation. Pyruvate carboxylase that converts pyruvate to oxaloacetate is also a key enzyme in citric acid production.

Yield of citric acid:

Theoretically, the yield of citric acid for the most commonly used substrate sucrose has been calculated. It is worked out that from 100 g sucrose, 112 g of anhydrous citric acid or 123 g of citric acid — 1 hydrate can be formed. However, due to oxidation of sugar to CO2 during trophophase, the yield of citric acid is lower than the calculated.

Factors in the Regulation of Citric Acid Production:

Strict maintenance of controlled nutrient conditions is very crucial for maximal production of citric acid. The optimal conditions that have been worked out for A. Niger for the production of citric acid are briefly described (Table 24.1).

Carbohydrate source:

A wide range of raw materials can be used for the supply of carbohydrates. These include molasses (sugar cane or sugar beet), starch (from potatoes), date syrup, cotton wastes, banana extract, sweet potato pulp, and brewery waste and pineapple waste water.

A high yield of citric acid production occurs if the sugars that are rapidly metabolised are used e.g. sucrose, glucose, maltose. At present, cane molasses and beet molasses are commonly used. The variations in the composition of molasses (seasonal and production level), have to be carefully considered for optimising citric acid production.

The concentration of carbohydrate significantly influences citric acid production. Ideally, the sugar concentration should be 12-25%. At a concentration less than 5% sucrose, citric acid formation is negligible, and increases as the concentration is raised to 10% and then stabilizes (Fig. 24.2). It is believed that a high sugar concentration induces increased glucose uptake and consequently enhanced citric acid production.

Trace metals:

Certain trace elements (Fe, Cu, Zn, Mn, Mg, Co) are essential for the growth of A. Niger. Some of the trace metals particularly Mn2+, Fe3+ and Zn2+ increase the yield of citric acid. The effect of manganese ions has been investigated to some extent. These ions promote glycolysis and reduce respiration; both these processes promote citric acid production.

As regards iron, it is a cofactor for the enzyme aconitase (of TCA cycle). It is estimated that an Fe concentration of 0.05-0.5 ppm is ideal for optimal citric acid production. At higher Fe concentration, the yield is lower which can be reversed to some extent by adding copper.

pH:

The pH of the medium influences the yield of citric acid, and it is maximal when pH is below 2.5. At this pH, the production of oxalic acid and gluconic acid is suppressed. Further, at low pH, transport of citric acid is much higher. If the pH is above 4, gluconic acid accumulates at the expense of citric acid. And when the pH goes beyond 6, oxalic acid accumulates. Another advantage with low pH is that the risk of contamination is very minimal, since many organisms cannot grow at this pH.

Dissolved O2:

The yield of citric acid production substantially increases when the dissolved O2 tension is higher. This can be achieved by strong aeration or by sparging with pure O2. It has been observed that sudden interruptions in O2 supply (as occurs during power breakdowns) cause drastic reduction in citric acid production without harming the growth of the organism.

Nitrogen source:

Ammonium salts, nitrates and urea are the nitrogen sources used in the media for citric acid production. All the three compounds are equally good sources, as long as they do not adversely affect the pH of the medium. If molasses are used for nutrient supply, addition of extra nitrogen source is not required. However, some workers have shown that exogenous addition of ammonium ions stimulates citric acid production.

Production Processes for Citric Acid:

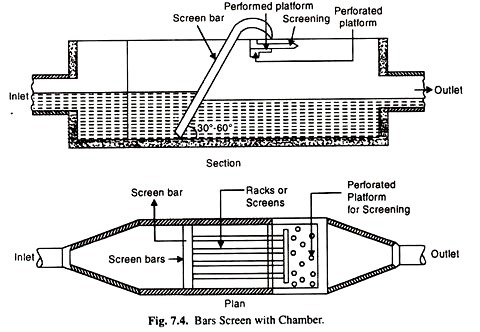

There are two processes by which citric acid can be industrially produced — the surface process and submerged process (Fig. 24.3).

