Microbial Production of Fermented Foods!

It is estimated that about 20-30% of the household budget is spent towards foods in the developed countries. This may be a little less in the developing nations. Therefore, food and beverage biotechnology occupies a prominent place world- over.

There are records that man was making bread, wine, curd etc., as early as 4000 BC. These processes, collectively referred to as traditional or old biotechnology, mostly employed for the preparation of foods and beverages, were based on the natural capabilities of the microorganisms (although their existence was unknown at that time).

With the advances made in microbiology and recently biotechnology, food and beverage production is a major industry. Food biotechnology is also concerned with the improved quality, nutrition, consistency, colour, safety and preservation of foods, besides making them available round the year (Note: Most foods are seasonal in nature and therefore as such are not available throughout the year). In addition, modern biotechnological processes also take into account the health aspects of the people.

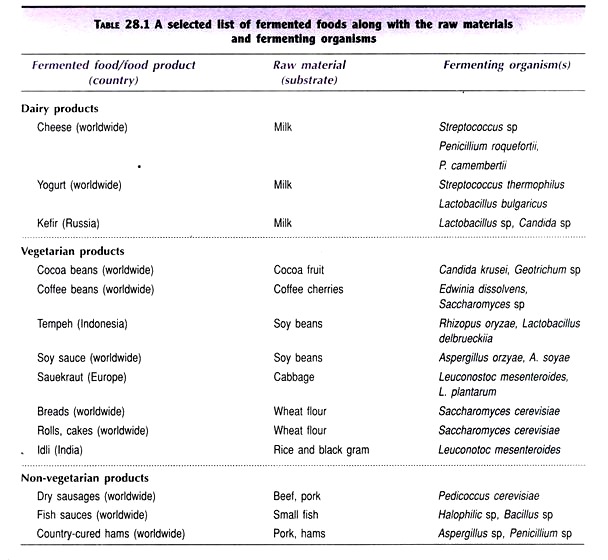

The production of fermented foods is variable. This depends on geographical region, availability of raw materials, traditions and food habits of the people. A selected list of fermented foods along with raw materials and fermenting microorganisms is given in Table 28.1.

Advantages of Fermented Foods:

i. Enhanced nutritive value.

ii. Increased digestibility.

iii. Improved flavour and texture.

iv. Serve as supplements in preparing several dishes.

Besides the list given in Table 28.1, there are many other compounds that are directly or indirectly used as food supplements which must also be referred by the reader. These include vitamins, amino acids, organic acids, enzymes biopolymers, single –cell protein and mushrooms.

1. Cheese:

Cheese production is the largest dairy industry in the world. There are around 1,000 types of different cheeses. They are broadly of two types — un-ripened cheeses (cottage cheese with low fat, cream cheese with high fat) and ripened cheeses (hard cheese e.g. cheddar, blue cheese; soft cheese e.g. limburger, camembert). Irrespective of the type of the cheese, all of them are invariably made from the casein of milk that is produced after separating the whey (liquid portion of milk). Milk from different animals can be used e.g. sheep, cow, goat, buffalo.

Historical perspective:

The use of animal stomachs for carrying liquids is centuries old. When milk was transported in this fashion, the formation of solids (that were tasty) was observed. The solids were concentrated after draining liquids. These solids were salted and consumed later. A good example of food preservation, long ago! We now know that this solid portion is the cheese. It is produced by the combined action of enzymes (rennet) of the stomach living and the bacterial contamination.

Production process:

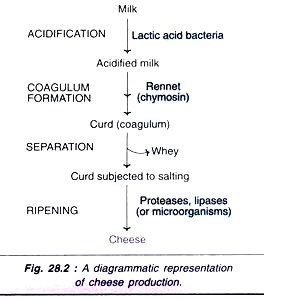

As already stated, cheese is produced from milk. This is carried out by a process of dehydration wherein casein (milk protein) and fats are concentrated 5-15 fold. Cheese production is very complicated, and broadly involves four stages- acidification of milk, coagulum formation, and separation of curd from whey and ripening of cheese.

