I.I. Esen

Department of Civil Engineering Kuwait University, P.O. Box 5969 Safat 13060, Kuwait

Abstract:

Since the early 1970s, Kuwait has done pioneering work on the collection, treatment and reuse of wastewater. With the increase in population and freshwater consumption, the capacity of existing treatment plants has increased and construction of new treatment plants is planned.

Extensive work is being done for the reuse of treatment effluents, especially for landscape irrigation. This report presents an overview of the quality and quantity of municipal wastewater generated, and excess sludge produced in Kuwait.

Introduction:

Presently, more than 500,000 m3 of fresh water is produced by the Ministry of Electricity and Water in Kuwait. About 65 per cent of the potable water used is treated in three wastewater treatment plants owned and operated by the Ministry of Public Works.

The influent wastewater can be classified as considerably strong, however, through the extended aeration process followed by filtration and chlorination in the treatment plants, an excellent quality effluent suitable to be used for irrigation is produced.

Significant quantities of sludge are produced in the treatment plants. A large fraction of the sludge solids are observed to be biodegradable. Among the heavy metals, only zinc was observed to be found in significant quantities in the sludge solids in any of the treatment plants. Regarding the chlorinated hydrocarbons, lindane was relatively high in all the treatment plants.

At present, construction of the Rekka treatment plant extension is in progress extension of the treatment plant incorporates aerobic digestion for the treatment of sludge. Since available energy is inexpensive, and total stabilization of the sludge and beneficial reuse of solids are desired, the process of aerobic digestion was selected for this specific treatment plant.

The properties of municipal wastewater and excess sludge produced are presented in the following sections.

Municipal Wastewater:

Potable water is produced and distributed by the Ministry of Electricity and Water in Kuwait. Most of the water is produced by distillation, and is mixed with a small percentage of brackish water. In some areas of Kuwait, there is a separate brackish water network. In the past forty years, production of freshwater has increased about one- hundred-fold. Table 1 shows the production and per capita consumption of fresh water since 1957.

Presently, wastewater constitutes about 65 per cent of the potable water used. Wastewater is collected through an extensive sewer network with a total length of 5200 km. Since the land area is flat, frequent pumping of sewage is necessary. For this purpose, 56 secondary pumping stations and 17 main pumping stations are used.

Wastewater thus collected is conveyed to three municipal wastewater treatment plants for treatment and subsequent reuse or disposal. The three treatment plants are referred to as the Ardiya, Rekka and Jahra treatment plants. Present values of daily inflow to these treatment plants are summarized in Table 2.

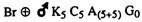

Figures 1 and 2 show the flow diagram for the Ardiya and Rekka treatment plants. Ardiya is the largest treatment plant in Kuwait and is designed as a conventional two- stage activated sludge system. The plant was designed so as to withdraw the excess sludge from the first settling basin only, but later modifications allowed sludge to withdrawn from the second settling basin as well.

Aeration was achieved by subsurface aerators. When the inflow exceeded the design capacity, a similar system was constructed as an extension to the Ardiya plant. A significant difference between the initial plant and the extension is that mechanical aeration was used in the extension but not in the initial plant.

In both systems, the excess sludge is first pumped to primary thickeners. The thickened sludge is pumped to first-stage anaerobic digesters from which it flows to a second-stage digester, post thickeners and to sludge drying beds or to mechanical dewatering systems.

The Rekka treatment plant is designed as an extended aeration activated sludge system. Long detention times allow complete oxidation of the organic matter and stabilization of the microorganism mass. Presently, the excess sludge of the system is first conveyed to gravity thickeners and then to sand drying beds. The Jahra treatment plant is similar to the Rekka plant with some modifications to allow for grit removal and different topographical conditions.

The wastewater treatment plants are owned and operated by the Ministry of Public Works (MPW). The MPW continuously monitors the characteristics of the wastewater streams at the treatment plants. Herein the results are reported of a study made at Kuwait University based on MPW data collected between July 1974 and September 1975; and data on influent wastewater collected between November 1986 and June 1988.

The data collected from July 1974 to September 1975 on influent sewage at the Ardiya treatment plant (shown in Figures 3 to 11) as total solids, total suspended solids, BOD, COD, pH, temperature, ammonia nitrogen, phosphate and dissolved oxygen, respectively. The data are plotted on normal probability paper, and for all these parameters it can be concluded that the distribution of the variables approximately follows normal probability distribution.

Figures 12 to 18 show the variation in BOD, COD, pH, temperature, ammonia nitrogen, sulphate and chloride measured in the influent wastewater at Ardiya between November 1986 and June 1988. In this study, no attempt was made to assess the distribution of the parameters, and the data was presented as a time-series representation.