The surface process:

This is characterized by growing the microorganisms as a layer or a film on a surface in contact with the nutrient medium, which may be solid or liquid in nature. Thus, the surface process has supported-growth systems.

The submerged process:

In this case, the organisms are immersed in or dispersed throughout the nutrient medium. There are two types of submerged fermenters (bioreactors) stirred bioreactors and airlift bioreactors.

Surface Processes:

Solid surface fermentation:

Surface processes using solid substrates are particularly carried out in less developed areas of some Asian countries. The solid substrates such as wheat bran or pulp from sweet potato starch are used, as culture media. The pH of the medium is adjusted to 4-5, and then sterilized. Now the inoculum in the form of spores of A. niger is spread as layers (3-6 cm thickness) and incubated at 28°C.

The growth of the organisms can be accelerated by the addition of α-amylase. Solid-state fermentation takes about 80 to 100 hours for maximal production of citric acid. At the end of the process, citric acid can be extracted into hot water and isolated.

Liquid surface fermentation:

Surface fermentation using liquid as nutrient medium is the oldest method for citric acid production. It is still in use due to a simple technology, low energy costs and higher reproducibility. Further, the interference of trace metals and dissolved O2 tension are minimal. The labour costs are however, higher since the manpower requirements are more for cleaning the systems. About 20% of the citric acid in the world is produced by surface processes.

The nutrient supply for surface fermentation normally comes from beet molasses. The fermentation is usually carried out in aluminium trays filled with sterile nutrient medium. The inoculum in the form of spores is sprayed over the medium. A sterile air is passed for supplying O2 as well as cooling. The temperature is maintained around 30°C during fermentation.

As the spores germinate (that occurs within 24 hours of inoculation), a layer of mycelium is formed over the medium. The pH of the nutrient medium falls to less than 2, as the mycelium grows in size and forms a thick layer on the surface of the nutrient solution. The fermentation is stopped after 7-15 days.

The mycelium and nutrient solution are separated. The mycelium is mechanically pressed and thoroughly washed to obtain maximum amount of citric acid. The nutrient solution is subjected to processing for the recovery of citric acid. The final yield of citric acid is in the range of 0.7-0.9 of per gram of sugar.

Submerged Processes:

Around 80% of the world’s supply of citric acid is produced by submerged processes. This is the most preferred method due to its high efficiency and easy automation. The disadvantages of submerged fermentation are — adverse influence of trace metals and other impurities, variations in O2 tension, and advanced control technology that requires highly trained personnel.

Two types of bioreactors are in use— stirred tanks and aerated towers. The vessels of the bioreactors are made up of high-quality stainless steel. The sparging of air occurs from the base of the fermenter.

The success and yield of citric acid production mainly depend on the structure of mycelium. The mycelium with forked and bulbous hyphae and branches which aggregate into pellets is ideal for citric acid formation. On the other hand, no citric acid production occurs if the mycelium is loose and filamentous with limited branches. An adequate supply of O2 (20-25% of saturation value) is required for good production of citric acid. The ideal aeration rate is in the range of 0.2-1 vvm (volume/ volume/ minute).

The submerged fermenters have the problem of foam formation which may occupy about 1 /3rd of the bioreactor. Antifoam agents (e.g. lard oil) and mechanical antifoam devices are used to prevent foaming. Nutrient concentration is very important in the industrial production of citric acid. A diagrammatic representation of sucrose, citric acid and biomass concentration with respect to cultivation time is shown in Fig. 24.4. It is estimated that under optimal conditions, in about 250-280 hours, 100- 110 g/l of citric acid is obtained from 140 g/l of sucrose with a biomass (dry weight) of 8-12 g/l.

Production of Citric Acid from Alkanes:

Both yeasts and bacteria can be used for citric acid production from n-alkanes (C9-C23 hydrocarbons). The citric acid yield is better from hydrocarbons compared to sugars i.e. 145% of citric acid from paraffin. The most commonly used organism is Candida lipolytica. The fermentation can be carried out in batch, semi-continuous or continuous modes. The pH should be kept above 5. The major limitations of citric acid production from alkanes are—very low solubility of alkanes and increased production of unwanted isocitric acid.

