Read this article to learn about the application and commercial production of enzymes in the field of enzyme technology.

Enzymes are the biocatalysts synthesized by living cells. They are complex protein molecules that bring about chemical reactions concerned with life. It is fortunate that enzymes continue to function (bring out catalysis) when they are separated from the cells i.e. in vitro. Basically, enzymes are nontoxic and biodegradable. They can be produced in large amounts by microorganisms for industrial applications.

Enzyme technology broadly involves production, isolation, purification and use of enzymes (in soluble or immobilized form) for the ultimate benefit of humankind. In addition, recombinant DNA technology and protein engineering involved in the production of more efficient and useful enzymes are also a part of enzyme technology.

The commercial production and use of enzymes is a major part of biotechnology industry. The specialties like microbiology; chemistry and process engineering, besides biochemistry have largely contributed for the growth of enzyme technology.

Applications of Enzymes:

Enzymes have wide range of applications. These include their use in food production, food processing and preservation, washing powders, textile manufacture, leather industry, paper industry, medical applications, and improvement of environment and in scientific research.

As per recent estimates, a great majority of industrially produced enzymes are useful in processes related to foods (45%), detergents (35%), textiles (10%) and leather (3%). For details on the applications of individual enzymes, Tables 21.1-21.3 must be referred.

Commercial Production of Enzymes:

Microbial enzymes have been utilized for many centuries without knowing them fully. The first enzyme produced industrially was taka-diastase (a fungal amylase) in 1896, in United States. It was used as a pharmaceutical agent to cure digestive disorders.

In Europe, there existed a centuries old practice of softening the hides by using feces of dogs and pigeons before tanning. A German scientist (Otto Rohm) demonstrated in 1905 that extracts from animal organs (pancreases from pig and cow) could be used as the source of enzymes-proteases, for leather softening.

The utilization of enzymes (chiefly proteases) for laundry purposes started in 1915. However, it was not continued due to allergic reactions of impurities in enzymes. Now special techniques are available for manufacture, and use of enzymes in washing powders (without allergic reactions). Commercial enzymes can be produced from a wide range of biological sources. At present, a great majority (80%) of them are from microbial sources.

The different organisms and their relative contribution for the production of commercial enzymes are given below:

Fungi – 60%

Bacteria – 24%

Yeast – 4%

Streptomyces – 2%

Higher animals – 6%

Higher plants – 4%

A real breakthrough for large scale industrial production of enzymes from microorganisms occurred after 1950s.

Enzymes from animal and plant sources:

In the early days, animal and plant sources largely contributed to enzymes. Even now, for certain enzymes they are the major sources.

A selected list of plant (Table 21.1) and animal (Table 21.2) enzymes with their sources and applications are given:

Animal organs and tissues are very good sources for enzymes such as lipases, esterases and proteases. The enzyme lysozyme is mostly obtained from hen eggs. Some plants are excellent sources for certain enzymes-papain (papaya), bromelain (pineapple).

Limitations:

There are several drawbacks associated with the manufacture of enzymes from animal and plant sources. The quantities are limited and there is a wide variation in their distribution. The most important limitations are the difficulties in isolating, purifying the enzymes, and the cost factor. As regards extraction of industrial enzymes from bovine sources, there is a heavy risk of contamination with bovine spongiform encephalopathy (BSE is prion disease caused by ingestion of abnormal proteins). For these reasons, microbial production of enzymes is preferred.

Enzymes from mammalian cell cultures:

There exists a possibility of producing commercial enzymes directly by mammalian cell cultures. But the main constraint will the cost factor which will be extremely high. However, certain therapeutic enzymes such as tissue plasminogen activator are produced by cell cultures.

Enzymes from microbial sources:

Microorganisms are the most significant and convenient sources of commercial enzymes. They can be made to produce abundant quantities of enzymes under suitable growth conditions. Microorganisms can be cultivated by using inexpensive media and production can take place in a short period.

In addition, it is easy to manipulate microorganisms in genetic engineering techniques to increase the production of desired enzymes. Recovery, isolation and purification processes are easy with microbial enzymes than that with animal or plant sources.

In fact, most enzymes of industrial applications have been successfully produced by microorganisms. Various fungi, bacteria and yeasts are employed for this purpose. A selected list of enzymes, microbial sources and the applications are given in Table 21.3.

Aspergillus niger— A unique organism for production of bulk enzymes:

Among the microorganisms, A. niger (a fungus) occupies a special position for the manufacture of a large number of enzymes in good quantities. There are well over 40 commercial enzymes that are conveniently produced by A. niger. These include a-amylase, cellulase, protease, lipase, pectinase, phytase, catalase and insulinase.

The Technology of Enzyme Production—General Considerations:

In general, the techniques employed for microbial production of enzymes are comparable to the methods used for manufacture of other industrial products .The salient features are briefly described.