1. Acidification of milk:

By employing lactic acid bacteria (Streptococcus lactis, Lactobacillus lactis) the sugar of milk (lactose) can be converted to lactic acid. This lowers the ph to around 4.6, and thus acidifies milk.

2. Coagulum formation:

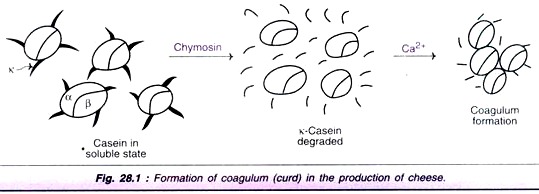

When the acidified milk is treated with rennet (i.e. the enzyme chymosin of animal or fungal origin), casein gets coagulated. Casein mainly consists of three components-insoluble α and β caseins and a k-casein that keeps them in soluble state. By the action of chymosin, k-casein is degraded. Consequently, α and β caseins and the degraded products of k casein combine to form a coagulum (curd) (Fig. 28.1). This process of coagulation is dependent on calcium ions.

3. Separation of curd from whey:

When the temperature of the coagulum is raised to around 40°C; the coagulum (curd) and whey (fluid portion) get separated. The separated curd is cut into blocks, drained and pressed into different shapes.

4. Ripening of cheese:

The flavour of raw cheese (with rubber texture) such as cheddar is bland. Ripening imparts flavours, besides making changes in its texture. The procedures adopted for ripening (or maturation) are highly variable depending on the type of cheese to be prepared. The blocks of curd separated are subjected to the action of proteases and/or lipases.

Alternatively, they may be inoculated with certain fungi (e.g. Penicillium roquefortii). The hydrolysis of proteins and fats (either by enzymes or microorganisms) results in certain compounds which imparts flavour to the cheese. Mild hydrolysis of fats (or cheese), usually carried out by lipases or Aspergillus nigeror Mucor maihai results in butyric acid formation with characteristic flavour.

A diagrammatic representation of cheese production is depicted in Fig. 28.2.

Sources of chymosin for cheese production:

There are several sources of rennet (chymosin enzyme) for cheese production. These include calves, adult cows, pigs and fungal sources. Fortunately, the fungal (e.g. Mucor meihei) sources of chymosin are almost comparable to the animal sources and are widely used in some countries. However, some people always prefer animal rennet used cheese due to its slight superior flavour.

Genetically engineered microorganisms for chymosin:

Some workers could successfully clone the genes of animal chymosin and transfer the same into microorganisms. The chymosin so produced by genetic manipulation is very widely used these days in some countries. The taste of cheese manufactured by microbial chymosin (i.e. genetically engineered) and the animal chymosin are identical. Public as well as the vegetarian societies in some countries have accepted the cheese produced by the genetic manipulation of the enzyme, chymosin.

2. Yoghurt:

Yoghurt is produced by fermenting whole milk by employing a mixed culture of Lactobacillus bulgaricus and Streptococcus thermophilus. While L. bulgaricus produces acetaldehyde that imparts a characteristic taste, S. thermophilus results in the formation of lactic acid to give acid flavour.

In addition, both these bacteria produce extracellular polymers that increase the viscosity of the fermented milk. Yoghurt is very delicious and in fact frozen yoghurt is becoming popular as an alternative to ice cream.

3. Sauerkraut:

Sauerkraut is prepared in most western countries. It is a fermented and preserved form of cabbage. The shredded cabbage is mixed with salt (approximately at 2.5% concentration) and packed anaerobically. High salt concentration promotes leakage of sugars from the cabbage while reducing the water activity.

As the growth of the lactic acid bacteria occurs, the pH is lowered. At this low pH, the purifying bacteria cannot grow. In this way, sauerkraut can be preserved for long. Sauerkraut is nutritious as well as delicious. The traditional pickles (mango, lemon, etc.) in India are also good examples of fermentation and preservation, based on the principles of biotechnology.