Recovery of Citric Acid:

The steps for the recovery of citric acid either from surface process or submerged process are comparable (Fig. 24.5). The recovery starts with the filtration of the culture broth and washing of mycelium (which may contain about 10% of citric acid produced). Oxalic acid is an unwanted byproduct and it can be removed by precipitation by adding lime at pH < 3.

The culture broth is then subjected to pH 7.2 and temperature 70-90°C for precipitating citric acid. For further purification, citric acid is dissolved in sulfuric acid (calcium sulfate precipitate separates). The final steps for citric acid recovery are — treatment with activated charcoal, cation and anion-exchangers and crystallization.

Citric acid monohydrate formed below 36°C is the main commercial product. Above 40°C, citric acid crystallizes in an anhydrous form. The degree of purity of citric acid produced depends on the purpose for which it is required. For instance, pure forms of citric acid are needed for use in food preparations, while for industrial use it can be crude form.

2. Gluconic Acid:

Gluconic acid can be produced by several bacteria and fungi. Glucose, on a simple direct dehydrogenation, forms D-gluconolactone which is then converted to gluconic acid.

Applications of Gluconic Acid:

1. Gluconic acid is used in the manufacture of metals, stainless steel and leather, as it can remove the calcareous and rust deposits.

2. It is used as an additive to foods and beverages.

3. Gluconic acid has pharmaceutical applications — calcium and iron therapy.

4. Sodium gluconate is used as a sequestering agent in many detergents.

5. Gluconate is used for desizing polyester or polyamide fabrics.

6. It is utilized in the manufacture of highly resistant (to frost and cracking) concrete.

Microbial Production of Gluconic Acid:

Gluconic acid can be produced by a wide variety of prokaryotic and eukaryotic microorganisms.

Bacterial species of the genera— Gluconobacter, Acetobacter, Pseudomonas, Vibrio.

Fungal species of the genera—Aspergillus, Penicillium, Gliocladium.

Principle of production:

The enzymatic reactions for the formation of gluconic acid in Gluconobacter suboxidans (bacteria) and Aspergillus niger (fungus) are depicted in Fig. 24.6.

In bacteria, intracellular glucose is converted to extracellular gluconic acid. A membrane bound enzyme, glucose dehydrogenase utilizes pyrroloquinoline Quinone (PQQ) as coenzyme and converts glucose to 5-D-gluconolactone which undergoes hydrolysis (spontaneous or enzymatic) to form gluconic acid.

As regards fungal production, glucose is oxidized by the extracellular enzyme glucose oxidase to form 8-D-gluconolactone, which subsequently gets converted to gluconic acid by lactonase. Glucose oxidase is an inducible enzyme that can be induced by high concentrations of glucose, and at pH above 4. It is believed that H2O2 produced by glucose oxidase acts as an antagonist against other microorganisms (antimicrobial activity) in the surroundings.

Production Process for Gluconic Acid:

Submerged processes, by employing either A. niger or G. suboxidans, are used for producing gluconic acid. The culture medium contains glucose at a concentration of 12-15% (usually obtained from corn). The fermentation is carried out at pH 4.5-6.5 and at temperature 28-30°C for a period of about 24 hours.

Increasing the supply of O2 enhances gluconic acid yield. Biotechnologists exploit the fermentation process of gluconic acid for the production of the enzyme glucose oxidase, besides producing calcium gluconate and sodium gluconate.

Chemical synthesis of gluconic acid:

By employing the immobilized enzyme glucose oxidase, gluconic acid can also be produced.

3. Lactic Acid:

Lactic acid occurs in two isomeric forms i.e. L (+) and D (-) isomers, and as a racemic mixture (DL-lactic acid). The isolation of lactic acid from milk was done in 1798. It was the first organic acid produced by microorganisms in 1880. Today, lactic acid is competitively produced both by microbiological and chemical methods.