1. Selection of organisms

2. Formulation of medium

3. Production process

4. Recovery and purification of enzymes.

An outline of the flow chart for enzyme production by microorganisms is depicted in Fig. 21.1.

Selection of organism:

The most important criteria for selecting the microorganism are that the organism should produce the maximum quantities of desired enzyme in a short time while the amounts of other metabolite produced are minimal. Once the organism is selected, strain improvement for optimising the enzyme production can be done by appropriate methods (mutagens, UV rays). From the organism chosen, inoculum can be prepared in a liquid medium.

Formulation of medium:

The culture medium chosen should contain all the nutrients to support adequate growth of microorganisms that will ultimately result in good quantities of enzyme production. The ingredients of the medium should be readily available at low cost and are nutritionally safe. Some of the commonly used substrates for the medium are starch hydrolysate, molasses, corn steep liquor, yeast extract, whey, and soy bean meal. Some cereals (wheat) and pulses (peanut) have also been used. The pH of the medium should be kept optimal for good microbial growth and enzyme production.

Production process:

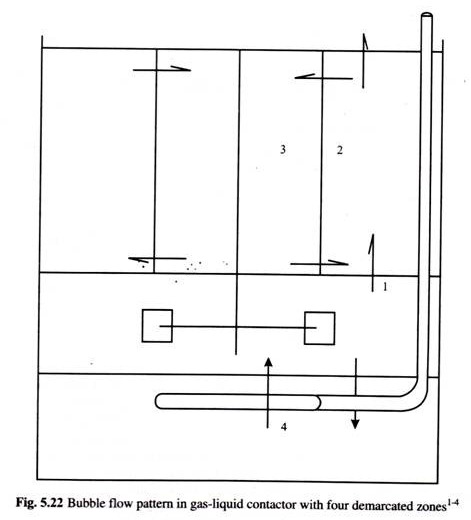

Industrial production of enzymes is mostly carried out by submerged liquid conditions and to a lesser extent by solid-substrate fermentation. In submerged culture technique, the yields are more and the chances of infection are less. Hence, this is a preferred method. However, solid substrate fermentation is historically important and still in use for the production of fungal enzymes e.g. amylases, cellulases, proteases and pectinases.

The medium can be sterilized by employing batch or continuous sterilization techniques. The fermentation is started by inoculating the medium. The growth conditions (pH, temperature, O2 supply, nutrient addition) are maintained at optimal levels. The froth formation can be minimised by adding antifoam agents.

The production of enzymes is mostly carried out by batch fermentation and to a lesser extent by continuous process. The bioreactor system must be maintained sterile throughout the fermentation process. The duration of fermentation is variable around 2-7 days, in most production processes. Besides the desired enzyme(s), several other metabolites are also produced. The enzyme(s) have to be recovered and purified.

Recovery and purification of enzymes:

The desired enzyme produced may be excreted into the culture medium (extracellular enzymes) or may be present within the cells (intracellular enzymes). Depending on the requirement, the commercial enzyme may be crude or highly purified. Further, it may be in the solid or liquid form. The steps involved in downstream processing i.e. recovery and purification steps employed will depend on the nature of the enzyme and the degree of purity desired.

In general, recovery of an extracellular enzyme which is present in the broth is relatively simpler compared to an intracellular enzyme. For the release of intracellular enzymes, special techniques are needed for cell disruption. The reader must invariably refer them now and learn all the details, as they form part of enzyme technology. Microbial cells can be broken down by physical means (sonication, high pressure, glass beads). The cell walls of bacteria can be lysed by the enzyme lysozyme. For yeasts, the enzyme β-glucanase is used. However, enzymatic methods are expensive.

The recovery and purification (briefly described below) steps will be the same for both intracellular and extracellular enzymes, once the cells are disrupted and intracellular enzymes are released. The most important consideration is to minimise the loss of desired enzyme activity.

Removal of cell debris:

Filtration or centrifugation can be used to remove cell debris.

Removal of nucleic acids:

Nucleic acids interfere with the recovery and purification of enzymes. They can be precipitated and removed by adding poly-cations such as polyamines, streptomycin and polyethyleneimine.

Enzyme precipitation:

Enzymes can be precipitated by using salts (ammonium sulfate) organic solvents (isopropanol, ethanol, and acetone). Precipitation is advantageous since the precipitated enzyme can be dissolved in a minimal volume to concentrate the enzyme.

Liquid-liquid partition:

Further concentration of desired enzymes can be achieved by liquid-liquid extraction using polyethylene glycol or polyamines.

Separation by chromatography:

There are several chromatographic techniques for separation and purification of enzymes. These include ion-exchange, size exclusion, affinity, hydrophobic interaction and dye ligand chromatography .Among these, ion- exchange chromatography is the most commonly used for enzyme purification.

Drying and packing:

The concentrated form of the enzyme can be obtained by drying. This can be done by film evaporators or freeze dryers (lyophilizers). The dried enzyme can be packed and marketed. For certain enzymes, stability can be achieved by keeping them in ammonium sulfate suspensions.