4. Bread:

Bread making from the dough by employing microorganisms is one of the oldest examples of fermentation processes known to mankind. There is evidence that bread was prepared in Egypt in 3000 BC. Primarily, bread is a fermented product of cereal flours such as wheat and rye. The cereal flour mixed with water, salt, sugar, fat and other ingredients (as desired for enrichment of bread) is subjected to fermentation by yeast, Saccharomyces cerevisiae (top fermenting strain). The main reaction that occurs during bread formation is the fermentation of hexoses to CO2 and ethanol.

C6H12O6 → 2C2H5OH + 2CO2

The ethanol produced either gets evaporated or forms esters. The CO2 gets entrapped in the dough resulting in its expansion. The expansion and stretching of the dough, particularly with wheat is due to the unique elastic protein namely gluten. Gluten is mainly responsible for retaining the shape of bread. Besides yeast enzymes, the enzymes (e.g. amylases) of other microorganisms also help in fermentation and baking of bread. The texture of bread is influenced by fats and emulsifiers added to the dough.

The bread making is carried out with three objectives:

i. Good leavening due to CO2 formation.

ii. Flavour development.

iii. Good texture.

The yeast fermented bread has the above characteristics. This is in contrast to the bread produced with baking powder which also produces CO2. But this does not have the same flavour and texture as that produced by yeast. Thus the yeast, which is appropriately referred to as baker’s yeast is a package of enzymes to give a desired product.

In recent years, some workers have reported the development of genetically engineered strains of Saccharomyces cerevisiae with improved fermentation properties. Such organisms, when used in baking industry, are believed to further enhance the quality of bread with regard to flavour, texture etc.

Sour-dough breads:

In some parts of the world, sour breads are prepared by using the yeast, Candida milleri and bacterium, Lactobacillus San Francisco.

Baker’s Yeast:

The living cells of aerobically grown Saccharomyces cerevisiae are collectively referred to as baker’s yeast. Baker’s yeast is commercially available either as a dried powder i.e. dry yeast with about 95% dry weight or in the form of cakes (about 25-30% dry weight). These commercially available yeast preparations can be used in bread making.

Production of baker’s yeast:

The medium for baker’s yeast production contains molasses, ammonium salts (or ammonia), vitamins, phosphates and antifoam agents. Sugar cane or sugar beet molasses can be used. A commercially available molasses with a sugar concentration of 45-50% is usually preferred. Baker’s yeast production is carried out by an aerobic fed-batch process.

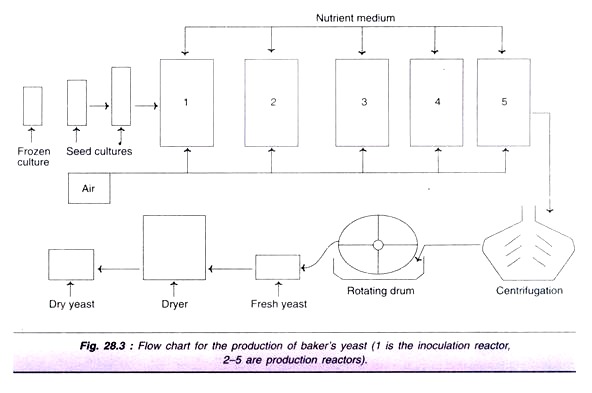

The flow chart for the production of baker’s yeast is depicted in Fig. 28.3. The actual production process and the strain of Saccharomyces cerevisiae used depend on the company. The desired strain is maintained in a frozen state. The inoculum is prepared in stages so that large volumes are finally obtained.

From the inoculation reactor (fermenter), the culture is transferred to production reactors. The process is carried out in air-lift or bubble column type reactors at pH 4-5, temperature 28-30°C for about 12-18 hours. The yeast cells are washed, centrifuged and then dewatered on a rotating drum. The fresh yeast obtained can be either directly used or dried and stored.

