Read this article to learn about the production of biogas from biomass. The two methods are: (1) Microbial Production of Methane (Biogas) and (2) Biogas Production by Biogas Plant.

Biogas:

Biogas is a mixture of gases composed of methane (50-80%), carbon dioxide (15-40%), nitrogen (4%) and hydrogen sulfide (1%) with traces of hydrogen, oxygen and carbon monoxide. There are many other common names for biogas— gobar gas, sewage gas, klar gas and sludge gas. Biogas is a gaseous fuel and serves as a good source of energy for various purposes.

1. It can be used for cooking purposes (on combustion).

2. Gobar gas can generate electricity.

3. It can be purified to yield good grade methane. Methane gas is extensively used as a fuel for domestic and industrial purposes. It is employed for the generation of electrical, mechanical and heat energy.

It is estimated that under ideal conditions, 10 kg of biomass can produce 3m of biogas. This biogas can provide 3 hour cooking, 3 hour lighting or 24 hour refrigeration (with suitable equipment). The calorific value of biogas (with 80% methane) is around 8,500 cal/m3.

Biogas Production in Different Countries:

Biogas production significantly contributes to world’s energy source. China has the largest number of biogas or gobar gas systems, with an estimated 7 million units. Government of China encourages and offers subsidies for construction of biogas units. As a result, the cost of a biogas plant is cheaper than a bicycle in China!

Governments in many developing countries also encourage installation of biogas plants. In India, Government provides 25% subsidy, besides encouraging banks to offer loans for construction of biogas plants. They are becoming popular in rural areas. Pakistan also has a good number of gobar gas plants.

Substrates for Biogas:

The usual substrates for biogas production are the waste products of animal husbandry, industries, agriculture and municipalities. In India and other developing countries, cattle dung (gobar) is most commonly used. The major raw material for biogas in China is pig dung.

The concentration of organic dry matter or total solids (TS) is useful for grading the industrial, agricultural and municipal wastes. Thus, low grade (< 1% TS), medium grade (1-5% TS), high grade (5- 20% TS) and solid (20-40% TS) wastes are available. Solid or high grade wastes are preferred as substrates for biogas production.

In general, most of the substrates used in biogas plants contain adequate quantities of almost all the essential nutrients required for microbial growth. If necessary, nitrogen, phosphorus and trace elements are added. A carbon nitrogen ratio (C/N) less than 40: 1 is preferred for optimal biogas formation.

Water hyacinth (Eichornia crasipes) an aquatic weed with huge biomass is a good source (raw material) for methane production. With high C/N ratio and low lignin content, the yield of methane is high. Another aquatic weed Azolla is equally important for methane generation.

Microbial Production of Methane (Biogas):

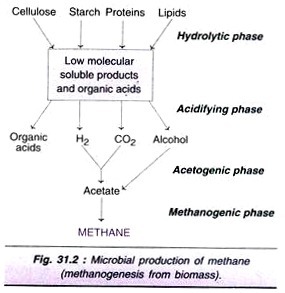

Methane is the most abundant constituent of biogas. It can also be directly used for various domestic and industrial purposes. The microbial generation of methane, appropriately referred to as methanogenesis from biomass occurs in four phases (Fig. 31.2).

1. Hydrolytic Phase:

Certain facultative anaerobic bacteria hydrolyse the complex organic materials of the biomass (cellulose, starch, proteins, and lipids) to low molecular weight soluble products and some organic acids.

2. Acidifying Phase:

This phase is characterized by more formation of organic acids, besides H2, CO2, and alcohol.

3. Acetogenic Phase:

Acetogenic bacteria convert alcohol into acetate. These bacteria also generate acetate from H2 and CO2.

4. Methanogenic Phase:

This is the actual phase of methane gas formation. The methanogenic bacteria (e.g. Methanobacterium omelianskii, M. formicicum, M. bryantii, Methanosarcina barkeri) convert acetate, and CO2 and H2 into methane.

CH3COOH → CH4 + CO2

4H2 + CO2 → CH4 + 2H2O

Some other substrates like formate and methanol can also be converted to methane.

4HCOOH → CH4 + 3CO2 + 2H2O

4CH3OH → 3CH4 + CO2 + 2H2O

The overall reaction of methane formation from glucose as the starting material may be represented as follows.

C6H12O6 → 3CH4 + 3CO2

The complex polysaccharides particularly lignin and cellulose due to their inefficient conversion, limit methane production. In the normal process of methanogenesis, approximately 50% of the complex polysaccharides contribute to methanogenesis.

Process of Biogas Production (Biogas Plant):

Biogas production from biomass is an anaerobic process. The anaerobic digestion is usually carried out by using air tight cylindrical tanks which are referred to as anaerobic digesters. A digester may be made up of concrete bricks and cement or steel, usually built underground. The digester has an inlet attached to a mixing tank for feeding cow dung (Fig. 31.3).

The methanogenic bacteria from another digester are also added with cow dung. The digester is attached to a movable gas holding or storage tank with a gas outlet. The used slurry (spent cow dung) comes out from the digester through an outlet. This can be used as a manure. The anaerobic digester described above, is a low technology gobar gas plant, commonly used for domestic purposes in rural areas in India. The process of digestion usually takes about 2-3 weeks when cow dung is used as the substrate.

Landfill Sites for Methane Production:

Landfill sites are low cost digesters built underground for the digestion of solid wastes (of industries and municipalities). As the anaerobic digestion of solid organic material occurs, methane gas is generated. It can be recovered by boring gas wells into the top of the landfill.

Factors Affecting Biogas (Methane) Production:

The factors affecting methane production, with special reference to biogas plant, are briefly described.

1. Temperature and pH:

The ideal temperature is 30-40°C, while the pH is 6-8, for good yield.

2. Slurry composition:

The ratio between solid and water composition in the slurry should be around 1: 1. A carbon nitrogen ratio of 30: 1 in the slurry results in optimal methane production. Good mixing and solubilization of the organic constituents is required.

3. Anaerobic conditions:

The digester should be completely airtight, so as to create suitable anaerobic conditions.

4. Presence of inhibitors:

Ammonium sulfate and antibiotics inhibit methane production. Agricultural wastes, pig and chicken manure (generating ammonia) and wastes from paper (rich in sulfate) inhibit biogas production.

Advantages of Biogas Production:

By using a simple technology, agricultural, industrial and municipal wastes can be converted into a biofuel. The left over residue after biogas formation can be used as fertilizers. Thus, the waste materials that would cause environmental pollution are fruitfully utilized for biogas and fertilizer production.

Limitations for Large Scale Production of Methane:

Although production of methane as a constituent of biogas is ideally suited for domestic purposes.

Many people argue against the large scale commercial production of methane for the following reasons:

1. Methane is abundantly available in the natural oil and gas fields (produced by the same mechanism of methanogenesis, over a period of years).

2. Microbial production of methane is more expensive than its isolation from the natural gas.

3. Methane production by gasification of coal is more economical than its production from biomass.

4. Being a gaseous fuel, it is quite difficult as well as expensive to store, transport and distribute methane.

5. Methane is unsuitable for use as a fuel in automobiles. This is because it is very difficult to convert the gaseous methane into liquid state.

Despite the limitations listed above, production of methane from a wide range of biodegradable materials (particularly the wastes) is still attractive. This is due to the fact that the biomass used for methane generation is renewable, in contrast to the permanent depletion of naturally produced methane (in the gas and oil fields).