All the enzymes used in foods or medical treatments must be of high grade purity, and must meet the required specifications by the regulatory bodies. These enzymes should be totally free from toxic materials, harmful microorganisms and should not cause allergic reactions.

Regulation of Microbial Enzyme Production —General Considerations:

A maximal production of microbial enzymes can be achieved by optimising the fermentation conditions (nutrients, pH, O2, temperature etc.). For this purpose, a clear understanding of the genetic regulation of enzyme synthesis is required. Some of the general aspects of microbial enzyme regulation are briefly described.

Induction:

Several enzymes are inducible i.e. they are synthesized only in the presence of inducers. The inducer may be the substrate (sucrose, starch, galactosides) or product or intermediate (fatty acid, phenyl acetate, xylobiose). A selected list of inducible enzymes and the respective inducers is given in Table 21.4.

The inducer compounds are expensive and their handling (sterilization, addition at specific time) also is quite difficult. In recent years, attempts are being made to develop mutants of microorganisms in which inducer dependence is eliminated.

Feedback repression:

Feedback regulation by the end product (usually a small molecule) significantly influences the enzyme synthesis. This occurs when the end product accumulates in large-quantities. Large scale production of feedback regulated enzymes is rather difficult. However, mutants that lack feedback repression have been developed to overcome this problem.

Nutrient repression:

The native metabolism of microorganism is so devised that there occurs no production of unnecessary enzymes. In other words, the microorganisms do not synthesize enzymes that are not required by them, since this is a wasteful exercise. The inhibition of unwanted enzyme production is done by nutrient repression. The nutrients may be carbon, nitrogen, phosphate or sulfate suppliers in the growth medium. For large scale production of enzymes, nutrient repression must be overcome.

Glucose repression is a classical example of nutrient (more appropriately catabolite) repression. That is in the presence of glucose, the enzymes needed for the metabolism of rest of the compounds are not synthesized. Glucose repression can be overcome by feeding of carbohydrate to the fermentation medium in such a way that the concentration of glucose is almost zero at any given time. In recent years, attempts are being made to select mutants that are resistant to catabolite repression by glucose. For certain microorganisms, other carbon sources such as pyruvate, lactate, citrate and succinate also act as catabolite repressors.

Nitrogen source repression is also observed in microorganisms. This may be due to ammonium ions or amino acids. Most commonly inexpensive ammonium salts are used as nitrogen sources. The repression by ammonium salts can be overcome by developing mutants resistant to this nitrogen source.

Genetic Engineering for Microbial Enzyme Production:

Enzymes are the functional products of genes. Therefore, theoretically, enzymes are good candidates for improved production through genetic engineering. During the past 15 years, the advances in the recombinant DNA technology have certainly helped for increasing the microbial production of commercial enzymes. It is now possible to transfer the desired enzyme genes from one organism to the other. Once an enzyme with a potential use in industry is identified, the relevant gene can be cloned and inserted into a suitable production host.

Cloning strategies:

A diagrammatic representation of a cloning strategy for industrial production of enzymes is given in Fig. 21.2. This involves the development of cDNA library for the mRNA, and creation of oligonucleotide probes for the desired enzyme. On hybridization with oligonucleotide probes, the specific cDNA clones can be identified.

The next step is the transformation of industrially important host organism (e.g. Aspergillus oryzae) for the production of the desired enzyme. By this approach, it is possible to manufacture high quality industrial enzymes. A couple of enzymes produced by employing cloning strategies are described below.

1. The enzyme lipolase, found in the fungus Humicola languinosa is very effective to remove fat stains in fabrics. However, industrial production of lipolase by this organism is not possible due to a very low level of synthesis. The gene responsible for lipolase was isolated, cloned and inserted into Aspergillus oryzae.

Thus, large scale production of this enzyme was successfully achieved. Lipolase is very stable and resistant to degradation by proteases that are commonly used in detergents. All these properties make lipolase a strong candidate for its use fabric washing.

2. Rennet (chymosin) is an enzyme widely used in making cheese. It is mainly obtained from the stomachs of young calves. Consequently, there is a shortage in its supply. The gene for the synthesis of chymosin has been cloned for its large scale production.

Protein engineering for modification of industrial enzymes:

It is now possible to alter the structure of a protein/enzyme by protein engineering and site- directed mutagenesis .The changes in the enzymes are carried out with the objectives of increased enzyme stability and its catalytic function, resistance to oxidation, changed substrate preference and increased tolerance to alkali and organic solvents.

By site- directed mutagenesis, selected amino acids at specific positions (in enzyme) can be changed to produce an enzyme with desired properties. For instance, protein engineering has been used to structurally modify phospholipase A2 that can resist high concentration of acid. The modified enzyme is more efficiently used as a food emulsifier. Genetic engineering has tremendous impact on the industrial production of enzymes with desired properties in a cost-effective manner.