The yeast cells may be mixed with plasticizer (e.g. vegetable oil) and prepared in a block form. This block can be cut into small pieces, wrapped and stored (at -4°C) until used. The samples of yeast are usually tested for baking properties before they are put in use.

Other Vegetarian Products:

Besides the bread which is consumed worldwide, there are several other vegetarian fermented foods. These include rolls and cakes (worldwide) soy sauce (worldwide) idli (India) and tempeh (Indonesia).

Coffee, Tea and Cocoa:

Coffee, tea and cocoa are very popular nonalcoholic fermented beverages, and extensively consumed throughout the world. When the tea leaves are crushed, the chemical components of tea are released by enzymatic activity. For coffee and cocoa, a natural fermentation process (by bacteria, yeast and fungi) on the pulp surrounding beans results in the development of flavour and aroma.

The exact nature of the fermentation processes involved in tea, coffee and cocoa are not fully known. The dried products namely tea leaves, and coffee and cocoa beans are commercially available for beverage preparation.

Sweeteners:

Sweeteners occupy a prominent place in food consumption, by all the people. The most predominantly used natural sweetener is sucrose (obtained from sugar cane or beet). Sweeteners are invariably required for the preparation of soft drinks, ice creams, jams, jellies, sauces, bread, confectionery, pickles etc. Hence there is a continuous search for low calorie sweeteners.

Saccharin, a chemically synthesized sweetener (300 times sweeter than sucrose) was used for several years, and its use is now being restricted due to certain adverse health effects. High fructose corn syrup (HFCS), produced from sucrose is sweeter (1.5 times) than sucrose. Aspartame (aspartyl phenylalanine) is a product of innovative biotechnology. It is about 200 times sweeter than sucrose and is truly a low calorie sweetener. Aspartame is approved for human consumption and is widely used in soft drink and other industries.

Thaumatin-A Sweet Protein:

Thaumatin is a protein extracted from the berries of the Thaumatococcus daniellii, a native plant in Africa. Thaumatin is about 3000 times sweeter than sucrose. Thaumatin certainly appears to be a good sugar substitute and a low-calorie sweetener. It is in fact being used as a sweetener and flavour enhancer of various foods. At least five different forms of thaumatins with a molecular weights in the range of 20,000-22,000 have been isolated and characterized.

Genetic engineering to produce thaumatin:

Natural production of thaumatin is very limited and therefore can never meet the demands of consumption. Biotechnological production of this sweetener is the method of choice for its large scale manufacture. Thaumatin-encoding mRNA species have been isolated, identified and converted to cDNA and finally to double-stranded DNA. These DNAs were cloned and transferred to E. coli. But the yield of thaumatin production was very low. Attempts were also made to express thaumatin genes in yeasts such as S. cerevisiae and Kluyveromyces lactis. Some success has been reported in this direction.

Monellin-A Candidate for Sugar Substitute:

Monellin is a protein found in the fruit of an African plant Discorephyllum cumminsii. It is about 100,000 times sweeter than sucrose (on molar basis). Monellin is dimer composed of an A-chain (45 amino acids) and a B-chain (50 amino acids). This protein is optimally sweet when both the chains are held together and not when they are separated.

It has been possible to chemically synthesize a gene that encodes both A and B chains as a single polypeptide. This gene was in fact introduced and expressed in tomatoes for the production of monellin. However, the success has been very limited.

Flavour Enhancers:

Taste and flavour are very important for the acceptability of foods. Monosodium glutamate is the most commonly used flavour enhancer. Its production and other aspects are described elsewhere. The degraded products of proteins and RNAs also impart flavour. Thaumatin and monellin (described above) are also flavour enhancing agents, besides sweetening.

The other flavouring agents are citric acid (produced by Aspergillus niger), acetone and butanol (produced by Clostridium acetobutylicum). The lactones formed by some microbial fermentations also enhance flavour e.g. y-butyrolactone produced in yeast fermentation of wine and beer. Mention must be made about alcohol also which can increase flavour and taste when added at appropriate concentrations e.g. certain medicinal syrups.