Applications of Lactic Acid:

There are different grades of lactic acid mainly based on the percentage of lactic acid. The grades and their applications are given in Table 24.2.

Microorganisms for Production of Lactic Acid:

Lactic acid producing bacteria are broadly categorized into two types.

Hetero-fermentative bacteria—produce other byproducts, besides lactic acid, and therefore are not useful for industrial production of lactic acid. These bacteria are employed in food or feed preservation.

Homo-fermentative bacteria—specialised for exclusive production of lactic acid and therefore are suitable for industrial purpose.

Lactobacillus sp are used for lactic acid production. However, there are variations in the substrates utilised as indicated below.

Biosynthesis of lactic acid:

The synthesis of lactic acid occurs through glucose oxidation by glycolysis to produce pyruvate which on reduction gives lactic acid. The reducing equivalents (NADH++H+) produced during the oxidation of glyceraldelyde 3-phosphate are utilised by .the enzyme lactate dehydrogenase to form lactate (Fig. 24.7). Most of the lactic acid producing microorganisms normally produce only one isomer of lactic acid L(+) or D(-). However, some bacteria which usually occur as infection can form racemic mixture.

Production Process for Lactic Acid:

The fermentation medium contains 12-15% of glucose, nitrogen and phosphate containing salts and micronutrients. The process is carried out at pH 5.5-6.5 and temperature 45-50°C for about 75 hours. Generally, the strains operating at higher temperature (45-60°C) are preferred, since it reduces the need for medium sterilization.

As the lactic acid is produced, it has to be removed since it is toxic to the organisms. This can achieved either by a continuous culture technique or by removal of lactic acid by electro dialysis. Theoretically, every molecule of glucose forms two molecules of lactic acid. About 90% of theoretical yield is possible in fermentation industry. L(+) Lactic acid is predominantly produced. The outline of the steps involved in the recovery lactic acid is depicted in Fig. 24.8.

4. Acetic Acid:

The production of acetic acid, in the form of vinegar (used as a refreshing drink), from alcoholic liquids has been known for centuries.

Microorganisms Used for Production of Acetic Acid:

The commercial production of acetic acid is carried out by a special group of acetic acid bacteria, which are divided into two genera.

Gluconobacter that oxidizes ethanol exclusively to acetic acid.

Acetobacter that oxidizes ethanol first to acetic acid, and then to CO2 and H2O. These over- oxidizers are Gram-negative and acid tolerant e.g. A. aceti, A. peroxidans, A. pasteurianus.

Biosynthesis of acetic acid:

Acetic acid is a product of incomplete oxidation of ethanol. Ethanol is first oxidized by alcohol dehydrogenase to acetaldehyde which then gets hydrated to form acetaldehyde hydrate. The latter is then acted upon by acetaldehyde dehydrogenase to form acetic acid (Fig. 24.9).

Production Process for Acetic Acid:

For every molecule of ethanol oxidised, one molecule of acetic acid is produced. Thus, high- yielding strains can produce 11-12% acetic acid from 12% alcohol. For optimal production, adequate supply of oxygen is very essential. Insufficient O2, coupled with high concentration of alcohol and acetic acid result in the death of microorganisms. Surface fermentation or submerged fermentation processes can be carried out to produce acetic acid. Trickling generation process, a type of surface fermentation, is very commonly used.

Recovery:

The acetic acid produced is clarified by filtration and then subjected to decolourization by K4(FeCN)6.

Production of Vinegar:

Vinegar is an aqueous solution containing about 4% by volume acetic acid and small quantities of alcohol, salts, sugars and esters. It is widely used as a flavoring agent for processed liquid foods such as sauces and ketchups. The starting materials for vinegar production are wine, whey, malt (with low alcohol content). Vinegar production can be carried out either by surface process (trickling generator) or by submerged process.