Table 3 presents a summary of the average values of the water quality parameters measured in the two study periods. As can be observed, within a period of about 12 yr, the values of solids, COD and phosphate significantly decreased. Nevertheless, Kuwaiti sewage can still be classified as strong according to the guidelines given by Metcalf and Eddy, Inc. (1979).

Table 4 gives the average values of the water quality parameters measured in the influent wastewater at Rekka during the first ten months of 1996. These values are similar to those at Ardiya with the possible exception of the values for dissolved solids and ammonia nitrogen.

Figures 19 and 20 show the variation in the average daily inflow in 1996, and the variation in the total suspended solids, COD, BOD, and grease and oil between 1993 and 1996, at Rekka respectively.

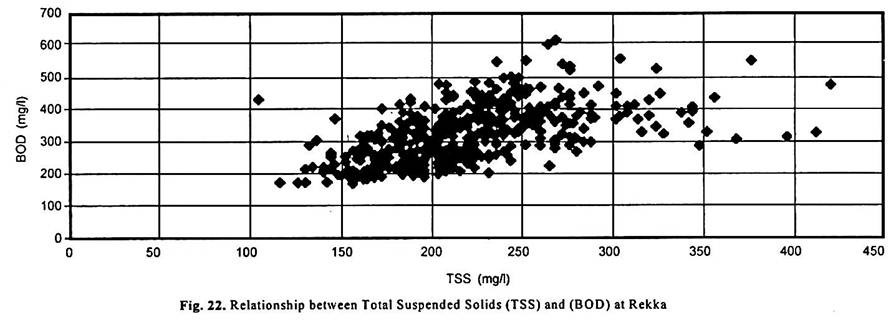

Figures 21-25 show the relationship between various water quality parameters at Rekka as determined by the Ministry of Public Works (1996). The approximately linear relationships between COD and BOD, and between suspended solids and BOD or COD are interesting to note.

Sludge Production:

A major study was made at the Kuwait Institute for Scientific Research between 1984 and 1986, to assess the quality and quantity of sludge produced in the three treatment plants. The findings of Ghobrial (1986) are briefly summarized.

Based on the assumption of constant sludge age, or solids retention time, the quantity of solids produced at the three treatment plans was estimated for the period between 1985 and 2020. The results are shown in Table 5.

An extensive sampling program was initiated between October 1984 and March 1985. Sludge samples were collected at two points at each of the three treatment plants. These are denoted as L1 (before thickener) and L2 (after thickeners at Rekka and Jahra, and after anaerobic digesters at Ardiya).

Figure 26 shows the particle size distribution of the solids. The solids were classified as colloidal, fragile or rigid. Colloidal solids constituted that fraction of the solids smaller than 0.8 mm. The sand content of the solids was determined as 25-30 per cent in all the plants.

Figures 27 and 28 show the variation in the sludge volume index and specific resistance to filtration. It should be noted that if the sludge volume index is less than 100 ml/g, the sludge is expected to exhibit good settling characteristics. However, a meaningful interpretation of the sludge volume index is possible if the initial solids concentration is less than 10 g/1, which was not the case in this study.

Nevertheless, sludge volume index values were observed to be higher at Jahra. On the other hand, specific resistance to filtration was higher at Ardiya. This can be attributed to the high percentage of colloidal solids at Ardiya, as shown in Fig. 26.

Figures 29 and 30 show the total dry solids and total volatile solids, respectively. The ratio of volatile suspended solids to total dry solids is about 70 per cent, which indicates that a large fraction of the sludge solids is biodegradable.

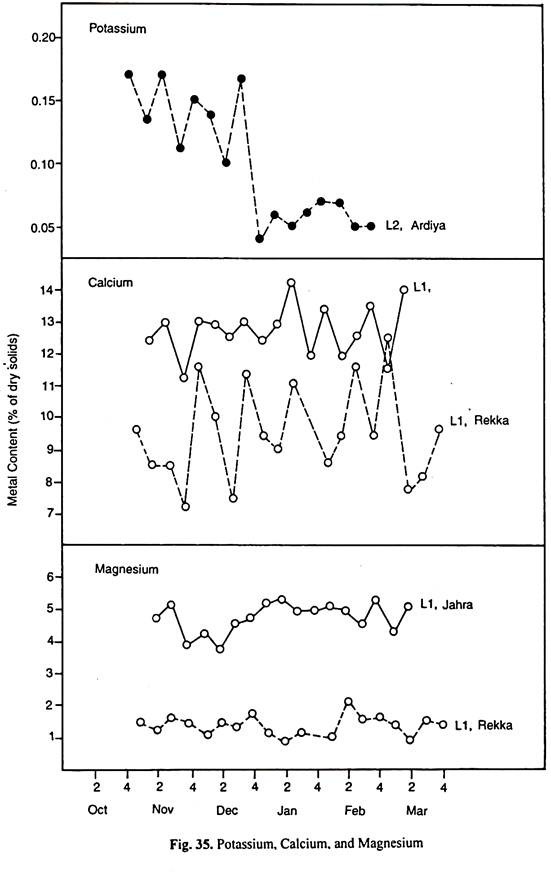

Figures 31 to 35 show the hydrogen sulphide, phosphorous and nitrogen, chloride ion, alkalinity, and potassium, calcium and magnesium concentrations, respectively. Hydrogen sulphide indicates that anaerobic degradation is taking place, and further handling of the sludge will cause odour.

Phosphorous and nitrogen indicate the nutritive value of sludge as a soil conditioner, and chloride indicates the value of sludge as a soil conditioner after dewatering. Alkalinity affects the behaviour of sludge undergoing dewatering by sedimentation, filtration and centrifugation, and it influences the polymer dosage to be applied.

Similarly, calcium, magnesium and potassium concentrations help in determining the dosage of sludge to be applied as a soil conditioner. Except for hydrogen sulphide, Jahra sludge showed highest concentrations in all these parameters.

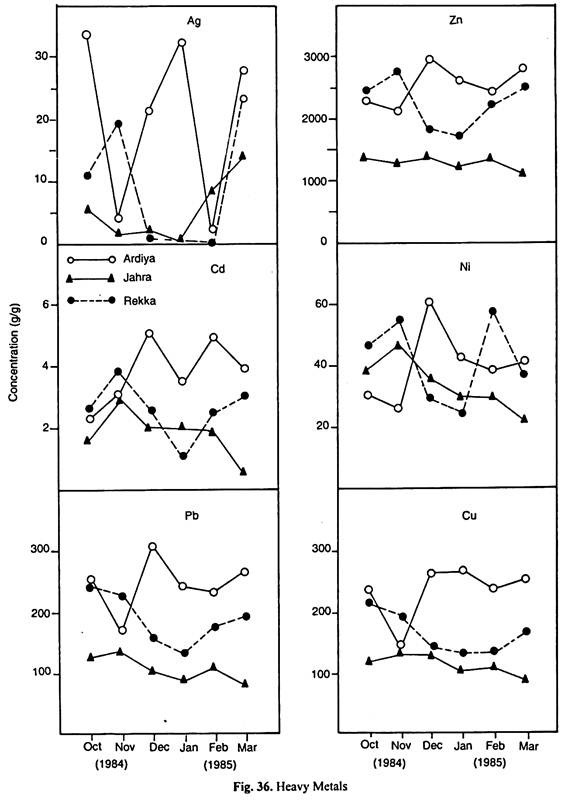

Figures 36 and 37 show the heavy metal concentrations in the sludge, and Fig. 38 shows the chlorinated hydrocarbons. Among these, zinc, copper and nickel are toxic to plants; cadmium accumulates in the edible parts of plants which in turn become harmful to mammals consuming the plants; and mercury, silver and lead have adverse effects on the marine environment. Zinc was the only heavy metal which was observed to be found in significant quantities in any of the treatment plants.

Chlorinated hydrocarbons have low water solubility, long half-lives, and they are toxic to mammals. Figure 38 shows the concentrations of six selected chlorinated hydrocarbons. Among these, polychlorinated biphenyls (PCB) were observed to be high at Rekka, and lindane was relatively high at all the treatment plants.

The Rekka Treatment Plants Extension:

Presently, about 90,000 m3/d of domestic wastewater is treated at the Rekka plant. Considering the recent increases in water consumption and wastewater generation, the capacity of the plant will be increased to 180,000 m3/d. The process will continued to be extended aeration followed by filtration and dual-point chlorination.

The influent BOD is about 80 per cent soluble, and the design allows for a 24-h hydraulic residence time and a 12-h solids retention time. The plant performance is shown in Table 6.

In areas having climatic conditions similar to those of Kuwait, it is usually difficult to estimate sludge drying rates, grit volumes in sludge, the temperature of mixed liquor in the aeration tasks, and the overall sludge production rate through generally accepted design procedures. If available energy is inexpensive, and if total stabilization of the sludge and beneficial reuse of solids are desired, aerobic digestion presents itself as a viable alternative.

For the reasons mentioned above, the Rekka treatment plants extension incorporates aerobic digestion for the treatment of the sludge produced. Sludge will be first thickened by two gravity thickeners, then digested through four digesters with dimensions of 92 + 23 + 4.8 m. Subsurface aeration will be provided by three blowers (one of them as a standby) rated at 2.2 MW each. Finally, the digested sludge will be conveyed to drying beds. The plant will have totally automated control.