Surface process:

The fermentation material is sprayed over the surface which trickles through the shavings that contain the acetic acid producing bacteria. The temperature is around 30°C on the upper part while it is around 35°C on the lower part. Vinegar is produced in about 3 days.

Submerged process:

The fermentation bioreactors are made up of stainless steel. Aeration is done by a suction pump from the top. The production rate in the submerged process is about 10 times higher than the surface process.

5. L-Ascorbic Acid:

L-Ascorbic acid is the commonly used chemical name for the water soluble vitamin C. This vitamin forms a redox system and participates in several biological processes. It is intimately involved in the biosynthesis of collagen, the most abundant protein in the human body. Vitamin C also protects the body against carcinogenic nitrosamines and free radicals. The deficiency of ascorbic acid causes scurvy.

Applications of Ascorbic Acid:

Because of the wide range of physiological and beneficial functions of ascorbic acid, its commercial production assumes significance. Vitamin C is mainly used in food and pharmaceutical industries.

Industrial Production of Ascorbic Acid:

Ascorbic acid is commercially produced by a combination of several chemical steps, and one reaction of biotransformation brought out by microorganisms. This process is referred to as Reichstein-Grussner synthesis (Fig. 24.10B). D-Glucose is first converted to D-sorbitol. Oxidation of D-sorbitol to L-sorbose is carried out by Acetobacter xylinum or A. suboxydans (The enzyme being sorbitol dehydrogenase).

A submerged bioreactor fermentation process is ideal for this reaction. It takes about 24 hours at temperature 30-35°C. Sorbose by a couple of chemical reactions can be finally converted to L-ascorbic acid. Normally, about 100 g of ascorbic acid is produced from 200 g of glucose in Reichstein-Grussner synthesis.

Two-step fermentation process:

In this, D-glucose is converted to 2, 5-diketogluconic acid by Erwinia, Acetobacter or Gluconobacter sp. In the second step, Corynebacterium sp converts 2, 5-diketogluconic acid to 2-keto-L-gluconic acid, (Fig. 24.10A). It is also possible to involve Bacillus megaterium for converting L-sorbose to 2-keto-L- gluconic acids. The latter, by chemical reactions, can be converted to ascorbic acid.

Production via L-gulonolactone:

Ascorbic acid can also be synthesized via- gulonolactone which can be directly converted to L-ascorbic acid by the enzyme L-gulonolactone dehydrogenase (Fig. 24.10C).

Direct Production of Ascorbic Acid by Fermentation:

Several workers are trying to produce ascorbic acid directly from glucose. Microalgae of Chlorella have shown some promising results, although the yield is very low.

Genetic Engineering for Ascorbic Acid Production:

Biotechnologists have been successful in cloning and expressing the gene for 2, 5-diketogluconic acid reductase of Corynebacterium sp into Erwinia herbicola. By doing this, the two step fermentation process (Fig. 24.10A) has been reduced to one. The genetically engineered Erwinia cells were able to convert D-glucose directly to 2-keto-L-gluconic acid.

This is certainly advantageous since the metabolic capabilities of two different microorganisms could be combined into one organism. However, the yield of ascorbic acid by the hybrid strain was very low. Scientists are now trying to alter certain amino acids in 2-5 diketogluconic acid reductase and increase the catalytic activity of this enzyme.

6. Itaconic Acid:

Itaconic acid is used in plastic industry, paper industry and in the manufacture of adhesives. Itaconic acid can be commercially produced by Aspergillus itoconicus and A. terreus. The biosynthesis of itaconic acid occurs by way of Krebs cycle. The metabolite cis-aconitic acid (formed from citric acid) undergoes decarboxylation catalysed by the enzyme cis-aconitic decarboxylase (Fig. 24.11).

Itaconic acid is oxidised to itatartaric acid by itaconic acid oxidase. This enzyme has to be inhibited for a maximum yield of itaconic acid. This can be achieved by adding calcium. Batch submerged fermentation process is commonly used for itaconic acid production. The yield is around 75% of the theoretical calculation when the medium contains 15% sucrose.